With recent trends focusing on improving engineering efficiency, many products have been developed to specifically help shorten design cycles for machine automation. Part of improving efficiency is making products easier to use, so additional time and resources can be spent elsewhere. This post describes a product feature that can make index table applications less complex to manage.

|

|

APPLICATION EXAMPLE: rotary index table that rotates a fixed distance repeatedly in the same direction. A motorized rotary actuator is installed below the index table. The product video below shows a similar application example of a syringe dispensing application; also with a rotary actuator. |

| For an index table that rotates a fixed distance repeatedly in the same direction, position management can be difficult since the internal position counter value keeps increasing. Some mathematical calculations are necessary to convert the step count to degrees before the operator can understand where the table is actually facing. |

|

For example, let's say we are positioning 90 degrees at a time with a motor that has a basic step resolution of 200 steps per revolution, or 1.8° per step. The position counter value will look like this:

| Steps | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| Degrees | 0° | 90° | 180° | 270° | 360° | 450° | 540° | 630° | 720° | 810° | 900° |

On a rotary table, the same index positions repeat after 360 degrees, the actual position coordinates within 360° have to be calculated.

Here's a simple formula to figure out the actual position coordinates.

Actual Position = Current position in degrees - (360 x number of revolutions travelled)

For 900°, the rotary table has rotated more than 2 revolutions, so the formula will be:

Actual Position = 900° - (360° x 2) = 180° (from home position)

Is there an easier way to do this?

| Challenge |

| Manage 360° coordinates better by converting to absolute coordinates instead of steps |

For positioning management of index tables, it is easier to monitor the table position if the position count value can be set in degrees as well as clear the position counter once it passes 360°. For the above example, the position values can be converted from step count to degrees, which makes life just a little easier. Other functions, such as Wrap Proximity Positioning and Wrap Absolute Positioning, can be used to make position control and management even easier.

| Solution |

| Use the Wrap Function to reset position counter when appropriate |

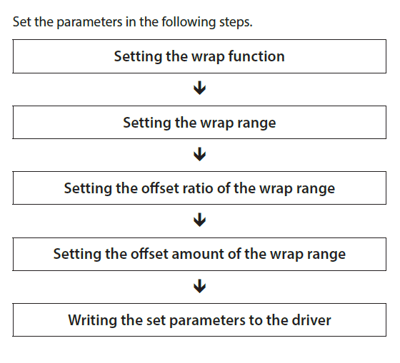

The Wrap Function automatically resets the position counter value to 0 when the motor output shaft exceeds a set value. For example, when the "Wrap Setting Range" is set to "1 rotation", the position counter value automatically resets to 0 when the motor shaft exceeds 360° from the home position. Gear ratios can also be added to additional adjustments.

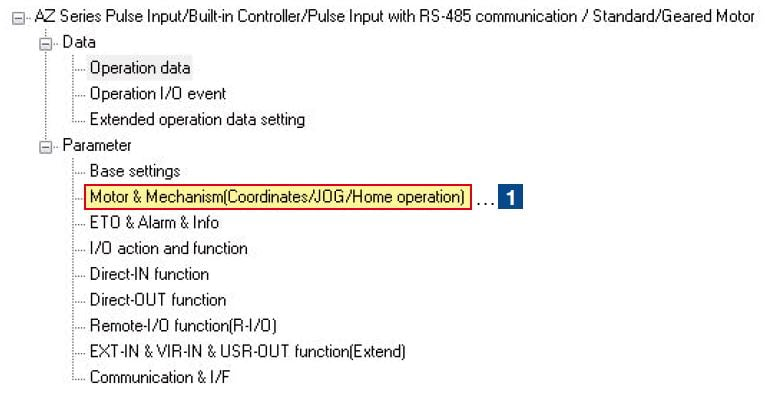

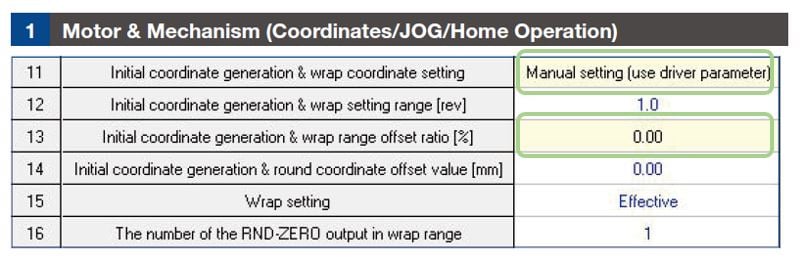

Here we show you a screenshot of the dedicated MEXE02 support software where it contains the Wrap parameter settings.

Left Menu:

Center Window:

The circled parameters are changed from their default values to make this possible.

| Initial Coordinate Generation & Wrap Coordinate Setting |

To use the wrap function, select manual Setting range: ABZO sensor or manual |

| Initial Coordinate Generation & Wrap Setting Range (rev) |

Sets the wrap range. The command position Setting range: 5 to 655,360 (1=0.1 rev) |

| Initial Coordinate Generation & Wrap Range Offset Ratio (%) | Set the offset ratio of the wrap range. Setting range: 0 to 10,000 (1=0.01%) |

| Wrap Setting | Enable or disable |

| The Number of the RND-ZERO output in wrap range |

Sets the number of times to turn the Setting range: 1 to 536,870,911 divisions |

Here's a video showing you how to set up the Wrap Function parameters for Oriental Motor's rotary actuators by using the MEXE02 support software.

Bonus: Learn the various types of Wrap positioning operations you can do with this video tutorial.

For more information about the Wrap Function, please refer to page 40 of the  .*

.*

*The DG II Series is the hollow rotary actuator version of the AZ Series.

The Wrap Function is available with products from the  , such as EZS linear slides, EAC linear cylinders, DGII Series rotary tables, DRS/DR compact cylinders, L rack and pinion systems, and EH gripper systems.

, such as EZS linear slides, EAC linear cylinders, DGII Series rotary tables, DRS/DR compact cylinders, L rack and pinion systems, and EH gripper systems.

Interested in learning more about the AlphaStep family?