Interested in industrial robots but not sure where to start? Learn how Oriental Motor's compact and easy-to-use small industrial robots, robot controllers, and software can help simplify robotic automation.

Topics Covered:

- Hit the Easy Button

- What Types of Robots are Included in the OVR Series?

- Articulated Robots

- SCARA Robots

- Cartesian Robots

- Robot Control and Programming

- Try Out Our New Test Tools

- OVR Series Robots in Action

Building a robot is not easy. It involves designing, selecting, assembling, integrating, programming, and testing various components and making sure they work in synchronization with other axes to perform specific tasks. It is much easier said than done. There are also many mechanical, control, precision, and safety parameters to consider:

Mechanical Considerations:

- Must be rigid for precision but light for speed

- Complex joint design with minimal backlash

- Thermal expansion affects accuracy

Control Considerations:

- Real-time processing (millisecond responses)

- Complex mathematics for movement: p=f(θ1,θ2,...,θn)p = f(θ_1, θ_2, ..., θ_n)p=f(θ1,θ2,...,θn) (coordinate transformation)

- Must account for inertia, gravity, friction

Precision Considerations:

- Repeatability (±0.01mm typically)

- Maintain accuracy under varying loads/speeds

- Requires high-quality sensors and feedback

Safety Considerations:

- Emergency stops, collision detection

- Speed/force limits

- ISO compliance

All selected components, such as motors, gearheads, actuators, drivers, and even couplings, must meet the required specifications. Each type of robot also has its own unique challenges. For example, SCARA needs selective compliance, Cartesian needs precise linear motion, and articulated robots need complex joint coordination. For basic information on how to build an articulated robot, please refer to this article: How Easy Is It to Build a Robot?

Is there an even easier way?

Hit the Easy Button

More often than not, it's easier to buy a robot. To help engineering teams that don't necessarily have the resources or team size to build robots but are interested in robotic automation, Oriental Motor has released a line of easy-to-use compact industrial robots designed to transfer small parts.

Customers can select from a 4, 5, or 6-axis Vertically Articulated robot, a 3-axis SCARA robot, or a 3-axis Cartesian robot and combine it with an end-effector, such as our 2 or 3-finger gripper.

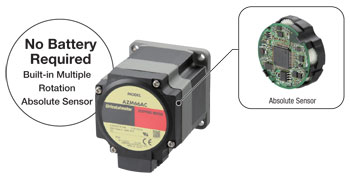

| All the moving axes utilize motors, linear/rotary actuators, and mini drivers from the AlphaSTEP AZ Series Hybrid Step-Servo Product Family. With its patented mechanical absolute encoder technology, absolute position control can be achieved without a backup battery, such as in the case of an optical absolute encoder. |  |

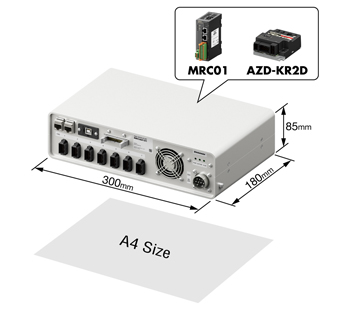

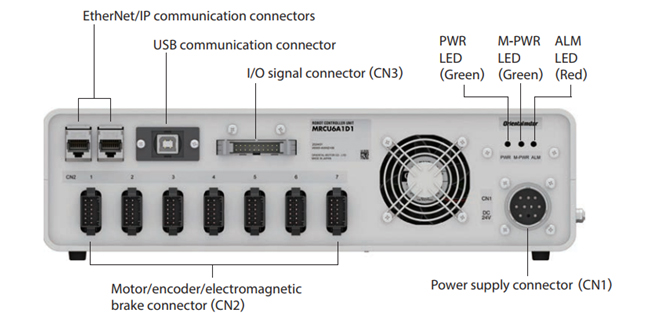

To help simplify the programming of these types of robots, we have also released new MRCU Integrated Robot Controllers, which combine the powerful MRC01 Robot Controller and up to 7 AZ Series mini drivers in a small box. The drivers, cables, and the Robot Controller are pre-assembled, which means that all users have to do is connect the motors, actuators, or grippers.

What Types of Robots are Included in the OVR Series?

The OVR Series lineup includes 3 types of compact industrial robots that can provide a cost-effective alternative to similar industrial robots in the market. The entire robot, as well as its drivers and controllers, can be powered by a single DC power supply, which means that these robots can easily be mobile as well. By using modular, standard components instead of custom components, these small robots can help reduce costs, shorten lead times, and simplify maintenance.

| New Articulated Robot | New SCARA Robot | New Cartesian Robot |

|

|

|

|

|

|

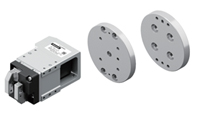

For the end-effector (wrist rotation) on the vertically articulated robots, a Robot Flange Adapter that conforms to ISO 9409-1-31.5-4-M5 standard is available to mount our EH Series compact gripper. If another manufacturer's end-effector is preferred, adapter plates can be purchased from other manufacturers. For the SCARA and cartesian robots, a custom adapter plate can be made.

|

|

Application: capable of approaching and picking parts from multiple directions.

These vertically articulated robots are our best sellers in Japan and offer the highest payload in the OVR Series. There are 3 models available with different movable ranges (4-axis, 5-axis, and 6-axis). The arms can be replaced by different lengths for some customization. The 6-axis articulated robot offers the maximum degree of freedom and can approach the load from different angles.

| # of Axes | 4-Axis | 5-Axis | 6-Axis | |

| Design |  |

|

|

|

| Feature |

Parallel link mechanism |

Compact and lightweight |

Approach the load from various angles |

|

| Maximum Reach (Horizontal) |

480/680/880 mm |

350 mm |

480 mm |

|

| Transportable Mass | 5 kg | 1 kg | 1 kg |

Here's what the 6-axis vertically articulated robot looks like. We also break down its motion axes and control components.

Components of a 6-Axis Vertically Articulated Robot

|

Robot Model: OVR6048K1-V Axis 1: DGII Series Hollow Rotary Actuator Axis 2~5: AZ Series Hybrid Step-Servo Motors Axis 7? Connect your own end-effector (Shown: EH Series 3-Finger Type Compact Gripper) |

|

|

|

Integrated Robot Controller: MRCU6A1D* *Contains MRC01 Robot Controller (1 pc) + AZD-KR2D mini Drivers (6 pcs) |

|

Various end-effectors can be used to pick up parts at the end of the arm (7th axis), including our 2 and 3-finger type EH Series compact grippers. For light loads (up to 5 kg), these articulated robots can serve as cost-effective alternatives to other small robots in the market. The 5-axis and 6-axis articulated robots can also be combined with an electric linear actuator or a mobile robot to meet linear travel or mobile requirements.

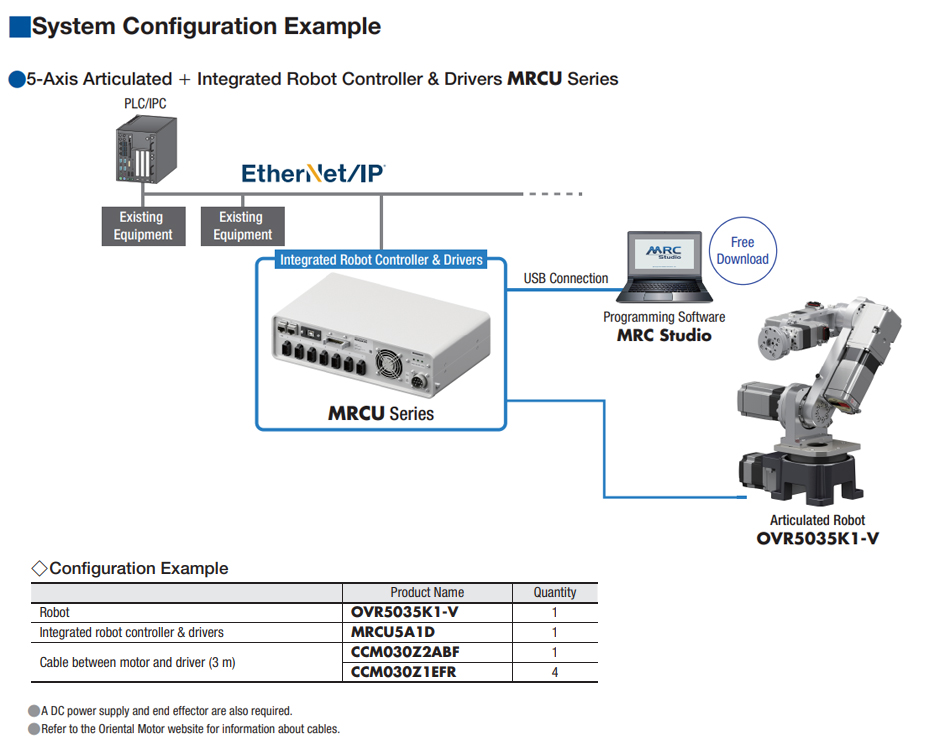

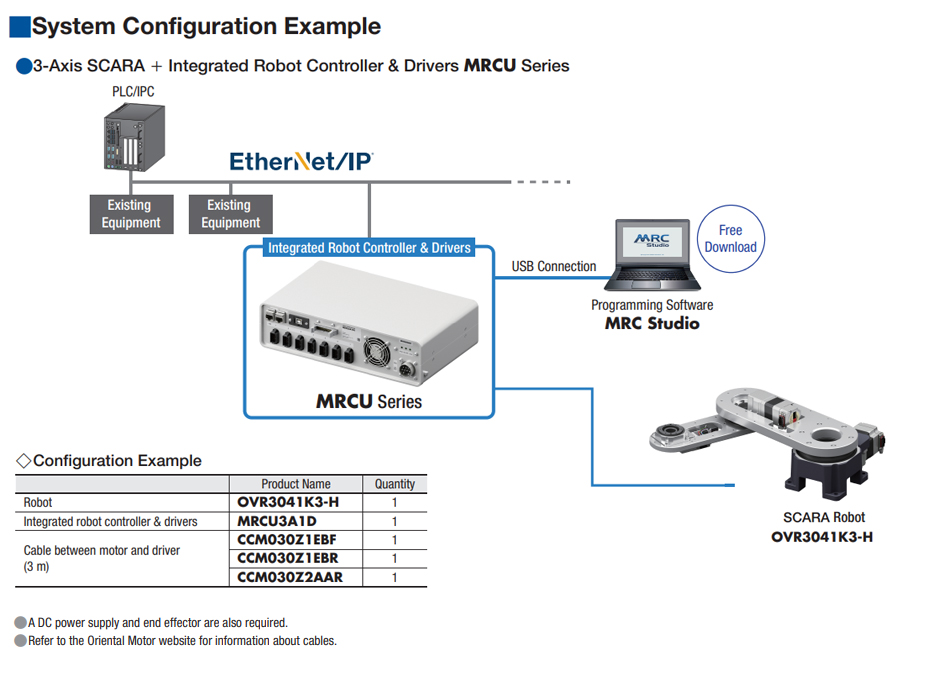

This system configuration example shows how the robot can be connected to the MRCU Series Integrated Robot Controller and other existing equipment, such as a PLC/IPC.

Horizontally Articulated (SCARA) Robots

Application: capable of moving parts in and out of narrow spaces.

This 3-axis horizontally articulated (SCARA) robot is offered in a 3-axis configuration. The space-saving, low-profile design of the SCARA robot makes it possible to move parts in and out of tight and narrow spaces. A DGII Series Hollow Rotary Actuator is used at the base of the SCARA robot to handle handle high moment loads.

| # of Axes | 3-Axis |

| Design |  |

| Feature |

Low-profile design |

| Maximum Reach (Horizontal) |

410 mm |

| Transportable Mass | 3 kg |

The vertical height of the OVR Series SCARA robot is only 137 mm.

Here's what the 3-axis SCARA robot looks like. We also break down its motion axes and control components.

Components of a 3-Axis SCARA Robot

|

Robot Model: OVR3041K3-H Axis 1: DGII Series Hollow Rotary Actuator Axis 2: AZ Series Hybrid Step-Servo Motors Axis 3: DGII Series Hollow Rotary Actuator Axis 4? Connect your end-effector (Shown: EH Series 2-Finger Type Compact Gripper) |

|

|

3-Axis Integrated Robot Controller: MRCU3A1D* *Contains MRC01 Robot Controller (1 pc) + AZD-KR2D mini Drivers (3 pcs) |

|

Various end-effectors can be used to pick up parts at the end of the arm (4th axis), including our 2 and 3-finger type EH Series compact grippers. If you need a low-profile SCARA robot to pick up small parts in a narrow space, this robot can be your answer. This SCARA robot can also be combined with an electric linear actuator or a mobile robot to meet linear travel or mobile requirements.

This system configuration example shows how the robot can be connected to the MRCU Series Integrated Robot Controller and other existing equipment, such as a PLC/IPC.

Application: approaching and moving parts in fixed cartesian XYZ coordinates.

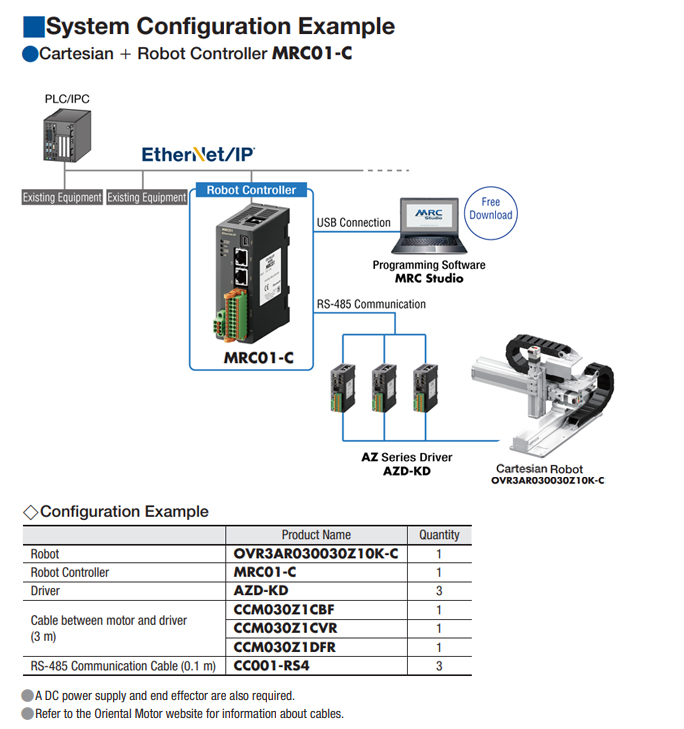

This 3-axis cartesian robot is delivered pre-assembled with 3 linear slides. This is also the only type of robot that uses the MRC01-C Cartesian Robot Controller, which is a simplified version of the MRC01 Robot Controller. The MRC01 will also work, but the simpler MRC01-C is offered at a lower price point.

| Type | L Type | R Type | |

| Design |  |

|

|

| Feature |

Easy to control |

||

| Maximum Reach (Horizontal) |

300 (X) x 300 (Y) x 100 mm (Z) |

||

| Transportable Mass | 2.5 kg | ||

Here's what the 3-axis cartesian robot looks like. We also break down its motion axes and control components.

Components of a 3-Axis Cartesian Robot

|

Robot Model: OVR3AR030030Z10K-C Axis 1~3: EZS Series Motorized Slide Actuators Axis 4? Connect your own end-effector (Shown: EH Series 2-Finger Type Compact Gripper) |

|

|

On the vertical Z-axis, various end-effectors can be installed on the moving table to pick up parts, including our 2 and 3-finger type EH Series compact grippers. The 5-axis and 6-axis articulated robots can also be combined with an electric linear actuator for linear travel.

This system configuration example shows how the robot can be connected to the MRC01 Robot Controller, the AZD-KR2D mini drivers, and other existing equipment, such as a PLC/IPC.

Robot Control and Programming

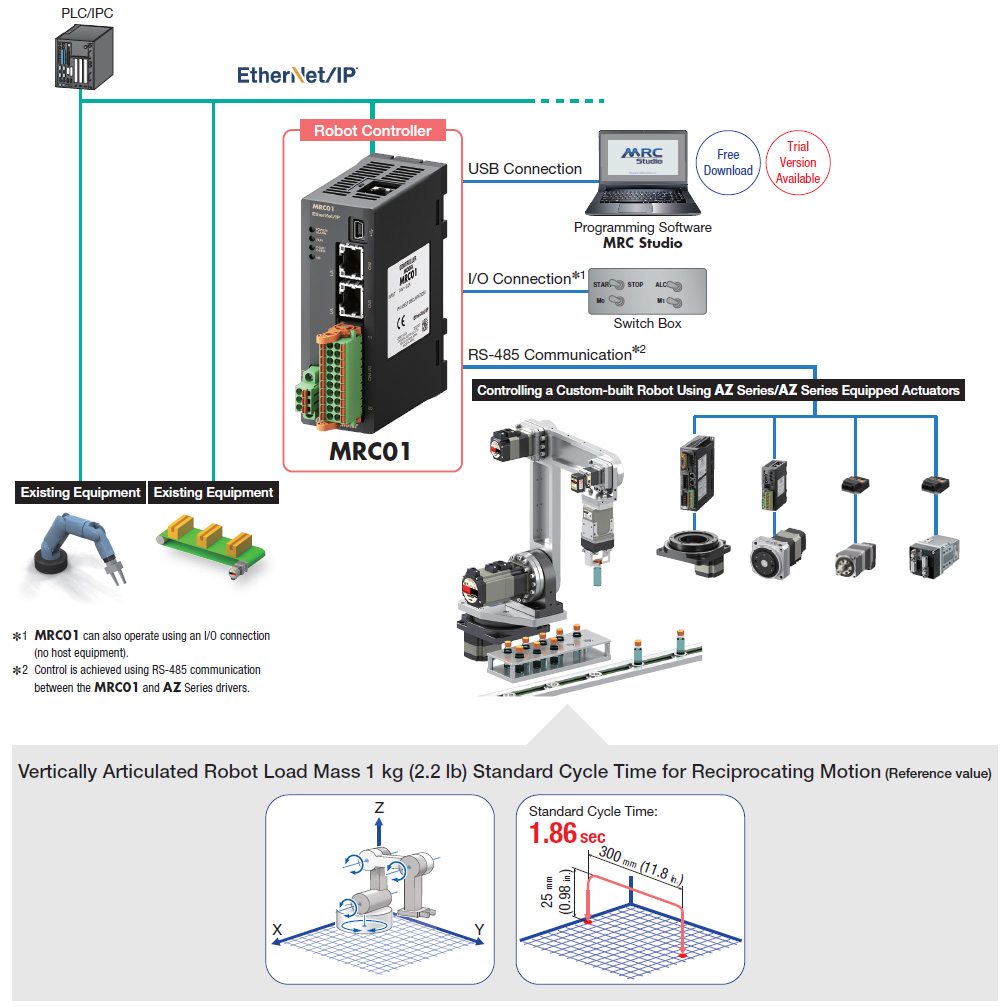

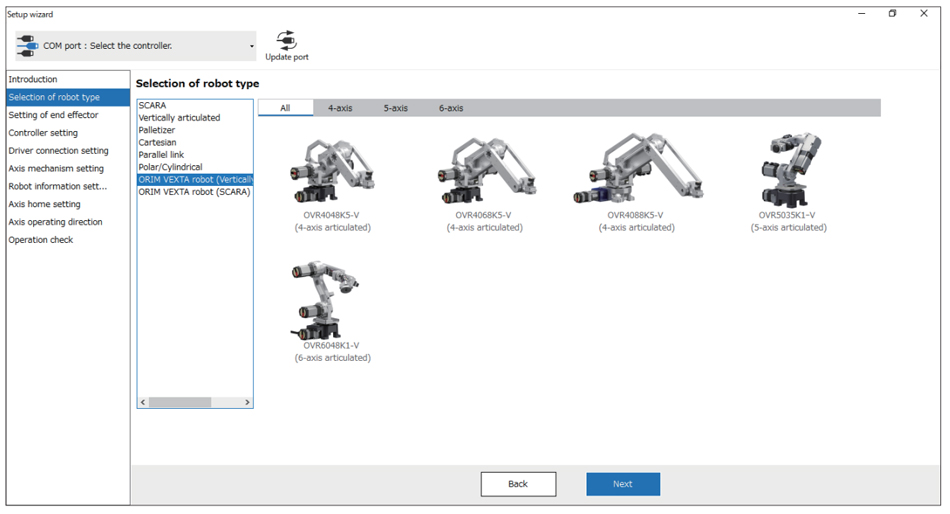

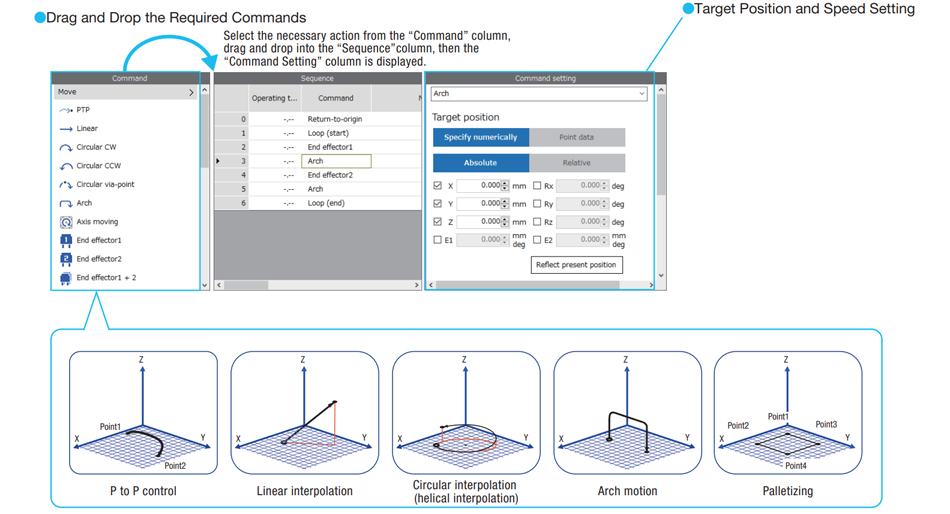

With the MRC01 Robot Controller and MRC Studio software, up to 7 axes of SCARA, cartesian, and articulated robot motion axes can be easily programmed even without prior programming experience. An MRC01 Robot Controller can be configured for 59 different types of robots and store up to 64 programs with 128 commands each.

- Motion Commands: Point-to-Point, Linear, Circle (with helical interpolation), Arch

- Control Commands: Stand by (Time), Stand by (Signal), Loop, and Signal output

In addition, the MRC01 Robot Controller can communicate with the host controller (PLC/IPC) via EtherNetIP for data setting or monitoring.

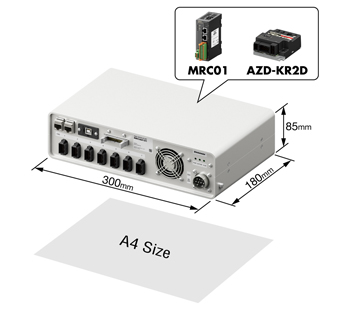

An MRCU Series Robot Controller combines an MRC01 Robot Controller with multiple AZ Series DC-input mini drivers in a compact box, so all you have to do is connect the cables externally.

| New MRCU Multi-Axis Robot Controller |

|

|

|

With its intuitive interface, the MRC Studio programming software can be downloaded to program these small robots. No programming experience is necessary to use the software.

Easy SetupJust select the type of OVR Series robot to begin setting up the stored data inside the Robot Controller. In addition, the MRC01 Robot Controller or any MRCU Series Integrated Robot Controller can communicate to a host controller via EtherNetIP for data setting, I/O commands, or monitoring. |

|

|

No Ladder LogicJust drag and drop the required commands, including target positions and speed settings. No ladder logic experience (or any programming experience) is necessary. |

Try Out Our New Test Tools

|

MRC Simulator Software A trial version of the software can be downloaded for testing. |

MRC Reality (Augmented Reality) Use the AR/MR robot function to visualize, simulate, or teach. |

|

|

OVR Series Robots in Action

Oriental Motor not only builds robots, but we also use them to increase production efficiency and reduce errors in our own production lines.

| SCARA Robot in Sensor Assembly Line | Articulated Robot Applying Grease to Ball Screws |

|

|

Robots are a significant investment. According to Perplexity, the starting price of a 6-axis vertically articulated robot capable of handling parts up to 5 kg in the United States can be from as low as $15,000 to $25,000, then the cost of the end-effector, controllers, cables, safety devices, advanced features, integration, programming, support, and training are added to the cost. The OVR Series small industrial robots are great alternatives for users looking for more compact and cost-effective options other than those provided by bigger brands.

As always, you can contact an Oriental Motor sales engineer or technical support engineer for a full product introduction or to answer any questions. Our new robot support team is prepared to answer questions and have the ability to demonstrate specific motion sequences for proof-of-concept in our new robot demo room.