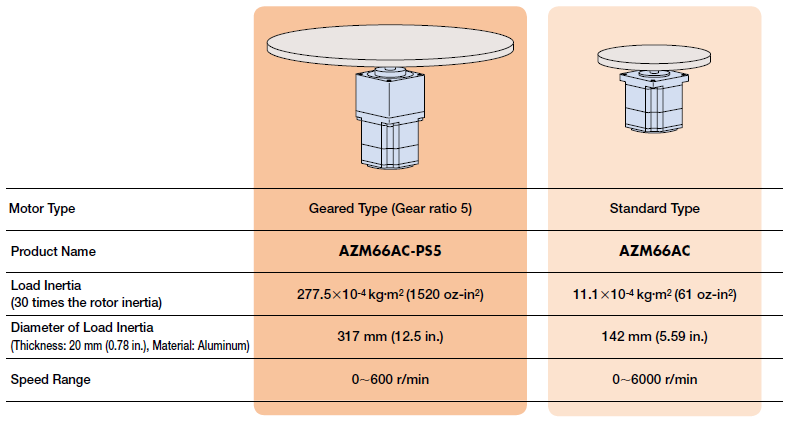

By adding a gearhead to a motor, a motor becomes a gear motor, and its torque is multiplied by its gear ratio and gear efficiency. However, beyond increasing torque, there are many other advantages to using gear motors.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Topics: AC Motors, Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, BLDC Motors, Gearheads, Application Examples, Rotary Actuators/Index Tables

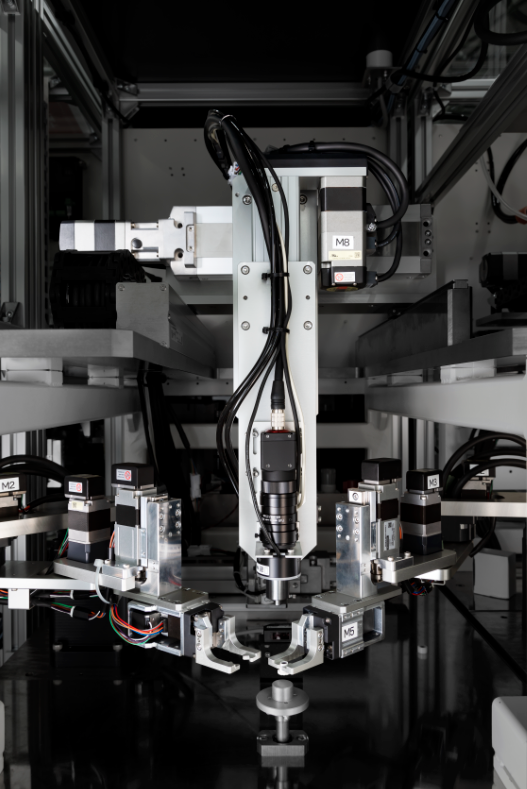

Optimal Motors for Chemical Mechanical Polishing of Wafers

Oriental Motor provides a wide variety of products to meet semiconductor equipment design goals. This post focuses on motor selection for two specific motion axes of a semiconductor manufacturing process called CMP (Chemical Mechanical Polishing) and explains how to save time by using different products from the same family.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Gearheads, Application Examples, Rotary Actuators/Index Tables, Chemical Mechanical Polishing, Semiconductors

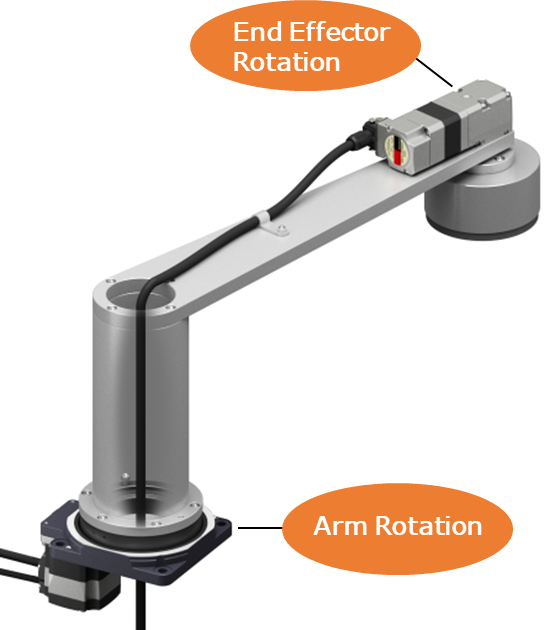

How to Build a SCARA Robot with Off-The-Shelf Products

Robotics automation can be easier to build than you think. Here's an example of how a 5-axis SCARA robot can be built in-house with off-the-shelf products.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Motor Sizing, VIDEOS, Software, Network, Application Examples, Rotary Actuators/Index Tables

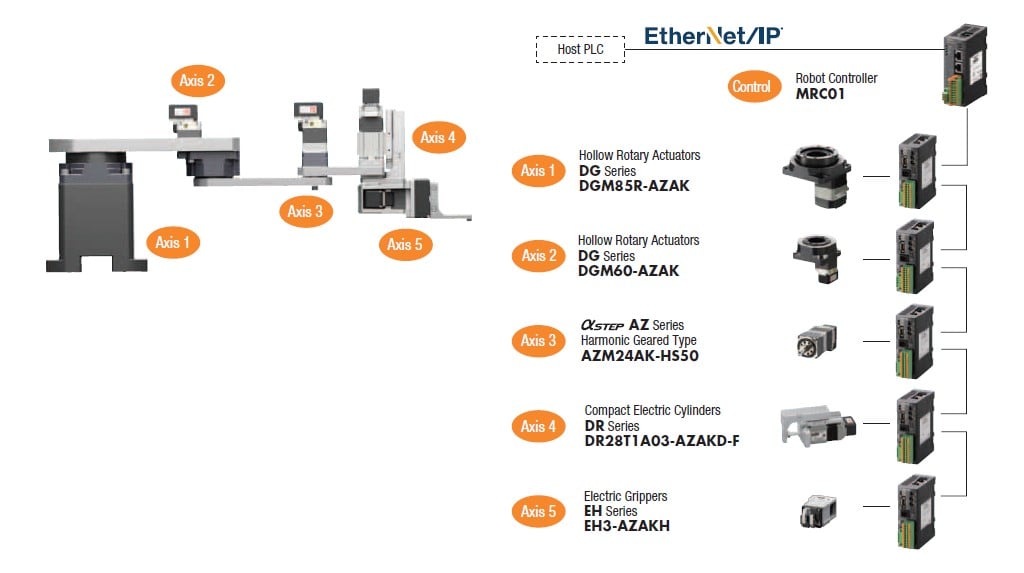

Case Study: SCARA and Cartesian/Gantry Robots for Automated Assembly

In this post, we introduce a real-world SCARA and cartesian/gantry robot example of in-house automation built using our AlphaStep AZ Series family of motors, actuators, drivers, and our 4-axis robot controller.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Software, Rotary Actuators/Index Tables, XYZ/Cartesian/Gantry, Case Studies

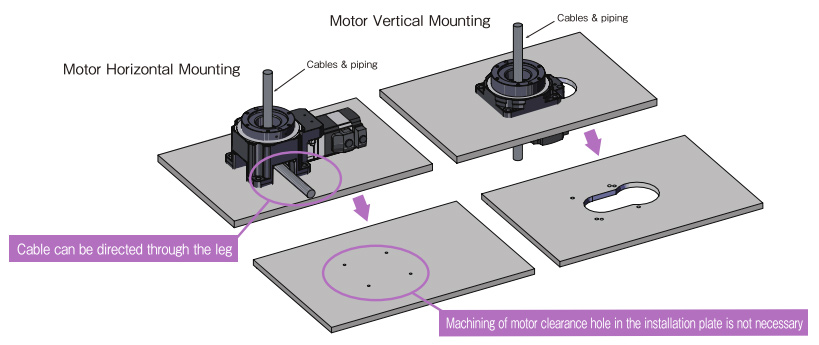

Flexible Configurations For Hollow Rotary Actuators

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Gearheads, Rotary Actuators/Index Tables

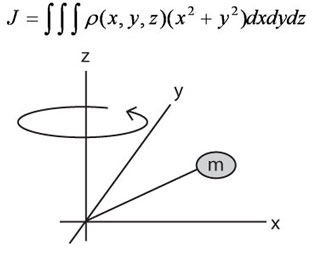

Motor Sizing Basics Part 2: How to Calculate Load Inertia

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics

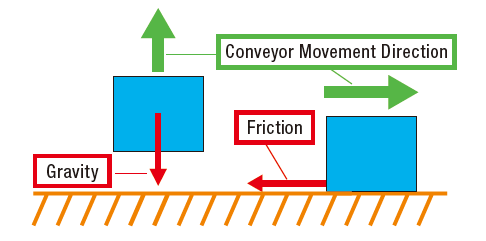

Motor Sizing Basics Part 1: How to Calculate Load Torque

Proper sizing of a motor requires that 3 criteria must be met: torque, load inertia, and speed. For the first part of this Motor Sizing Basics series, I will be explaining what load torque is, how to calculate it for specific application examples, and how it fits into the torque requirement for the application.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics, Conveyors