In the market of electric motors, there are products designed for general purpose applications, and there are motors designed for specialized applications, such as automated guided vehicles (AGVs) or autonomous mobile robots (AMRs). While standard, general-purpose motors work for most applications such as factory automation, sometimes, it may help accelerate your design cycle by going with a motor system that already offers the features that you are planning to design into your machine. In this post, we will summarize some of these features.

Accurate Speed Regulation Prevents Weaving

|

Speed variation between the right and left wheels may cause a transport vehicle to weave and produce undesired results. With built-in speed regulation using hall-effect sensors, speed fluctuations can be minimized, which reduces the speed variation between wheels and prevents weaving. |

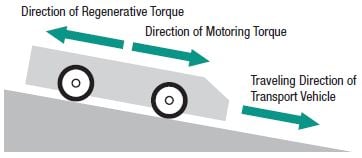

Vector Control for Ramp Operation

| In a ramp operation, speed regulation is difficult to maintain because gravity tends to overdrive the motor on its way down and increase its speed. By using the built-in “Vector Control", highly accurate torque control and load factor monitoring can maintain tight speed regulation, and back EMF can be controlled effectively. |  |

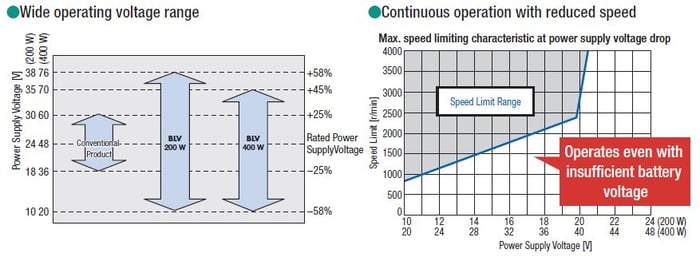

Low Battery Operation

For battery-operated vehicles, battery power is essential to keeping uptime. What happens if the battery is close to depleted? Motor systems that can work with low battery power can help maintain operational efficiency. For such systems, a wider range of input voltage can be accepted, and a limit is automatically placed on the speed range according to the input voltage. When the power supply voltage falls below a user-set level, a warning is output from the driver and can be used as an indication to return the vehicle back to a recharging station.

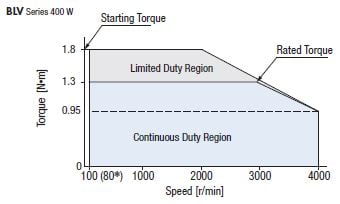

Constant Torque & Wide Speed Range

|

Built-in limits on speed and current prevent overheating for continuous duty operating cycles and maintain tight speed regulation even with fluctuations in load. |

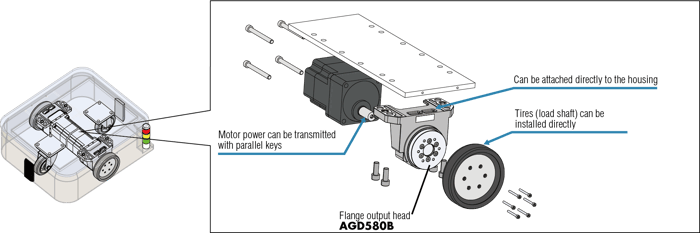

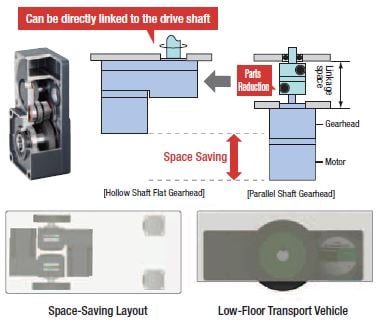

Unique Flat Hollow Shaft Gearhead Design with High Load to Motor Ratio

Here is how a parallel shaft brushless gear motor would be configured in the powertrain of an AGV. A flange drive adapter, AGD580B, will connect the gear motor shaft and the wheel/tire.

With the flat style hollow shaft gearhead, a smaller footprint can be realized by arranging the gearmotors in a space-saving configuration.

|

A unique flat style hollow shaft gearhead can be directly connected to the wheel shaft without a coupling, which helps minimize footprint for powertrain designs. |

|

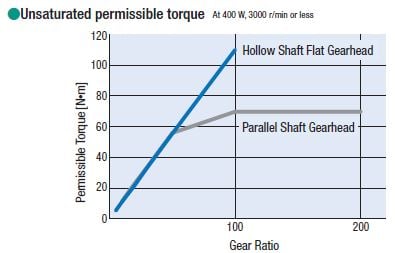

Larger diameter gears, larger diameter bearings, and rigid case design of the flat style gearhead help deliver high torque and high permissible radial load for high load capacity. Since there is no saturation of permissible torque, higher torque can be achieved than with a conventional parallel shaft gearhead. |

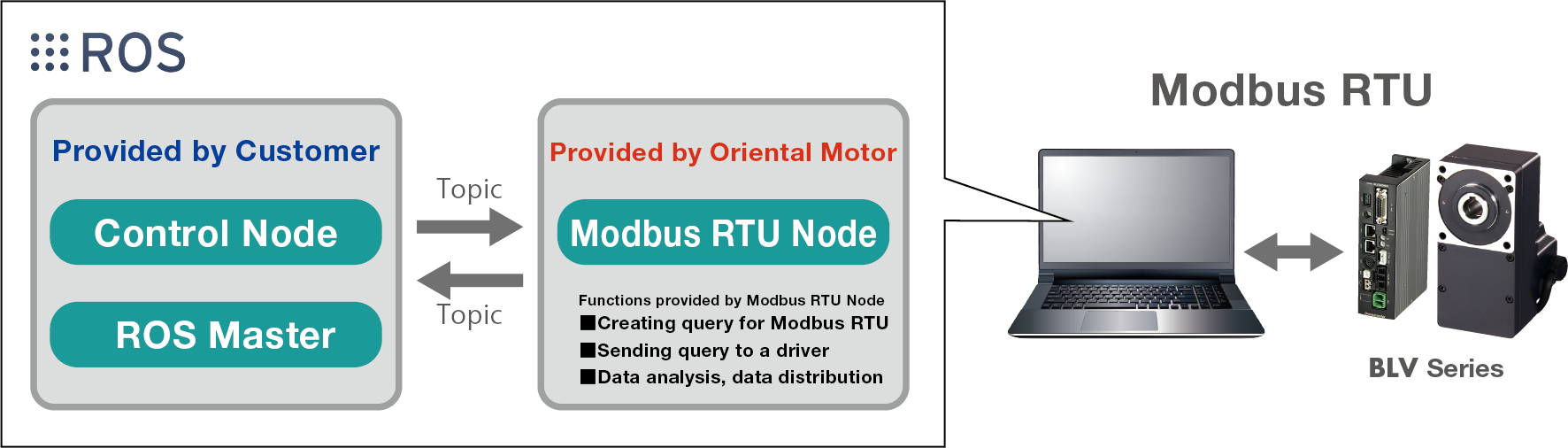

Network Capability

The standard built-in industrial communication protocol is Modbus RTU. For robot programming support with ROS (Robot Operating System), please comment below.

Other industrial communication protocols are also available, such as EtherNet/IP, EtherCAT, CC-Link, Mechatrolink II/III, and SSCNETIII/H. CANopen is available on the new BLV Series R Type.

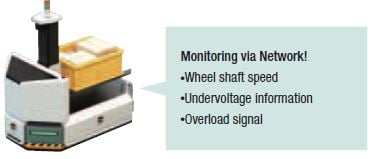

Wheel shaft speeds, load factor, and alarms from all axes of motion can be monitored in real-time by using software or network communication.

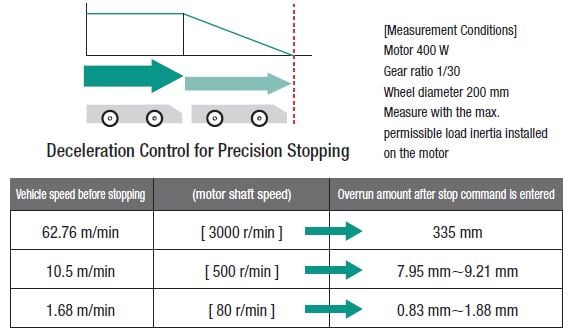

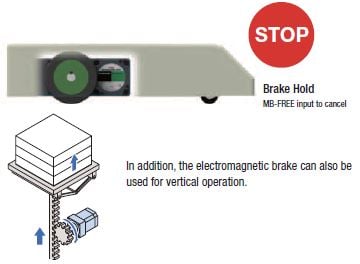

| TIP: Improve stop accuracy & avoid back-driving | ||||

|

NEW Product : BLV Series R Type

|

Oriental Motor's BLV Series R Type consists of a motor and dedicated compact driver for guaranteed specifications. Built-in features, such as torque limiting and wide battery voltage input are designed specifically for battery-operated vehicle applications. The BLV series R Type is offered at 1/4 and 1/2 HP; with rated torque up to 970 lb-in with the FR flat style gearhead. 60 and 400 W versions will be coming soon. For other product options, please contact our technical support engineers. |

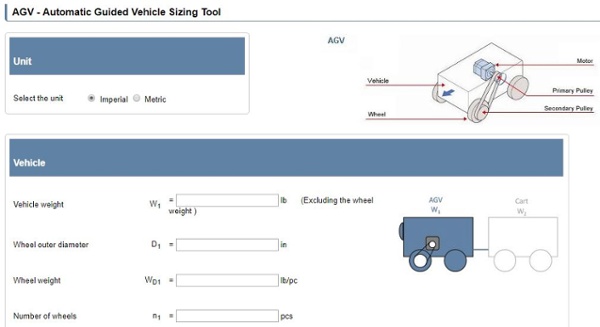

Ready to Size a Motor?

Please subscribe to receive new posts.