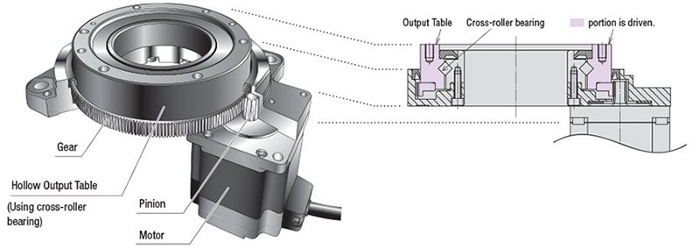

Hollow rotary actuators are useful in motor applications such as rotary index tables where the electrical cables or piping can fit through the center hollow bore of the actuator. Furthermore, mechanical parts, such as belt and pulleys, are eliminated by the hollow ring gear to minimize footprint.

Here's a video of an articulated robotic arm assembly being rotated by the hollow rotary actuator.

| Product Design & Benefits |

The DGII (DG2) Series hollow rotary actuator uses an AZ Series absolute stepper motor to drive a hollow output table attached to a hollow ring gear. The hollow bore diameter can be as big as 100 mm to fit necessary cabling and/or piping. The cross-roller bearings can support a high amount of thrust, radial and moment loads for its size while ensuring accuracy and durability. The built-in battery-less mechanical absolute encoder eliminates external home and limit sensors. 2 reduction ratio options are offered at 18:1 and 36:1 to eliminate additional belt and pulleys.

| Flexible Configurations |

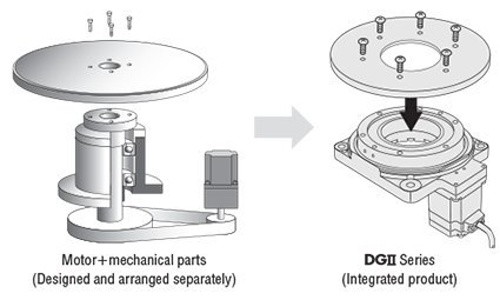

Multiple configurations offer more flexibility in installation of these hollow rotary actuators. Two examples are shown below.

Vertical Motor Mount Type

|

The original design of the DG and DG2 Series hollow rotary actuators only offered a vertical mount type as shown above (on the right side). The motor's pinion shaft faces upward. |

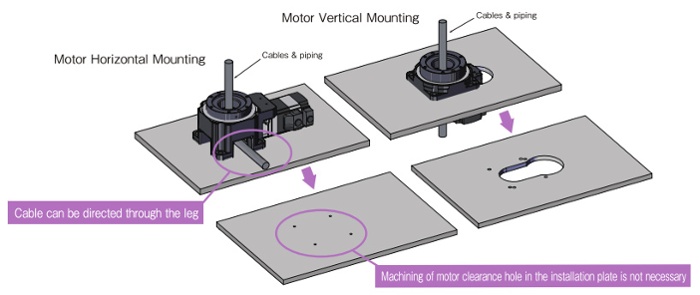

Although this was ideal for customers who were looking for a lower height profile hollow rotary actuator, extra work was necessary to cut a hole in the mounting plate or table for the motor to fit through. Who wants to do extra work?

Horizontal Motor Mount Type

|

Recently, a newer horizontal motor mount type hollow rotary actuator was released. With the motor's pinion shaft now facing sideways, a motor clearance hole is no longer necessary. |

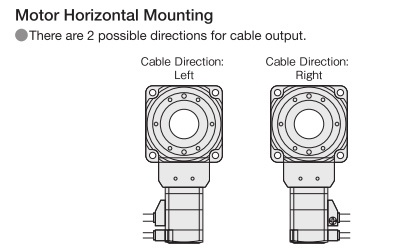

There are two configurations for cable outlet direction: left or right.

3rd Option: Vertical Motor Mount Type with Installation Pedestal

With an installation pedestal (additional accessory) machining of a motor clearance hole in the installation plate is eliminated. However, the height profile is increased.

| Pedestal | Pedestal with hollow rotary actuator |

| Summary |

|

The horizontal motor mount type is ideal for users who want the easiest and cost-effective mounting configuration. The height profile is reduced to 73 mm. The vertical motor mount type is ideal for users who want the lowest height profile (35.5 mm) from the installation plate. However, a hole needs to be cut in the plate for the motor. The vertical motor mount type can also be used with an installation pedestal, which eliminates the need to cut a hole in the plate. However, the height profile increases to 107.5 mm. |

For more information about the DGII (DG2) Series hollow rotary actuators, including lineup, features, accessories and downloads, please click below.

Thanks for reading! Please subscribe or check back for my next post.