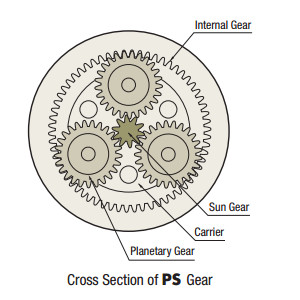

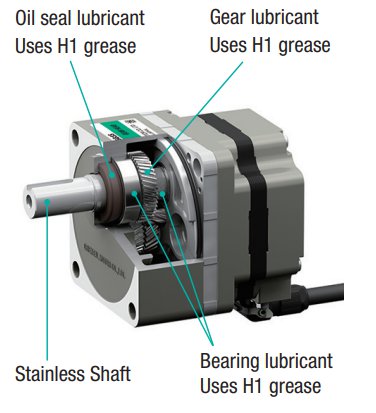

Selecting a gearhead for a stepper motor is like picking out the right shoes for the occasion. Sure, you can wear Air Jordans on a football field, but they're not better than a pair of regular cleats. Similarly, you can use a harmonic gearhead to drive a unidirectional conveyor, but you may be overpaying for its zero-backlash capability when you don't have to. Picking the right gearhead can ensure the best balance between performance and budget.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Gearhead Selection for Stepper Motors

Topics: Stepper Motors, Alphastep Hybrid Control, Motor Sizing, Gearheads, Motion Control Basics

Gearhead Selection for Brushless Motors

Gearheads play a crucial role in motor performance optimization. Each type of gear offers its own features and characteristics, and the gear ratio alters a motor's output torque and speed. By carefully selecting the optimal gear type and ratio, engineers can fine-tune motor performance to align precisely with the application requirements.

Topics: Speed Control, Motor Sizing, BLDC Motors, Gearheads, Motion Control Basics

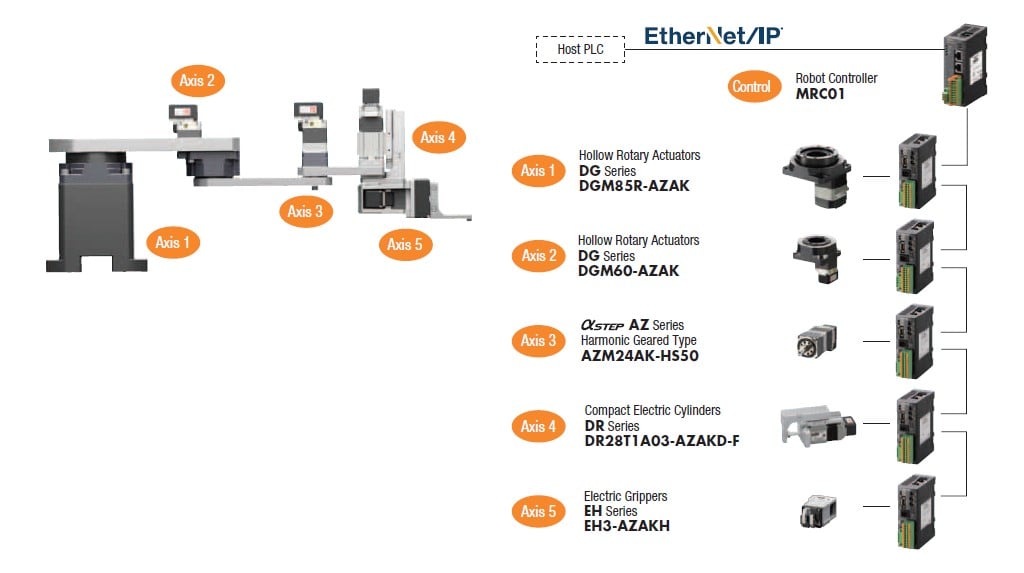

How to Build a SCARA Robot with Off-The-Shelf Products

Robotics automation can be easier to build than you think. Here's an example of how a 5-axis SCARA robot can be built in-house with off-the-shelf products.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Motor Sizing, VIDEOS, Software, Network, Application Examples, Rotary Actuators/Index Tables

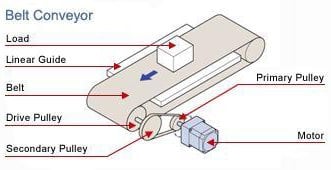

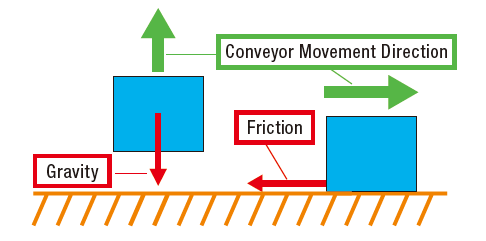

Motor Sizing & Selection Example: Variable Speed Belt Conveyor

Many motor manufacturers offer a motor sizing tool to help with product selection, but if you don't know how to use it, you may still end up paying for it in the long run.

Topics: Speed Control, Motor Sizing, BLDC Motors, Food & Packaging, Conveyors

Which type of electric motor do you size for your conveyor, XYZ table, or robot? Before you select one, you must understand the characteristics of each type of motor in the market.

Topics: AC Motors, Stepper Motors, Speed Control, Motor Sizing, BLDC Motors, Washdown, Servo Motors, Motion Control Basics, Conveyors

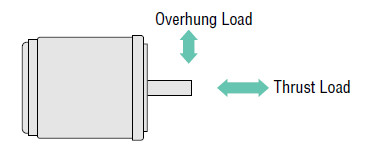

Motor Sizing Basics Part 4 - How to Calculate Radial Load and Axial Load

Besides load torque, acceleration torque, speed, and load inertia, overlooking certain sizing parameters during the motor sizing process can literally make or break your machine.

Topics: AC Motors, Stepper Motors, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Servo Motors, Motion Control Basics

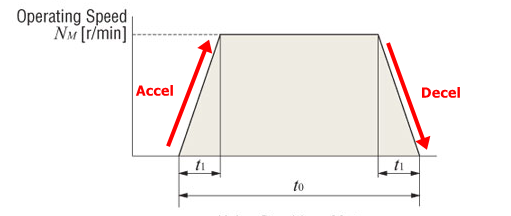

Motor Sizing Basics Part 3: How to Calculate Speed, Acceleration Torque, and RMS Torque

Now that we understand the calculations behind load torque and load inertia, we're a little closer to motor selection. You might be wondering why I separated load torque and acceleration torque calculations. That's because in order to calculate for acceleration torque, load inertia and speed must be calculated first.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Motion Control Basics

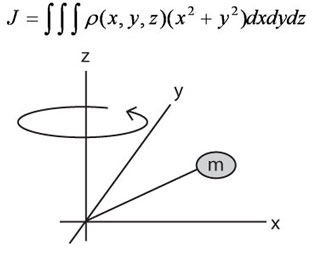

Motor Sizing Basics Part 2: How to Calculate Load Inertia

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics

Motor Sizing Basics Part 1: How to Calculate Load Torque

Proper sizing of a motor requires that 3 criteria must be met: torque, load inertia, and speed. For the first part of this Motor Sizing Basics series, I will be explaining what load torque is, how to calculate it for specific application examples, and how it fits into the torque requirement for the application.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics, Conveyors

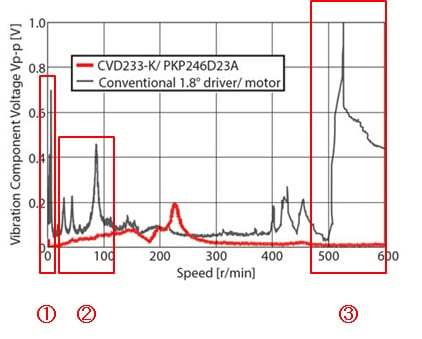

Stepper motors vibrate. It's what they do. To minimize motor vibration, first we need to understand where they come from.

Topics: Stepper Motors, Smooth Drive, Motor Sizing, VIDEOS, Gearheads