At Oriental Motor, continuous improvements are part of our process. This article takes a deep look at functional updates of our popular BLH Series drivers, how they differentiate from existing drivers, and how they can improve functionality and performance.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Improve BLDC Motor Performance With Updated Drivers

Topics: Torque Limit (Push Motion, Tension Control), Robotics, Speed Control, VIDEOS, BLDC Motors, Software, Bottle Capping, AGV/AMR

Head-to-Head: 1 HP BLDC Motor vs 1 HP AC Induction Motor

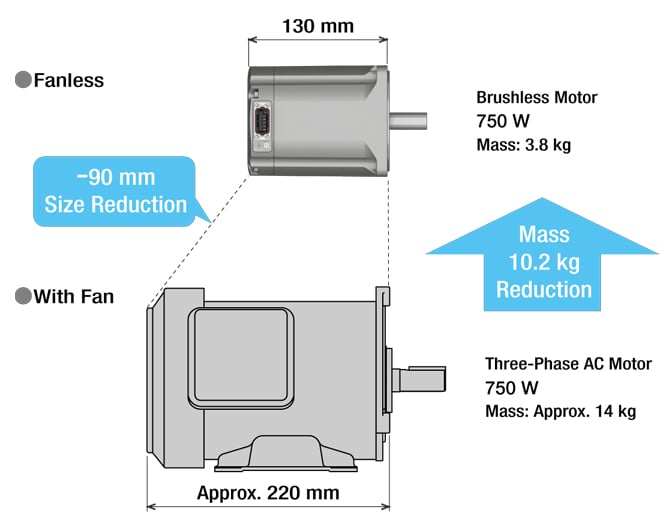

For machine designers who typically specify 3-phase AC induction motors and VFDs to meet variable speed requirements, brushless DC (BLDC) motors can be a cheat code to designing smaller, lighter, and more efficient machines. This article compares our 750 W (1 HP) Brushless DC Motor to an equivalent AC motor in efficiency, size/weight, and performance.

Topics: AC Motors, Speed Control, BLDC Motors, Application Examples, New Product Introductions

Advancing Conveyor Design and Performance with Brushless DC Motors

AC induction motors are the workhorses that power many types of conveyors to transport materials. However, there's a smaller but mightier type of motor that can help enhance the design and performance of conveyors for many industries.

Topics: Speed Control, VIDEOS, BLDC Motors, Washdown, Application Examples, New Product Introductions, Food & Packaging, Grip Conveyors, Conveyors

Explainer: How to Synchronize Speeds Between Multiple Motors with One Potentiometer

For speed synchronization applications like a dual belt labeling conveyor, multiple motors must run at the same speed. What is the best type of motor to use and what are the methods to achieve this? Our application engineer set up a product demonstration to show you how this can be done with one potentiometer.

Topics: Speed Control, VIDEOS, BLDC Motors, Grip Conveyors, Conveyors, Product Demos

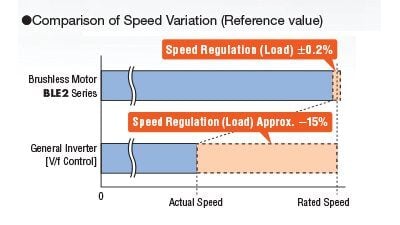

VFD vs BLDC: Which Technology is Better for Speed Control?

While AC induction motors and VFDs are often the go-to choice for speed control applications, several other alternatives are available, from servo motors to AC motors with tachometers. However, brushless (BLDC) motor technology is quickly growing in popularity in compact designs while also offering other advantages that are often overlooked.

Topics: AC Motors, Speed Control, BLDC Motors

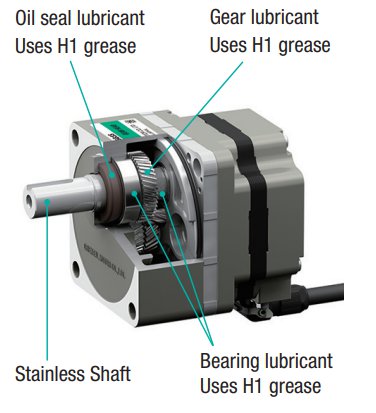

Gearhead Selection for Brushless Motors

Gearheads play a crucial role in motor performance optimization. Each type of gear offers its own features and characteristics, and the gear ratio alters a motor's output torque and speed. By carefully selecting the optimal gear type and ratio, engineers can fine-tune motor performance to align precisely with the application requirements.

Topics: Speed Control, Motor Sizing, BLDC Motors, Gearheads, Motion Control Basics

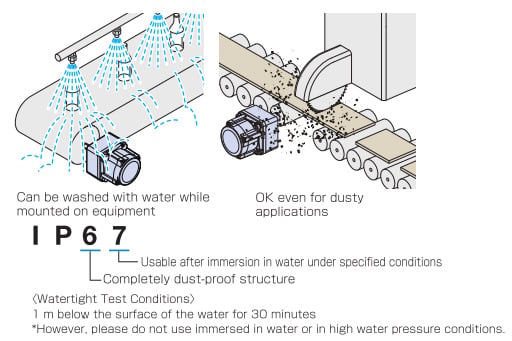

What Does Ingress Protection Really Mean for Electric Motors?

Electric motors drive our world, but they can be susceptible to environmental hazards like dust or water. This article explores IP ratings and codes, what they are, how they're tested, and why they're critical for motor durability and reliable performance.

Topics: AC Motors, Speed Control, VIDEOS, BLDC Motors, Washdown, Application Examples, Motion Control Basics, Conveyors

In today's fast-paced industrial landscape, the role of conveyors has become more crucial than ever. These systems efficiently move materials, products, and goods for numerous industries, from labeling and packaging to warehousing and distribution. While many types of motors can be used in conveyors, this article highlights a few reasons why brushless motors should be a primary choice for conveyor applications.

Topics: Speed Control, VIDEOS, BLDC Motors, Application Examples, Food & Packaging, Semiconductors, Conveyors

Peristaltic Pump Motor Selection Tips: Brushless Motor or Stepper Motor?

This article highlights the advantages of brushless motors and stepper motors for driving a peristaltic pump, which is among the most common motor applications in medical, pharmaceutical, biotech, and diagnostic equipment.

Topics: Stepper Motors, Speed Control, BLDC Motors, Pumps, Application Examples, Medical

Motors exhibit noise. The important thing to know is how you distinguish normal noise from abnormal noise, and how to troubleshoot.

Topics: AC Motors, Stepper Motors, Speed Control, Gearheads, Troubleshooting

.jpg)