For applications where torque needs to be limited, an external mechanical torque limiter is typically required in addition to the motor system. When the torque exceeds the limit, the torque limiter will either decouple the load or limit the torque by slipping. An electric motor system's built-in torque limit function can simplify machine designs by eliminating this extra component.

Challenge Design a simple and affordable bottle capper without an external torque limiter

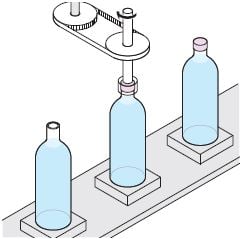

Conventional Capping Machine

Conventional Capping Machine

To prevent damage to caps caused by excessive torque, a conventional capping machine tightens the bottle caps to an appropriate torque level by using an external torque limiter or magnetic clutch device.

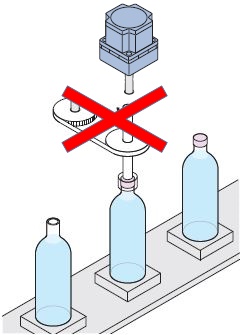

Problems with Conventional Capping

The torque limiter or magnetic clutch and other external components are required. This makes the machine more complicated and expensive.

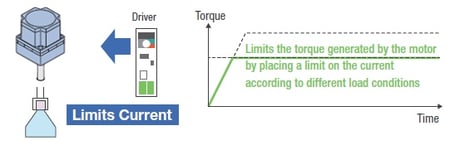

Solution Use the torque limit function of a brushless motor system to eliminate the torque limiter

Several of Oriental Motor's brushless motor systems feature a built-in electrical torque limit function. This function allows the user to set a certain torque limit by a % of the rated torque, and it will regulate the torque at that level. This function is designed for processes such as capping, pressing, or stamping.

For example, use a BLE2 Series brushless motor and driver system to eliminate the external torque limiter. Since no external parts are required, the equipment design can be simplified, and the cost can be reduced.

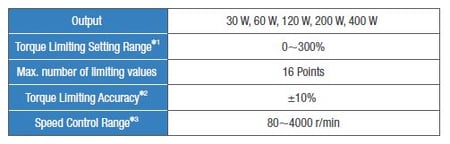

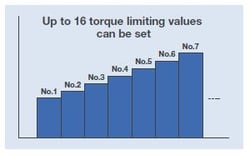

With the torque limit function, the motor system can be set up to generate a torque that does not exceed the set value as a % of the rated torque. With the BLE2 Series, up to 16 different torque limit settings can be stored. Other systems, such as the AZ Series stepper motors, can store up to 256 different settings.

With the torque limit function, the motor system can be set up to generate a torque that does not exceed the set value as a % of the rated torque. With the BLE2 Series, up to 16 different torque limit settings can be stored. Other systems, such as the AZ Series stepper motors, can store up to 256 different settings.

How Does It Work?

A driver monitors feedback from the motor and regulates current and speed based on operating conditions. Since current is proportional to torque, torque is also controlled. Setting a torque limit basically limits the motor current. However, the motor will keep rotating at the set torque limit even when it is stalling, and the motor can be back-driven without issues.

✽1: The value for the rated torque is 100%.

✽2: An error up to a max. of approximately ±10% (at rated torque and rated speed) may occur between the setting value and generated torque due to the setting speed, power supply voltage,

or motor cable extension length.

✽3: The BX II Series with a speed control range of 2∼4000 r/min is also available.

Watch this video to see how feedback control, alarm output and torque limits works with a BLE2 Series motor and driver. Stored operation data can be changed by the front panel buttons of the driver, or by the MEXE02 support software.

|

|