For speed synchronization applications like a dual belt labeling conveyor, multiple motors must run at the same speed. What is the best type of motor to use and what are the methods to achieve this? Our application engineer set up a product demonstration to show you how this can be done with one potentiometer.

What's covered?

- Application Example

- Why BLE2 Series?

- Demo Setup

- How Do I Synchronize Motor Speeds By Wiring One External Potentiometer to Multiple Drivers?

- Bonus: How Do I Synchronize the Speeds of Gear Motors with Different Gear Ratios or Pulley Diameters?

Application Example:

A dual belt, bottle labeling pinch conveyor (see below) has two motors running two belts independently at the same speed. By synchronizing the speeds of the two belts, the labels on the bottles always face the same direction while being moved by the two belts on the pinch conveyor. If there's a difference in the speed of the two belts, the "ABC" labels on each bottle would be rotated to a different angle.

Our application engineer set up a product demonstration to show a customer how the speeds between multiple BLE2 Series brushless motors can be synchronized with one external potentiometer.

Why BLE2 Series?

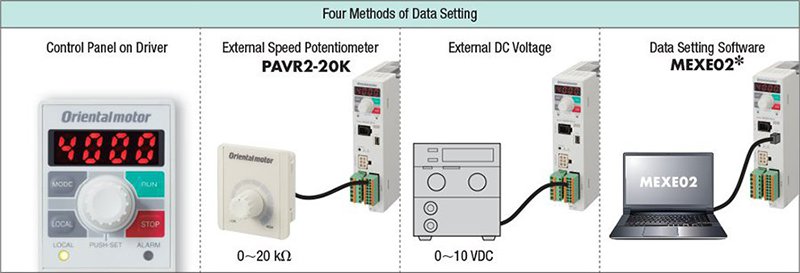

We chose the BLE2 Series brushless gear motors for its built-in closed-loop speed regulation, which is ideal for speed control applications. The BLE2 Series driver is also flexible with its speed input commands. You can set the speed by using the operation control panel on the driver, an external speed potentiometer, external DC analog voltage, or the MEXE02 software.

Of course, there are other ways to synchronize speeds between multiple motors, such as using a bigger hollow-shaft gear motor to drive both pulleys connected by another belt or using one driver to drive both motors. For some VFDs/inverters (AC motors) or brushless DC motor drivers, it can be as easy as setting the same RPM on multiple drivers. However, since brushless motors have built-in closed-loop speed regulation, the speed variance between the two belts will be much narrower than open-loop AC motors and will not be affected by load.

|

Demo Setup In this demo setup, our application engineer put 2 BLE2 Series demos side-by-side and then wired one external potentiometer to both drivers. We have one BLE2 Series brushless gear motor on the bottom-left driving a coupling, and another BLE2 Series gear motor on the top-right driving a disc/pulley. The digital speed displays on the drivers closest to the motors are set up to show the gearhead output shaft RPM as they rotate. |

|

How Do I Synchronize Motor Speeds By Wiring One External Potentiometer to Multiple Drivers?

- Wire one external potentiometer OR supply one external DC voltage analog signal to multiple drivers.

Let us explain exactly how to do this.

First, you must set the driver to accept an analog signal input to set the command speed. Change the "Speed, torque limiting command selection" parameter (ID: 1820) to "1" or "2" depending on your preference. "1" will only enable analog speed input for data #1 only. "2" will enable analog speed input for all data.

Typically, one external potentiometer is used for each driver, but in this case, we'll wire one external potentiometer to both drivers using the same input pins (VH, VM, and VL). Page 46 of the BLE2 Series operating manual (below) shows the wiring setup of the external potentiometer. Connect the 3 terminals on the external potentiometer to the VH, VM, and VL input pins on the drivers' I/O connectors. Up to 20 drivers can be connected with this method. Depending on the # of drivers, the resistance (VRx) can change. You can also do this function by supplying a variable external DC voltage instead of a potentiometer or simply setting speeds digitally.

Tests ran:

- Speed matching

- Speed matching at 80 RPM using switches

- Speed matching at 30 RPM using one potentiometer

- Speed matching at 120 RPM using one potentiometer

- Speed matching at 160 RPM using one potentiometer (120 x 20:1 = 3,200 RPM at the motor shaft)

- Consistent speed under load

- Speed matching at 30 RPM while applying load

- Speed matching at 80 RPM while applying load

Once the motors are running, Paul confirms the speeds with the digital speed displays on the drivers, which show RPM in real-time. When applying load, Paul also confirms the load by showing the Load Factor from the MEXE02 support software, which shows the actual % of rated torque being used.

While Paul is applying the load to one of the motors by hand (at the 3:23 mark), the Status Monitor in the MEXE02 software shows "command speed (motor shaft)", actual speed (motor), and Load Factor. This shows that the speeds of two brushless gear motors stay synchronized even when the load fluctuates. However, if you exceed the motor's rated torque for too long, it will alarm out eventually.

Now let's throw in a curve ball. What if you had gear motors with different pulley diameters or gear ratios? How would you synchronize the speeds then? What if you had to scale the speed of the 2nd motor by a factor of the 1st motor? Well, I'm glad you asked.

In many cases, wiring one external potentiometer is enough since people usually use the same gear motor and same pulleys to synchronize speeds. However, if you need to adjust the speed difference, or scale the speed, you'll have to access what's called the "Analog Operation Speed Command" settings on the BLE2 Series driver or via the MEXE02 support software.

Bonus: How Do I Synchronize the Speeds of Gear Motors with Different Gear Ratios or Pulley Diameters?

- Wire one external potentiometer or supply one external DC voltage analog signal to multiple drivers.

- Adjust the Analog Operation Speed Command Gain setting.

You can use the driver's front operation panel or use the MEXE02 support software to change the driver's internal parameters. 850 r/min/V is the default value for the Analog speed command gain setting.

| Using Driver's Front Operation Panel | Using the MEXE02 Support Software |

|

Under the "Speed/torque limiting adjustment"

|

Here's how you would adjust the speed difference between two motors by adjusting the Analog Operation Speed Command Gain setting (ID: 1821). You can choose a value from 0 to 4,000 RPM per volt, which sets the speed command gain per 1 VDC of the external analog input voltage. With the default value of "850 r/min/V", it means that the motor will increase its RPM by 850 RPM with an increase of 1 VDC of the external analog voltage signal. This will be necessary for the 2nd and subsequent drivers.

For example, if you were trying to synchronize the speeds of a BLE2 Series gear motor with a 20:1 gear ratio and another BLE2 Series gear motor with a 10:1 gear ratio, you would have to scale up the second 20:1 gear motor by a factor of 2, which means the second motor needs to rotate twice as fast as the first motor.

In this case, you would set the following:

- Set driver 1 parameter (ID: 1821) to "820".

- Set driver 2 parameter (ID: 1821) to "410".

This is necessary due to the difference in gear ratios. Gear motor 1 has a 20:1 gear ratio, so it needs to run twice as fast to match the RPM of Gear motor 2, which has a 10:1 gear ratio. The BLE2 Series uses a 0~5 VDC range for the analog signal.

We hope this information helps. If you need additional support, our helpful technical support team can answer your questions via phone, email, or live chat.