This article highlights the advantages of brushless motors and stepper motors for driving a peristaltic pump, which is among the most common motor applications in medical, pharmaceutical, biotech, and diagnostic equipment.

|

Jump to section: |

What is a peristaltic pump?

A peristaltic pump (sometimes called a "roller pump") is used for moving a variety of fluids by waves of contraction produced mechanically on flexible tubing. The flexible tubing is typically arranged radially around the motor, which drives the wheels to squeeze and push the liquid through the flexible tubing. These pumps are typically used to pump clean/sterile or highly reactive fluids without exposure to contamination, such as IV fluids, chemicals, or slurries. Peristaltic pumps are a part of many common medical equipments, such as blood analyzers, and they are easier to maintain, more versatile, and more energy-efficient than traditional centrifugal pumps. The only component that needs to be replaced periodically is the flexible tubing. The peristaltic pump was first patented in the United States in 1855.

Peristaltic pump with LCD screen

How does a peristaltic pump work?

In the example below, two wheels are mounted to the motor shaft. As the motor rotates, the wheels push a specific amount of liquid through the flexible tubing. This process is called peristalsis and is actually the same method used in our gastrointestinal tract. As the motor spins faster or slower, the flow rate increases or decreases.

| Peristaltic pump internal structure with two sprung rollers | Peristaltic pump rollers in motion |

|

|

Here's what might affect the flow rate:

- Tube inner diameter – larger inner diameter = higher flow rate

- Pump-head outer diameter – larger outer diameter = higher flow rate

- Pump-head rotational speed – higher speed = higher flow rate

- Inlet pulsation – the pulse reduces the filling volume of the hose.

The motor's precision in responding to commands makes a difference in the accuracy of the flow rate, so the motor you select for the pump will make a difference in its output.

The two most popular types of motors for peristaltic pumps are

Let us introduce our two most popular types of motors for peristaltic pumps. We also asked our customers why they selected the motor.

| Stepper motors for precision in flow rate |

- The precise positioning capability of stepper motors makes them ideal for fine flow adjustments.

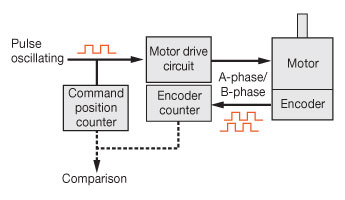

- Many types are available. Our customers like the preassembled encoder option for quality and convenience.

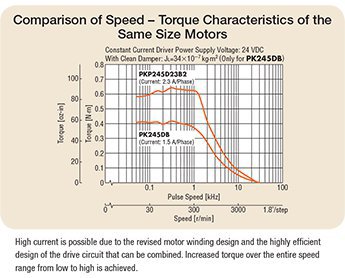

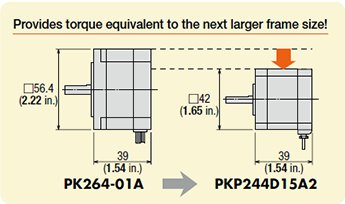

- Due to tubing friction, peristaltic pumps require high starting torque. Stepper motors naturally offer high torque at low speeds, but high torque type stepper motors like the PKP Series can allow for downsizing.

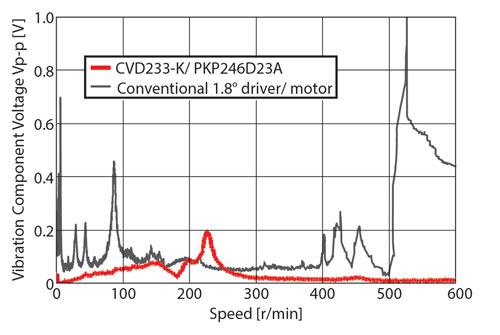

The PKP Series 1.8°/0.9° stepper motors generate high torque due to continuous design improvements in technologies, such as air gap, magnetic rotor/stator design, and high winding density. A variety of frame sizes are available from NEMA 8 (0.79"/20mm) to NEMA 34 (3.35"/85mm). Standard, high-resolution, geared (spur/planetary/harmonic), encoder (TTL/line driver), and electromagnetic brake options are available. For improved performance, we recommend using our CVD drivers since the drivers were designed specifically for PKP Series motor windings.

|

|

|

|

| Brushless motors for small size, high efficiency, and low heat |

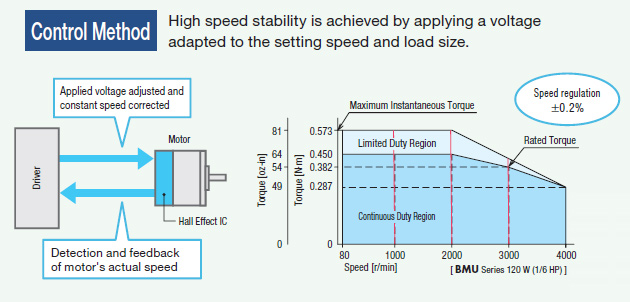

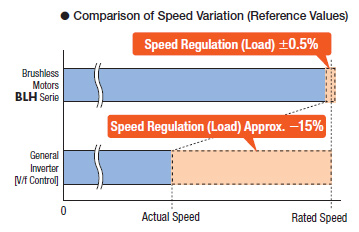

- Brushless motors are ideal for variable speed applications requiring speed regulation from feedback.

- Brushless motors are compact in size. Pump designs can be made smaller.

- Brushless motors generate less heat even at high-speed rotation so that heat-related issues can be avoided.

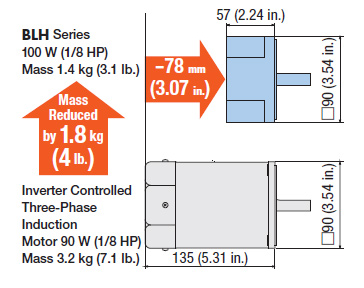

The BLH Series comprises a brushless DC motor or gearmotor and a dedicated variable speed driver. Various motor sizes are available from 15 to 100 W with parallel offset shaft, parallel centered shaft, and flat hollow shaft gearhead options. Also, three driver types for user control flexibility: analog setting, digital setting, and RS-485 communication type. With the dedicated driver, functions such as torque limiting and status monitoring are available.

|

Our peristaltic pump customers also mentioned these common benefits from both the PKP Series and BLH Series.

| Gears and drivers can expand the motor's capability and guarantee performance |

- A variety of gear options are available from both PKP Series and BLH Series to increase torque.

|

|

By adding a gearhead to a motor, its output torque can be vastly increased by the gear ratio and efficiency. The new CS geared stepper motor offers more permissible torque than an SH geared stepper motor. The radial load also increased.

A wide variety of gears are available to suit various designs for stepper motors and brushless motors.

| Gear Types | |||||

| PKP Series Stepper Motors | BLH Series Brushless DC Motors | ||||

| Spur Offset (SH) | Spur Centered (CS) | Flat Harmonic | Spur Offset (GFS) | Spur Centered (CS) | Flat Hollow (GFS) |

|

|

|

|

|

|

- Dedicated drivers maximize the performance of motors, such as low vibration and speed regulation.

|

|

Some advantages of using a dedicated driver are improved and consistent performance, such as low vibration, positioning accuracy, or speed regulation. Since Oriental Motor's specifications are typically derived from testing both the motor and driver together, we can guarantee our specifications.

| For PKP Series: CVD Drivers (right-angle/board mount) | For BLH Series: BLH Series (drivers included) | ||||

| Standard | RS-485 | S-Type | Analog | Digital | RS-485 |

|

|

|

|

|

|

Recap

A stepper motor's high starting torque and stop accuracy characteristics make them ideal for precise flow adjustments, while a brushless motor offers small size, high efficiency, and low heat. The variety of sizes, types, gear options, and driver lineup from both the PKP Serie and BLH Series makes them intriguing options for our customers.

Backed up by Oriental Motor's quality reputation and support from dedicated teams, these products offer true value as dependable options in the industry.

Need help with pumps?

Please contact our experts.