The MEXE02 support software is a universal motion control and monitor software used with multiple products from Oriental Motor, such as the AZ Series, RK2 Series, BLE2 Series, and BX2 Series. This article is useful for first-time users to gain a quick understanding of the software and what it can do.

The  can be easily

can be easily  from our website whenever a user needs to program, monitor or troubleshoot a motor that is paired with a stored data type driver (with built-in controller). A

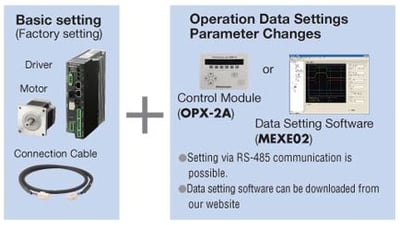

from our website whenever a user needs to program, monitor or troubleshoot a motor that is paired with a stored data type driver (with built-in controller). A  communication cable is required for all products except the AZ Series.

communication cable is required for all products except the AZ Series.

The programming method of the MEXE02 software differs from traditional stored program type controllers. Instead of writing long programs and subroutines, data sets are written in the form of a table. Each data set contains parameters for a specific motion profile with its own starting speed, operating speed, acceleration/deceleration rates, and torque (current)...etc. Stored data motion control can also be referred to as "point-to-point" motion control. Operational control between data sets is done via binary coded decimal inputs from a PLC, or by communication through an industrial fieldbus network. For multi-axis repetitive motion that do not require the use of variables, programming can be done more quickly and intuitively. Other data input methods are also possible either through an industrial fieldbus network or with a hand-held control module.

Features of the MEXE02 Software:

- Advanced Programming with Simple Sequence Functions

- Unit Setting Wizard

- Intuitive Data Setting & Operation

- Easy Data Exchange

- Teaching & Remote Operations

- Oscilloscope-like Waveform Monitor

- Multiple Screens at the Same Time

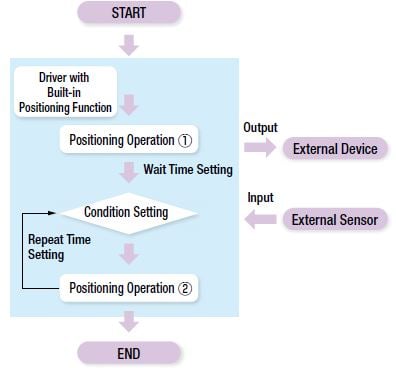

Advanced Programming with Simple Sequence Functions

For drivers with a built-in controller (Stored Data), you can easily incorporate functions that are normally performed by a PLC, such as utilizing output signals internally or sensor input signals to perform tasks (AZ Series). For other products, such as the AR Series or RK2 Series, different types of linked motion can be performed while minimizing the burden on the PLC.

|

|

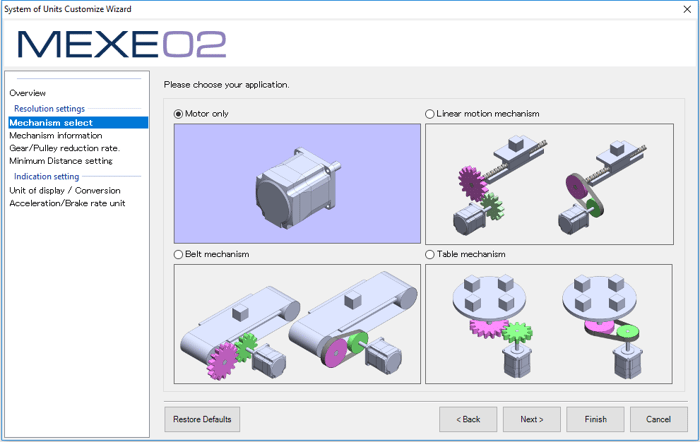

Unit Setting Wizard

This is a useful function that allows the travelling amount, speed, etc. to be displayed and input in the designated units (mm, degree) according to the mechanism used. This eliminates repetitive manual unit conversions and shortens programming cycles.

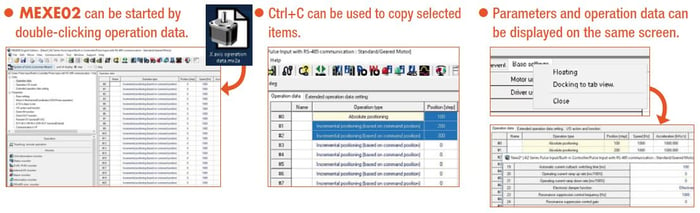

Intuitive Data Setting & Operation

Stored Data programming is intuitive. Double clicking opens the saved data file and displays it on the MEXE02 data screen. CONTROL-C can be used to copy selected cells. Parameters and operation data can be displayed on the same screen.

Easy Data Exchange

The Stored Data .mx2 file can be easiy downloaded from the driver and uploaded to other drivers. You can also select the type of data to be written. This is helpful for replacements, production line expansions, or troubleshooting.

Teaching & Remote (Test) Operation

The Stored Data and system parameters can be tested each step of the way before connecting to upper level controllers, such as a PLC or an industrial PC. This is useful when testing Stored Data sets to see if the motor system does what you intended it to. The window also displays the command position, actual position, actual speed, alarm condition, data set values, and jogging/homing functions.

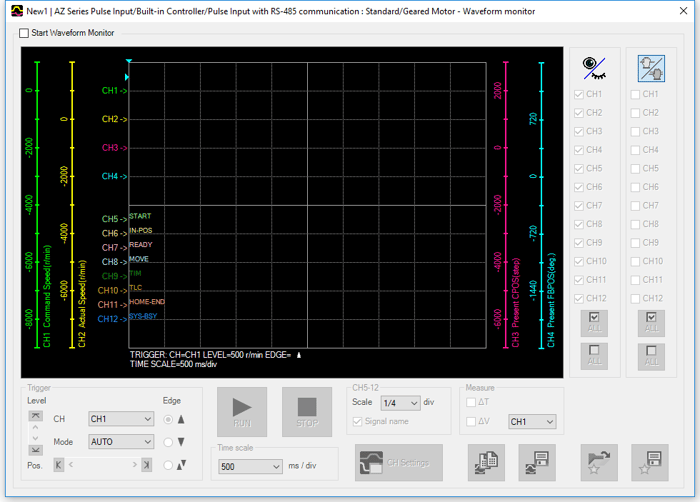

Oscilloscope-like Waveform Monitor

The waveform monitor can be used to provide visual representations of I/O signals or motion profiles. Parameters can be easily customized to show different combinations.

Multiple Monitor Screens at the Same Time

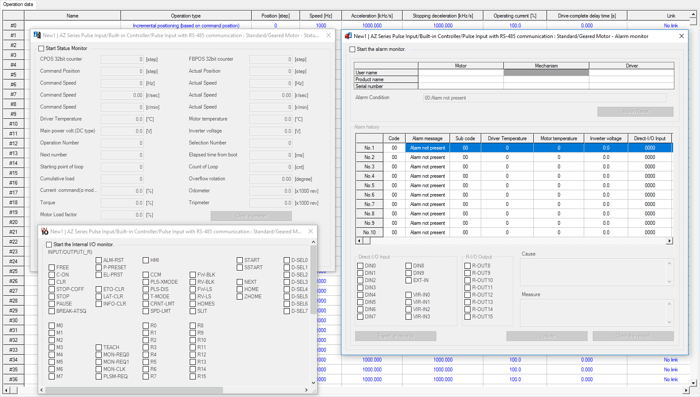

Multiple monitor screens can be displayed in real-time. The following example shows 3 monitor screens running at the same time: status monitor, I/O monitor and alarm monitor. This useful during the testing phase or complex troubleshooting cases.

Here is an MEXE02 introduction video. In addition to this video, more instructional videos have been uploaded online to teach you how to program specific motion sequences and application examples using Stored Data drivers and the MEXE02 software.

Wait. There's more...

One last thing to note here is that since different products offer different features and capabilities, the MEXE02 software interafce looks slightly different when connected to different products.

For example, the MEXE02 software interface changes when connected to BLE2 Series drivers vs RK2 Series drivers vs AZ Series drivers. Once the product is connected to the MEXE02 support software, the product can be automatically identified, and standard parameters are uploaded.

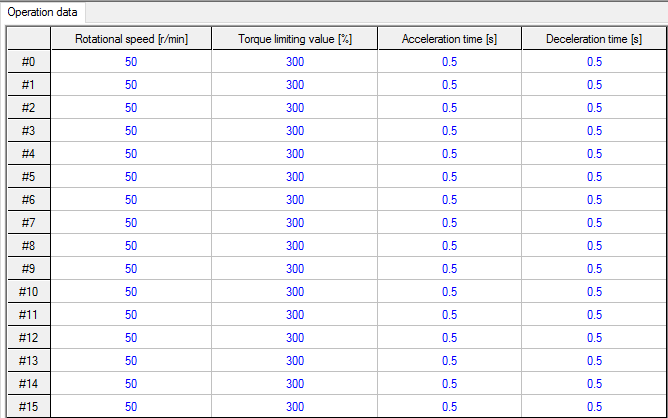

The screenshots below show what the software interface looks like when connected to a BLE2 Series stored data driver. The BLE2 Series brushless motors and drivers are designed for speed control. 16 unique data sets can be programmed with their own speeds, acceleration/deceleration rates, and torque limit settings.

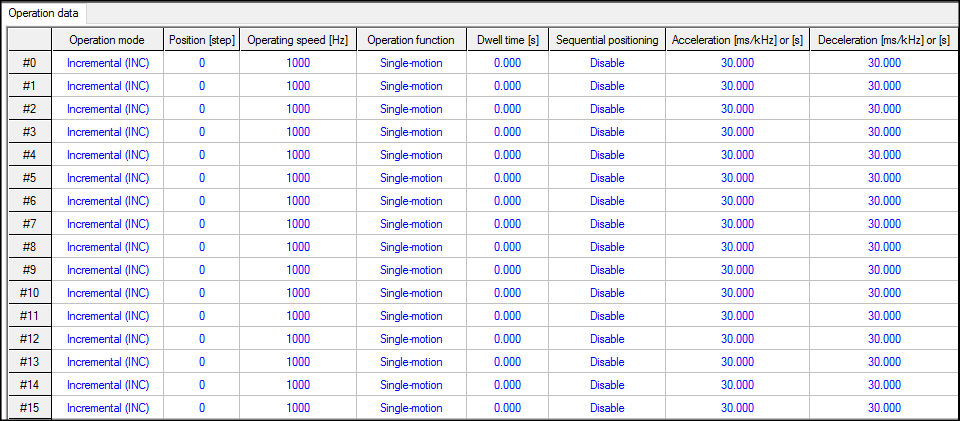

The screenshots below show what the software interface looks like when connected to an RK2 Series built-in controller, stored data type driver. Since the RK2 Series stepper motors and drivers are designed for position and speed control, more parameters appear in the software. 64 data sets can be programmed with specific position, speed, torque limit, and dwell time...etc.

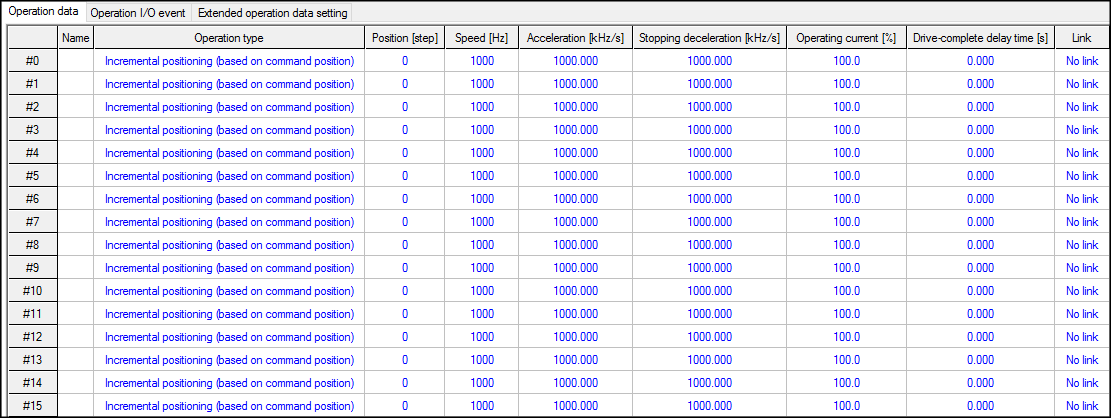

The screenshots below show what the software interface looks like when connected to any of the AZ Series pulse input, built-in controller with RS-485, or pulse input with RS-485 type drivers. The AZ Series drivers are used with advanced closed-loop stepper motors with absolute position feedback for both position and speed control, so the interface would have more options than the RK2 Series and the BLE2 Series. Up to 256 data sets are available as well as advanced stored data functions to do what stored program controllers can do; including loops and conditional jumps.

Traditionally, stored data (point-to-point) motion control is used for simple, repetitive motion. Stored program type motion control has been preferred for complex variable motion control. However, stored data (point-to-point) motion control has come a long way in its ability to do more complex motion.

When combined with AZ Series products, the full extended capabilities of the MEXE02 software can be utilized. For example, a looping reciprocating motion of 100,000 cycles (see Automatic Sequential under Link) or conditional jumps based on input signals (see Event Trigger under Operation I/O Event) can be done with built-in extended stored data functions. To overcome the limitations of moves (256) and re-write cycles (100,000), there are methods, such using the Simple Direct Data Operation or Group Send with an industrial fieldbus network, to increase the number of unique moves as well as minimizing the number of write cycles to the non-volatile memory.

Please contact our  for additional tips, or click below for videos that show how to program specific motion sequences by using the MEXE02 software.

for additional tips, or click below for videos that show how to program specific motion sequences by using the MEXE02 software.