Tension control is a niche application that is not easy to implement. Using the right type of motor is the first step to success. Hint: you don't always have to use a servo motor.

Some applications require a motor to be able to control or limit its torque. To wind or unwind an elastic material like film without breaking it, the motor must vary its output torque based on the film roll diameter to keep the tension the same. To stamp labels on eggs or to tighten a screw, the motor's output torque must be limited to avoid breaking the egg shell or striping the threads.

Brushless motors, stepper motors, and servo motors are all capable of controlling and limiting their output torque. Since tension control is a bit more complicated, dedicated servo motor drivers that can automatically calculate and adjust torque based on a changing diameter are used. However, if you don't need all the bells and whistles, there is another low-cost alternative that should be considered.

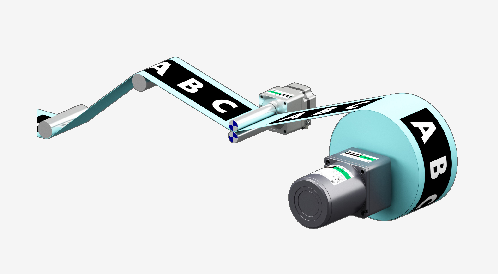

This application image shows how two motors work in tandem in order to maintain the tension force and feed a material.

The smaller brushless motor in the center is winding, and the bigger torque motor is being back-driven by the brushless motor and providing a specific tension force.

What are Torque Motors?

Torque motors look just like regular induction motors, but they're not.

Torque motors are designed to vary their torque by increasing or decreasing their input voltage. They can also be stalled (or even back-driven) continuously without overheating, which is a "must-have" motor characteristic for tension control.

Compared to an induction motor, a torque motor differs in its design by using a balanced winding and a high-slip rotor instead of a low-slip rotor. The high-slip rotor used by a torque motor is made from a solid piece of metal and has no current carrying aluminum bars.

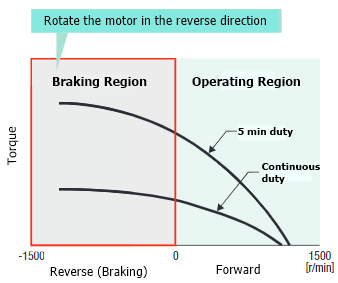

Due to this high-slip rotor design, a torque motor can be operated as a brake to provide brake torque when back-driven. Although the motor size only goes up to 20 W, a variety of gear ratios are available to increase the torque. Single-phase 110/115 and 220/230 VAC versions are available.

How Torque Motors Control Torque

|

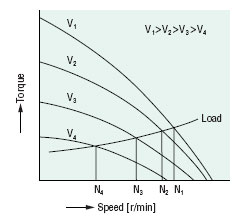

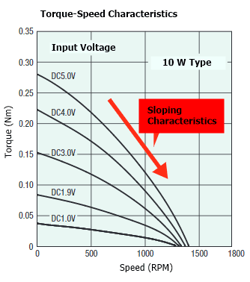

For a torque motor, the input voltage and load determine the output torque and speed. A torque motor reaches full torque at zero speed and is rarely used at full speed.

The location where the "load" line intersects the voltage line is the expected motor performance. |

For example, for the given load, if voltage V4 is applied to the motor, the motor will limit its output torque where the "V4" line intersects the "Load" line, and the motor will run at "N4" speed.

| Torque Motor Benefit #1: | Simple Configuration |

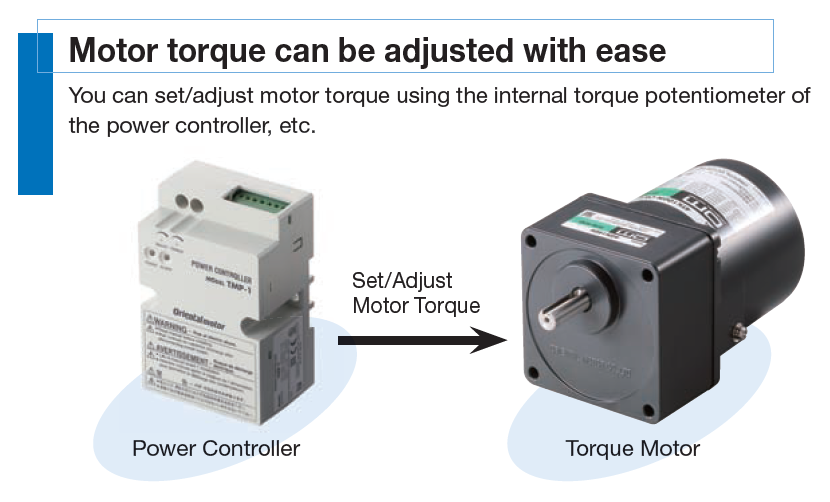

Unlike a servo motor tension control system, a torque motor does not need motor feedback or additional sensors to control its torque. You just need a device to vary the input voltage to the motor, like the TMP-1 power controller.

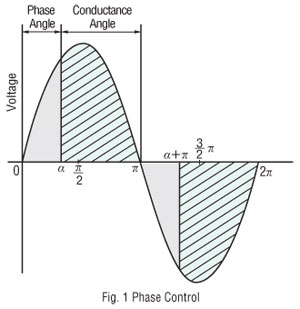

The TMP-1 power controller uses the triac phase control method to vary its voltage to the torque motor. You can also use anything that can output a consistent voltage to the motor, such as a PLC with an analog output card.

|

|

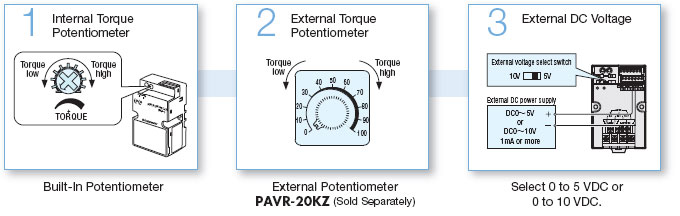

3 ways to control voltage/torque:

The torque motor can also operate on DC voltage.

|

When supplying DC voltage: Instead of rotating, the motor will provide braking torque and act to provide brake tension. The braking torque can be varied with voltage. |

| Torque Motor Benefit #2: | Avoids Slack |

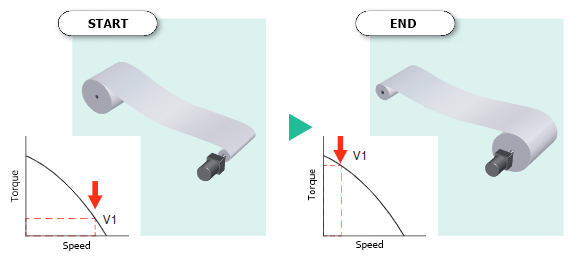

Tension is necessary to avoid "slack" in the material being wound or unwound. However, for the tension and speed to stay the same in a winding application, the torque and speed need to change continuously.

|

|

| When the diameter of the roll is smaller, the torque of the motor can be lower, but it needs to rotate faster. | When the roll diameter is large, the motor will need more torque, but it can rotate slower. |

| Torque Motor Benefit #3 | Maintain proper tension with fine adjustment |

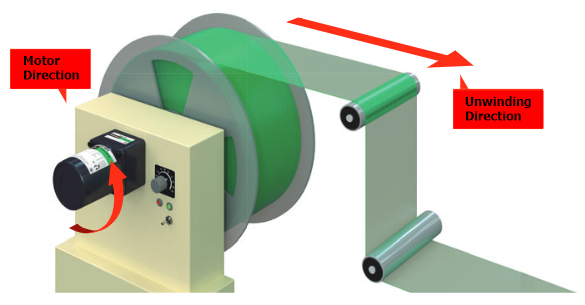

The torque motor can be used as an unwinding brake. A torque motor can obtain a braking force when it is rotated in the opposite direction to the rotation direction of the motor by an external force, such as another motor.

By using a torque motor on the unwinding side of the work, winding can be achieved while maintaining appropriate tension. It also does not wear out, so no brake maintenance is required.

Rotate the motor in the opposite direction to the winding direction

|

|

| FYI | Torque Motor Tips to Remember |

|

⚠️ A torque motor will heat up quickly if operated at 115 VAC. Therefore, a 5-minute duty cycle is recommended. For continuous duty cycle, please use at 60 VAC or below. ⚠️ When winding with constant tension, keep in mind that the diameters are always changing. Therefore, to maintain the tension and feed rate, the voltage needs to change along with it. ⚠️ For proper tension control, you need two motors. One motor needs to be a bigger motor since it needs to pull material and overcome the tension. The other motor is typically small since it only needs sufficient torque to provide the tension. One motor is always "over-torquing" the other motor. |

|

Here are some applications that the torque motor can be used for:

|

|

Last but not least, here's a video demonstration of the torque motor.

A torque motor sits on the left, and a speed control motor sits on the right. A rope and pulley are mounted to each motor shaft to demonstrate the effect of tension. As the rope extends and retracts on the left side, you can see that the rope stays tight with tension. As the rope extends and retracts on the right side, you can see how the slack builds up on the rope.

|

|

Ready to learn how to size a torque motor?

If you need a more advanced product than the simple operation offered by torque motors, here are some options.

| AC Motors Torque Motors |

Brushless Motors |

AlphaStep AR/AZ Series |

Servo Motors NX Series |

|

|

Motor |

|

|

|

|

| Torque Control Accuracy | ±10% | ±10% |

AR: ±10% AZ: ±20% |

±5% |

| Total Cost | Low | Moderate |

Moderate |

High |

You can expect much better "repeatability" when you use the same motor, with the same driver, with the same load, and with the same setting. For example, the repeatability for NX Series is ±0.23% (reference value).

The right motor for tension control depends on how accurately you need to control the output torque

(and how much you want to spend.)