With the growing popularity of efficient brushless motors, replacing AC motors with these motors brings several advantages. In this blog post, we will uncover one of the advantages that can benefit lighter and compact equipment designs.

Brushless motors are much more power efficient than AC induction motors. This means a smaller brushless motor can do the work of a bigger AC motor.

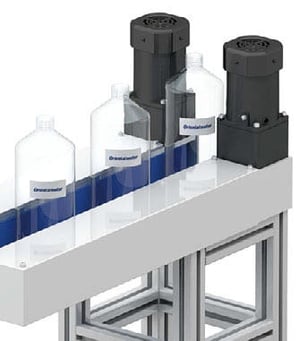

An ideal application example is shown below with a grip conveyor that has two belts on either side, driven by two AC induction motors. AC motors are not the most efficient option when it comes to power-to-torque conversion. Therefore, the motors need to be bigger and heavier than they really need to be.

Conventional Equipment: Grip conveyor with two belts on each side driven by two AC gear motors. An inverter (VFD) is typically used for speed control (not shown).

Problems with Conventional Equipment:

- Larger AC motors are bulky and heavy to handle and install.

- An additional support frame is often necessary

- Since 2 motors are used, the motor mass makes a bigger difference

SOLUTION BMU Series brushless gear motor + AC input driver

Use a compact and high power  to reduce the motor size and mass on the grip conveyor. A heavier motor may require a support frame to support its weight on the machine. This makes the conveyor heavier, more expensive, and more difficult to install. By replacing the AC motors with more compact, efficient brushless motors, we are able to reduce the motor protrusion on the top of the conveyor as well as the mass of the motors.

to reduce the motor size and mass on the grip conveyor. A heavier motor may require a support frame to support its weight on the machine. This makes the conveyor heavier, more expensive, and more difficult to install. By replacing the AC motors with more compact, efficient brushless motors, we are able to reduce the motor protrusion on the top of the conveyor as well as the mass of the motors.

Advantages offered by BMU Series:

- More efficient than AC motors

- Lighter & compact motors

- Easier installation & maintenance

- Uses same input voltage for driver

- IP66 motor+

| Oriental Motor AC Induction Motor | BMU Series | |

| Output Power | 90 W (1/8 HP) | 60 W (1/12 HP) |

| Frame Size | □ 90 mm (3.54") | □ 80 mm (3.15") |

| Gear Type | Parallel Shaft | Parallel Shaft |

| Gear Ratio | 9:1 | 30:1 |

| Permissible Torque | 4.2 N·m (37 lb-in) | 5.2 N·m (46 lb-in) |

| Mass | 4.7 kg (10 lbs) | 1.4 kg (3 lbs) |

RESULT: The mass can be reduced by 6.6 kg (3.3 kg per unit)

how easy it is to operate a BMU Series brushless motor and driver

how easy it is to operate a BMU Series brushless motor and driver

Because of feedback control, brushless motors also offer much better speed regulation than AC induction motors. With recent trends in efficiency, brushless motors should be considered during the motor selection process for new designs.