Modern automation increasingly demands higher reliability, faster time-to-build, and easier scalability in a smaller package. If you’ve ever wished you had an easy button for motion control, Oriental Motor’s αSTEP Hybrid Step-Servo AZ Series product family lets you build your own compact, modular motion control solution by choosing off-the-shelf products.

For example, you can buy a motor, a driver, and a mounting bracket and build your own all-in-one integrated motor. With the Mounting Bracket for AZ Series mini Drivers, a mini driver can be mounted on a 42 mm or 60 mm frame size αSTEP ("AlphaSTEP") Hybrid Step-Servo motor from the AZ Series product family.

| Mounting Bracket for AZ Series mini Drivers | αSTEP Hybrid Step-Servo Gear Motor + AZ Series mini Driver |

|

|

This type of all-in-one, integrated motor configuration places the driver directly on the motor, saving space, time, and cabling. If linear motion is required, we can also attach a linear actuator (we'll get to that).

What's Covered?

- What's Included in the All-in-One Configuration?

- How to Build an All-in-One αSTEP Hybrid Step‑Servo Motor

- How and Where This All‑in‑One Configuration Can Accelerate Your Designs

- How to Get Started

- Tips from Our Tech Support Engineers

What's Included in the All-in-One Configuration?

1 αSTEP AZ Series Hybrid Step‑Servo Motor (Connector Type Required)

Part number example: AZM66AKH

Description: 60 mm frame size DC input connector type αSTEP Hybrid Step-Servo motor

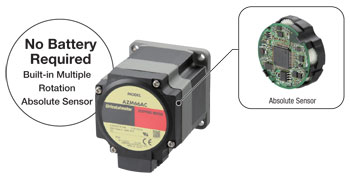

The αSTEP AZ Series combines the precision of a stepper with the reliability of closed‑loop control via a built-in mechanical absolute encoder using magneto-resistive technology. This motor operates in open-loop in normal conditions but will switch into closed-loop mode once missteps are detected and correct on the fly. The mechanical absolute encoder is magnetic in nature and is more robust than optical encoders. It can work in more environments and can eliminate backup batteries typically required by optical encoders as well as external home and limit sensors. That means no homing routine is required even after power loss —saving downtime while reducing heat and enabling high efficiency and low vibration compared to open‑loop control.

Geared motors are also available in an all-in-one integrated configuration. TS (Tapered Spur), PS (Planetary), and HG (Harmonic) gear motors are available. However, the FC right-angle gear motors are not compatible.

Key Characteristics:

- Battery‑free and sensor-less absolute position control

- Closed‑loop hybrid step-servo performance without hunting or gain tuning (common with servos)

- Preassembled with various gear types and gear ratios for larger inertial loads

2 AZ Series mini Driver

Part number example: AZD-KREP

Description: AZ Series DC input stored data mini driver with EtherNet/IP communication

The αSTEP AZ Series DC input mini drivers are our smallest and lightest driver for the αSTEP AZ Series hybrid step-servo motors. Fully functional with stored motion data and system parameters, the mini driver mounts directly on the motor, minimizes footprint per axis, and also supports common factory networks. EtherCAT, EtherNet/IP, PROFINET, Ethernet (Modbus TCP), Modbus/RS‑485, as well as a basic pulse input type, are available to satisfy various control requirements. The driver’s servo‑emulation current control optimizes motor current to match the load for more energy savings and lower operating temperatures.

Key Characteristics:

- Compact & lightweight; two‑screw mounting directly to equipment (no DIN rail).

- FA network compatible for centralized control and simplified wiring.

- Accepts 24/48 VDC (battery‑friendly), with connection cables up to 10 m for flexible layouts. [3]

3 Mounting Bracket for AZ Series mini Drivers (Accessory)

Part number example: MAFP06W-6

Description: Mounting bracket for AZ Series mini driver and 60 mm frame size αSTEP hybrid step-servo motor

With this mounting bracket, the mini driver can be easily attached to the side of the AZ Series connector type motor. Installation is literally a clamp + two screws. It supports 42 mm and 60 mm frame sizes (round‑shaft or geared types except for the FC right‑angle gear) and enables a clean single‑cable motor‑to‑driver connection with the recommended 0.2 meter connector cables. With the driver mounted directly on the motor, no long cable is necessary is connect back to the driver in an enclosure.

Compatibility notes:

- Use 42/60 mm AZ Series DC input connector‑type motors and gear motors (except for the FC right-angle gear type)

- Use AZ Series mini Drivers: AZD-KRxx (except for the AZD-KR2D Modbus/RS-485 model)

4 AZ Series Motor-mini Driver Connection Cable (Accessory)

Part number example: CCM002Z1EBF

Description: 0.2 meter connector cable for 60 mm αSTEP AZ Series hybrid step-servo motor and mini driver

Easily connect an AZ Series hybrid step-servo motor to an AZ Series mini driver with a dedicated 0.2 meter cable. Both ends of the cable have dedicated connectors to connect to the motor and driver.

Compatibility notes:

- Use 42/60 mm AZ Series DC input connector‑type motors and gear motors (except for the FC right-angle gear type)

- Use AZ Series mini Drivers: AZD-KRxx (except for the AZD-KR2D Modbus/RS-485 model)

- When using the 0.2 m connector cable, maintain the 25 mm minimum cable bend radius, or build your own cable.

How to Build an All-in-One αSTEP Hybrid Step‑Servo Motor

- Size the αSTEP AZ Series motor based on torque, speed, and inertia (42/60 mm AZ Series DC input connector type only)

- Select the αSTEP AZ Series mini driver that matches your control preference (EtherCAT / EtherNet/IP / PROFINET / Ethernet (Modbus TCP) / Modbus RS‑485 / pulse input)

- Mount the bracket: place the bracket around the motor and clamp and tighten two screws

- Attach the mini driver to the bracket; orient according to your cable routing preference

- Wire the motor, power, and the host controller to the mini driver (dedicated cables are available as accessories)

- Set up motion with the MEXE02 software and tune motion profiles, alarms, and I/O mapping

Watch how easy it is to assemble an all-in-one motor.

|

Need Linear Motion? Simply attach a linear actuator like a gearhead.

Need linear motion that saves space and design time? Our Linear Actuator Attachments provide either a lead screw or rolled ball screw with a resin or iron nut mechanism that bolts directly to a stepper motor (like a gearhead; no couplings required). In 42 mm frame size configurations with rolled ball screw, you can achieve up to 160 N thrust with self‑locking for position holding without power. This turns your αSTEP hybrid step-servo AZ Series motor and mini driver into a compact stepper actuator for precise linear motion. If you don't need the αSTEP hybrid step-servo control, you can also use our PKP Series stepper motors. 🎗️Remember to verify thrust and lead specifications for your payload and cycle time. Our tech support engineers can help. |

How and Where This All‑in‑One Configuration Can Accelerate Your Designs

1) Compact & Cleaner Wiring

Mount the driver right on the motor and route one cable between them; fewer loose wires, smaller enclosures, and faster build times. Cable options range from 0.2 m (for integrated mounting) up to 10 m for flexible machine layouts.

2) Precision Without the Headaches

The mechanical absolute encoder delivers absolute positioning with reliable, closed‑loop hybrid step-servo control without batteries or homing sensors, which saves engineering time, eliminates parts costs, and decreases failures.

3) Fast Assembly

The bracket installs via two screws; no custom brackets or 3D‑printed mounts needed. The system looks and behaves like an integrated motor/driver, while still remaining modular for service and upgrades.

4) Performance & Efficiency

Mini driver current optimization reduces motor heat and power consumption compared to open‑loop steppers, while maintaining step‑servo‑like torque delivery and positioning stability.

5) Scalable Control Architecture

With universal software, networkable mini drivers with stored data capability, and plug-and-play capability, the αSTEP AZ Series Hybrid Step-Servo product family ensures new axes can be added quickly and easily.

Typical Application Examples

✅SCARA, Delta, and Small Cartesian RobotsSpace‑constrained joints benefit from the driver‑on‑motor form factor. Absolute positioning simplifies recovery after E‑stops or power cycles; no homing sensors on crowded end‑effectors.

✅Precision Indexing on Compact MachinesFor indexing tables or feeders where enclosure space is tight, the bracketed mini driver cuts wiring, and closed loop ensures repeatable dwell positions without overshoot/hunting.

✅Pick‑and‑Place & Vision Positioning StagesAdd the linear actuator attachment to convert rotary to linear—ideal for Z‑axes, focus stages, or fine dispensing. The self‑locking characteristic can hold position without power during maintenance.

✅Lab Automation & Portable SystemsThe mini driver’s 24/48 VDC acceptance and light weight make it a good fit for battery‑backed mobile carts or compact test fixtures.

✅Assembly & Inspection JigsThe battery‑free absolute encoder maintains the exact home position without batteries, external sensors, or a homing routine, speeding up maintenance and reducing complexity.

If your team needs precise, reliable, compact motion control without hours of bracket design, wiring, and sensor integration, this AZ Series all-in-one integrated configuration presents a fast and easy path from concept to motion - with less cabling, fewer parts, and more uptime. The driver‑on‑motor bracket makes your axis look and feel integrated while remaining modular.

How to Get Started

To start the process, please submit an appropriate motor sizing form so we can gather your application details. Our tech support engineers can size the right motor for your specific application as well as select the right accessories to get you going quickly. They can be reached via the website, phone, email, or chat during normal office hours.

|

👥Tips from Our Tech Support Engineers

|