Electric motors drive our world, but they can be susceptible to environmental hazards like dust or water. This article explores IP ratings and codes, what they are, how they're tested, and why they're critical for motor durability and reliable performance.

What is an IP Rating, and Why is It Important?

Water or moisture can cause electrical shorts in the motor windings or connections, which can cause motor failures, electric shock, or fire. Dust or other pollutants can also cause motors to overheat and fail. When these motors are running conveyors in a factory production line, a motor failure can cause an interruption. If you don't have a replacement motor in stock, that could mean days of lost production.

Electric motors needed a standard rating system to prove that they can reliably operate in specific environments. Therefore, an IP (Ingress Protection) rating system was developed in 1976 by the IEC (International Electrotechnical Commission) to classify the level of protection a product provides against water particles, dust, and other solid objects under the international standard IEC 60529. The European equivalent standard is EN 60529, which was introduced in 1934 in Germany and used by the European Union by the European Committee for Electrotechnical Standardization.

Better water or dust protection typically requires improvements in motor casing design using o-ring seals, different materials, and special connectors. We'll cover these after we cover the IP code definitions.

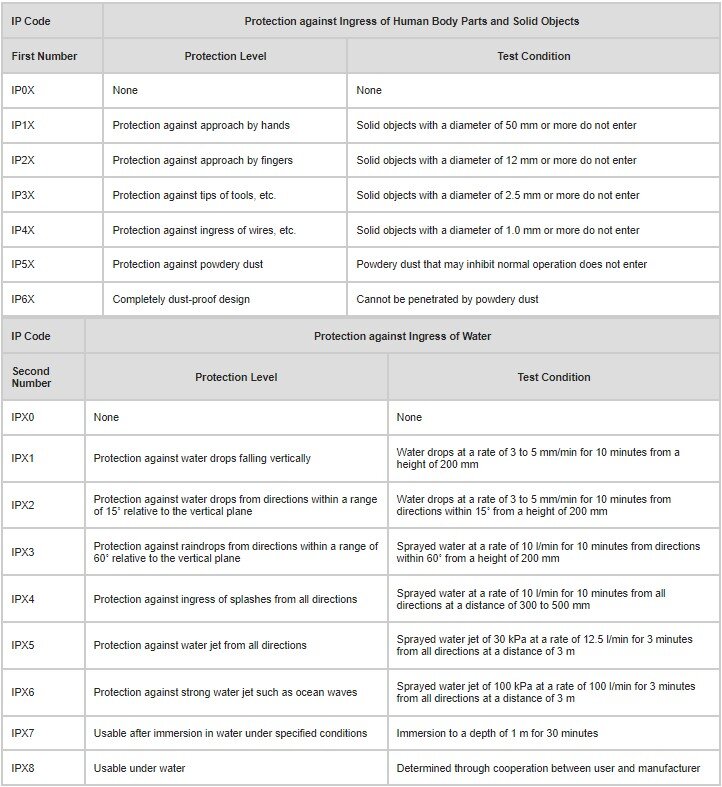

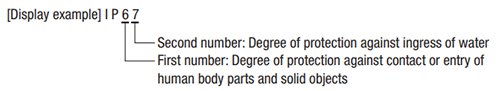

What Do the IP Codes Mean?

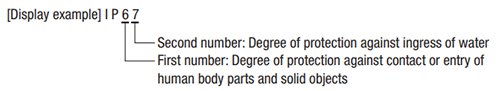

Different levels of protection are offered for different needs and budgets. Various levels of protection are classified by IP codes. Each code has two numbers. The first number defines the level of protection and test condition for various solid objects, from human hands to dust. The second number defines the level of protection against water particles, from water drops to immersion in water. Whether you're an electrical engineer, a maintenance professional, or a hobbyist, knowing

what these codes mean can help you make informed decisions.

IP Codes Defined

Here's what each number really means in an IP code.

A newer IP69 rating under

IEC 60529 – Degrees of protection provided by enclosures (IP code) was introduced in 1993 for equipment installed in areas that are washed by high pressure and steam water jets, such as in pharmaceutical manufacturing or food packaging. Another IP69K rating was added by

ISO 20653 – Road vehicles – Degress of protection (IP code) – Protection of electrical equipment against foreign objects, water and access, which was originally for equipment installed on road vehicles but has branched out to food processing and agriculture. Here are the

differences between IP69 and IP69K, which can be confusing (thanks F2 Labs).

How are Tests Performed?

Although ingress protection is a self-certification, manufacturers or 3rd party testing facilities have to adhere to the code definitions and testing standards. The water spray test is part of the overall testing we perform on our products to adhere to the highest quality. Our water spray tests also include a heat shock test and a vibration test.

Here's a video of various ingress protection tests.

- ① Heat shock test

-

Seal parts (O-rings) undergo accelerated heat deterioration equivalent to 5 years. (IEC 60068-2-14)

- Preset temperature

- ✅ Low temperature -24℃, high temperature 100℃

- Standing time

- ✅ Low temperature 85 minutes, high temperature 75 minutes

- Number of cycles

- ✅ 110 cycles

- ② Vibration test

-

Apply vibration under the following conditions. (IEC 60068-2-6 Annex C)

| ✅ Frequency range |

: |

10~150Hz・10~60Hz |

: |

Both amplitudes 0.7mm |

| ・60~150Hz |

: |

Acceleration 50m/s 2 |

| ✅ Vibration direction |

: |

3 directions (X, Y, Z) |

| ✅ Number of sweep cycles |

: |

20 times in each direction |

- ③ Water spray test

A water spray test with a water pressure of 100kPa and a flow rate of 100L/min is performed on the area where seal parts are present.

- Judgment criteria

- ✅ Make sure that no water has entered the motor.

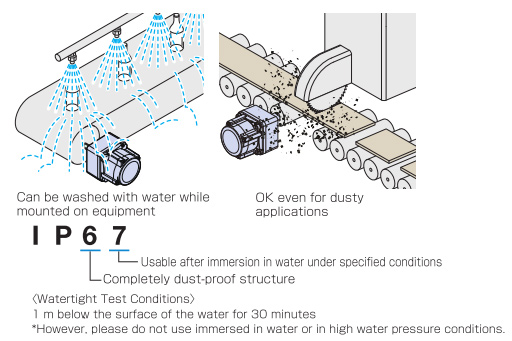

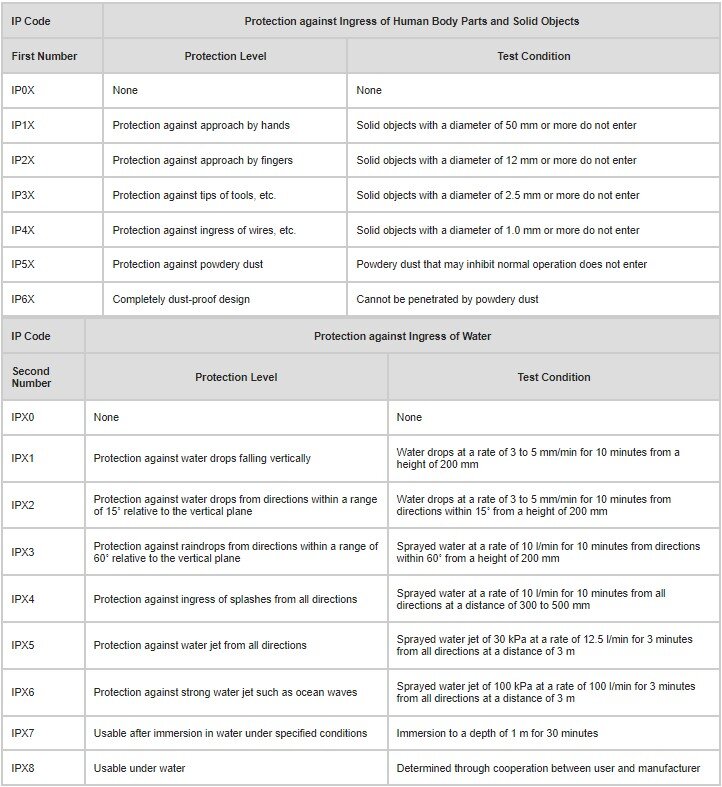

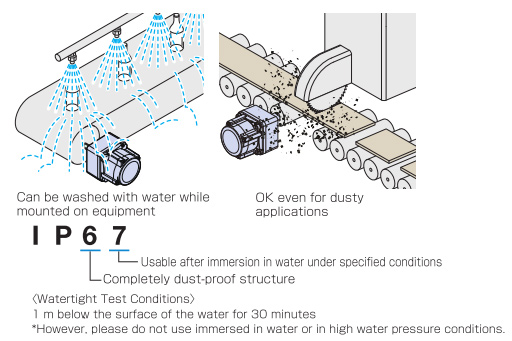

Now let's take a look at some examples of IP67 motors.

Exhibit A: IP67 Rated AC Gearmotors

Our FPW Series IP67 rated AC gearmotors are ideal for general purpose washdown applications. They are dust-proof and can protect against jets of water. An induction motor and a gearhead are encapsulated together and coated with special anti-corrosive epoxy paint. The motor's vaccum cast so no air bubbles can be formed, the gearbox has a watertight seal, and the stainless steel shaft also offers oil-shield protection.

The FPW Series lineup includes 25 W, 40 W, 60 W, and 90 W single-phase and three-phase gearmotors with gear ratios from 3:1 to 180:1. Variable speed control can be achieved by VFDs, and only 3 wires are required for operation. They are recognized by UL and CSA and certified under the China Compulsory Certification System (CCC System). CE Marking is used in accordance with Low Voltage Directive. Additionally, our wide range of products includes those that meet the power supply voltages of major countries in Asia, North America, and Europe.

Application Examples

| IP67 rated AC gearmotor in a washdown conveyor |

IP67 AC gearmotor with VFD on a potato cleaning conveyor |

|

|

|

Exhibit B: IP67 Rated Brushless Gearmotors

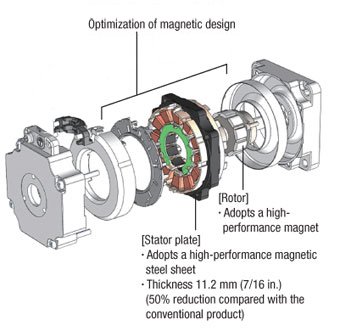

Our newest brushless motors feature a high-performance magnet and an optimized slim design with high-performance magnetic steel laminations, which shortens the stator to just 11.2 mm—about half the thickness of a traditional brushless motor. The efficiency of brushless motors also allows us to adopt a fan-less casing structure, which shortens the motor length even more. Compared to an AC motor, a 200 W (1/2 HP) brushless motor can be 83 mm shorter and 3.3 kg lighter.

Similar to VFD-controlled AC motors, these brushless motors are ideal for advanced speed control applications where multiple speed, acceleration, and deceleration profiles are necessary. However, brushless motors are a step above with efficiency, closed-loop speed regulation, and a wider speed range.

These new slim brushless motors are paired with two different drivers; each with a different set of features. This means you can choose either the

BMU Series to combine the motor with a

basic driver or choose the

BLE2 Series for an

advanced driver. IP ratings are available in IP65, IP66, and IP67. Output wattages are available for 30 W, 60 W, 120 W, 200 W, 300 W, and 400 W, and gear ratios from 5:1 to 1200:1 in various types like parallel shaft, hollow shaft, and right-angle shaft types.

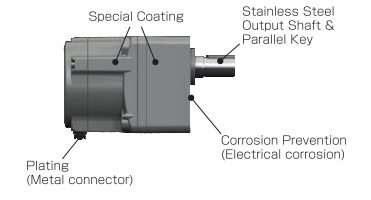

On the IP67 rated version of the motor (200 W/300 W/400 W only at this time), we have improved the casing structure and added O-rings to improve seal performance, added a special anti-corrosive coating, standardized on a stainless steel output shaft (and parallel key/screws), added rust prevention measures, and adopted a metal lever for the motor connector. The connectors go through tensile fracture strength tests in multiple directions. These motors also go through vigorous water spray tests; including salt water spray. Lastly, we have also switched over to a one cable design where no relay boxes are required to extend the cable to the driver.

Product Videos

| IP66 Connector |

IP66 vs IP67 Motor Comparison |

|

|

|

The Highest Rating Doesn't Always Mean the Best Choice

Choosing the right IP rating for your motor is not a one-size-fits-all decision. It depends on the specific environment and conditions in which the motor will operate. For instance, a motor used in a dusty factory will need a different IP rating than a motor that needs to be washed down periodically, and stainless steel motors work best for caustic washdown environments.

Make sure you select the right IP rating for your motor (and your budget). We're here if you need help.

- Factors to Consider Beyond IP Ratings

While IP ratings are important, they're not the only factor to consider. Power, efficiency, size, and application-specific requirements also play a crucial role. Make sure you select a motor that meets all of your application requirements.

- Regular Maintenance and Inspection

Regular maintenance and inspections are key to maintaining the ingress protection level of electric motors. This includes tasks like proper installation, gasket replacement, and checking for any signs of damage. Ingress protection can degrade over time.

Some of the application examples for IP67 motor are a washdown belt conveyor and a sawing roller conveyor.

When to Consult with Specialists

If you're unsure about the necessary IP rating for a specific motor application, it's best to consult with a specialist. Our knowledgeable technical support team can provide expert advice and help you make an informed decision, ensuring the longevity and efficiency of your motor.