Automation is great for repetitive tasks, such as test fixtures for a process that has to repeated. In this post, we will explain how to perform a reciprocating motion (back and forth cycles) with a product that does not require a PLC or external presence sensors, which can help speed up design cycles.

|

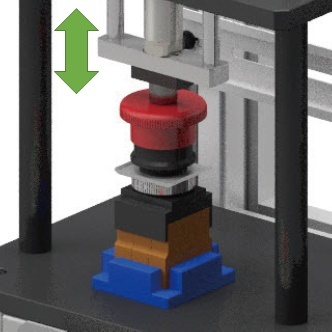

We will use an endurance testing application example where a test fixture is to test a push button repeatedly for 10,000 cycles. To perform the test, the red button needs to be pressed 10,000 times. An actuator will need to move up and down repeatedly in order to provide the pressing motion. An external pressure sensor or presence sensor would be required to provide a signal to tell the actuator when to stop pressing and move back up to a home position. Typically, a PLC is also required to manage these I/O signals. This means more parts, knowledge, and labor are necessary for a successful implementation. |

| Challenge | Create Reciprocating Motion and Torque Sensing Without a PLC or Sensors |

Conventional Equipment: Endurance test equipment that receives inputs from an external sensor with a host PLC and presses the push button 10,000 times.

Problems with Conventional Equipment:

- Many components need to be integrated including motor, actuator, driver, sensors, and PLC.

- An external host controller (PLC) is required, which drives up the cost.

- External sensor(s) are required for limits and force sensing.

- More knowledge, inventory, and labor are necessary to integrate the entire system successfully.

There may be an easier way.

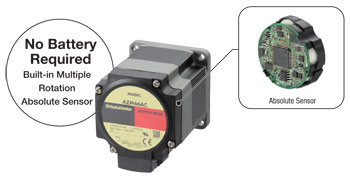

| Solution | EAC Series Motorized Cylinder and Stored Data Driver System |

For such a repetitive push and pull application, an electric linear cylinder system is recommended to perform the linear motion. With built-in stored data operations from a stored data type driver, such as automatic sequential operation, some PLCs, or at least some PLC functions, can be eliminated.

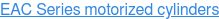

Oriental Motor's  offer the same

offer the same  as well as a built-in absolute encoder from the popular

as well as a built-in absolute encoder from the popular  . Along with its dedicated driver, the entire system is plug and play, and specifications are guaranteed. The AlphaStep hybrid control technology automatically switches between open-loop and closed-loop operation to provide error-free position control, while the built-in mechanical absolute encoder (ABZO sensor) manages absolute position coordinates without the need for a backup battery. The EAC Series linear cylinders are also offered with an optional, pre-assembled linear guide to handle moment loads, which eliminates the need for an external guide. Due to pre-assembled components, guaranteed specifications, and built-in functions, engineers can focus their available time on improving other areas of their design.

. Along with its dedicated driver, the entire system is plug and play, and specifications are guaranteed. The AlphaStep hybrid control technology automatically switches between open-loop and closed-loop operation to provide error-free position control, while the built-in mechanical absolute encoder (ABZO sensor) manages absolute position coordinates without the need for a backup battery. The EAC Series linear cylinders are also offered with an optional, pre-assembled linear guide to handle moment loads, which eliminates the need for an external guide. Due to pre-assembled components, guaranteed specifications, and built-in functions, engineers can focus their available time on improving other areas of their design.

The role of the PLC in this example is to send command signals to the driver in order to tell the actuator when and how far to move up and down. With advanced point-to-point programming from the  , a continuously repeating (looping) motion can be programmed without a PLC. This is called Automatic Sequential Operation.

, a continuously repeating (looping) motion can be programmed without a PLC. This is called Automatic Sequential Operation.

Additionally, the driver's push motion function can be used in place of pressure or torque sensors. For example, if you set the push motion at 20%, a dedicated TLC output signal can be used to indicate when that 20% torque has been reached, and the actuator can be programmed to move back up to its home position when it happens. Essentially, a system can be configured where the actuator comes down and presses the button, then when the actuator senses a 20% load torque from pressing the button, it will automatically move back up to the home position, then repeat. Additional programming can be added to start the operation when the actuator completes a homing operation, or when the system provides a READY status. Any of the physical or remote I/O signals can be used to start a specific sequence of motion (see Event Trigger function).

To set up the motion data and system parameters, or to monitor the statuses of the EAC Series, please  our powerful MEXE02 universal product support software.

our powerful MEXE02 universal product support software.

|

Advantages Offered by EAC Series:

|

| Result | Simpler Designs, Lower Costs, and Faster To Market |

See how easy it is to program the data for the reciprocating motion with the MEXE02 software.

Watch more  , such as push motion setting or palletizing operation.

, such as push motion setting or palletizing operation.