At Oriental Motor, continuous improvements are part of our process. This article takes a deep look at functional updates of our popular BLH Series drivers, how they differentiate from existing drivers, and how they can improve functionality and performance.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Improve BLDC Motor Performance With Updated Drivers

Topics: Torque Limit (Push Motion, Tension Control), Robotics, Speed Control, VIDEOS, BLDC Motors, Software, Bottle Capping, AGV/AMR

Tension control is a niche application that is not easy to implement. Using the right type of motor is the first step to success. Hint: you don't always have to use a servo motor.

Topics: AC Motors, Torque Limit (Push Motion, Tension Control)

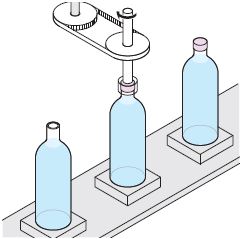

Torque Limit Application Example - Bottle Capping with BLDC Motors

For applications where torque needs to be limited, an external mechanical torque limiter is typically required in addition to the motor system. When the torque exceeds the limit, the torque limiter will either decouple the load or limit the torque by slipping. An electric motor system's built-in torque limit function can simplify machine designs by eliminating this extra component.

Topics: Torque Limit (Push Motion, Tension Control), Speed Control, VIDEOS, BLDC Motors, Application Examples, Food & Packaging, Bottle Capping

Improve Gripping Operation with Multiple Torque Limit Settings

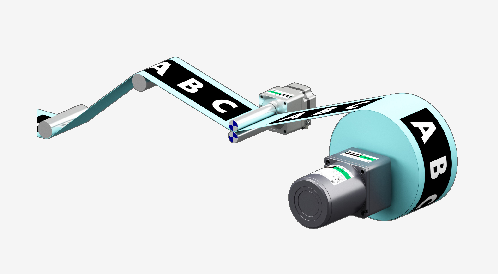

Robotic grippers are typically used to grip parts for transport. The driving force behind a gripper can be pneumatic, hydraulic, or electric. Which type is best for gripping?

Topics: Torque Limit (Push Motion, Tension Control), Robotics, Speed Control, VIDEOS, BLDC Motors, Application Examples, Medical, Grip Conveyors

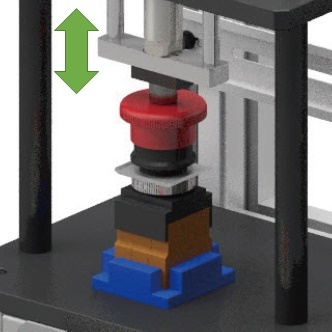

Smart System Performs Reciprocating Motion & Force Sensing Without a PLC or External Sensors

Automation is great for repetitive tasks, such as test fixtures for a process that has to repeated. In this post, we will explain how to perform a reciprocating motion (back and forth cycles) with a product that does not require a PLC or external presence sensors, which can help speed up design cycles.

Topics: Torque Limit (Push Motion, Tension Control), Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples