Increasing power efficiency and minimizing the carbon footprint is the trend these days. Do you know how to calculate CO2 emissions from your electric motors, and which types of motors emit less?

To calculate a motor's CO2 emissions, you need two things:

- Power consumption (kWh)

- CO2 base emission coefficient (kgCO2/kWh) [published by the electric power supplier]

With the following formula, you can estimate a motor's CO2 emissions

■Formula for Calculating a Motor’s CO2 Emissions

Motor’s CO2 emissions (kgCO2)

= Motor's power consumption (kWh)* × CO2 base emission coefficient (kgCO2⁄kWh)

*Please inquire with the nearest branch/sales office or our Customer Support Center about the power consumption of each combination of AC motor + general inverter and brushless motor.

Each electric power supplier’s CO2 base emission coefficient in the “List of base emission coefficients by electric power supplier” released by the Japanese Ministry of the Environment and Ministry of Economy, Trade, and Industry is used. For other countries, you'll have to find this information, but in the USA, power plants are required to provide this information.

| TIP: What is the CO2 base emission coefficient for power in the USA? |

|

In 2020, total U.S. electricity generation by the electric power industry of 4.01 trillion kilowatt hours (kWh) from all energy sources resulted in the emission of 1.55 billion metric tons—1.71 billion short tons—of carbon dioxide (CO2). This equaled about 0.85 pounds of CO2 emissions per kWh. This is an average value. For more specific CO2 base emissions coefficients, please refer to: |

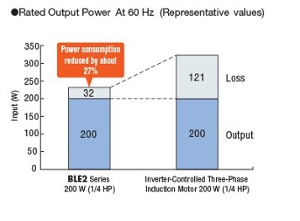

For a 200 W AC motor with an inverter (VFD), the annual CO2 emissions will be 521 kgCO2 according to the formula above.

Power consumption (1,109 kWh⁄year) × CO2 base emission coefficient (0.470 kgCO2⁄kWh)

= CO2 emissions (~521 kgCO2)

Conditions

-Calculated at 12 hours of drive time per day, 300 operating days per year, and a CO2 base emission coefficient of 0.470 kgCO2/kwh.

-Example is for a general 200 W output BH Series 3-phase AC induction motor with inverter (VFD).

However, if a higher efficiency is desired, a brushless (DC) motor should be considered.

If you use a brushless motor with the same output of 200 W, you can reduce the annual CO2 emissions to 386 kgCO2 under the following conditions. That's about 25% less than an AC motor.

Power consumption (821 kWh⁄year) × CO2 base emission coefficient (0.470 kgCO2⁄kWh)

= CO2 emissions (~386 kgCO2)

Conditions

-Calculated at 12 hours of drive time per day, 300 operating days per year, and a power–CO2 base emission coefficient of 0.470 kgCO2⁄kwh.

-Example is for a 200 W output BMU Series.

Here's a comparison:

|

Power Consumption

(kWh⁄year) |

CO2 Emissions

(kgCO2⁄year) |

|

|---|---|---|

|

AC Motor + Inverter

|

1,109

|

521

|

|

Brushless Motor + Driver

|

821

|

386

|

What does this mean?

What we're saying is that CO2 emissions can be reduced by 135 kgCO2 annually if a 200W AC motor and inverter (VFD) is replaced with a brushless motor system of equivalent specifications. 135 kgCO2⁄year is equivalent to one refrigerator’s annual CO2 emissions.*

*A 450 L capacity home refrigerator for 3 to 4 family members. (Source: The Ministry of the Environment’s Energy-Saving Product Replacement Navigation System Shinkyu-san)

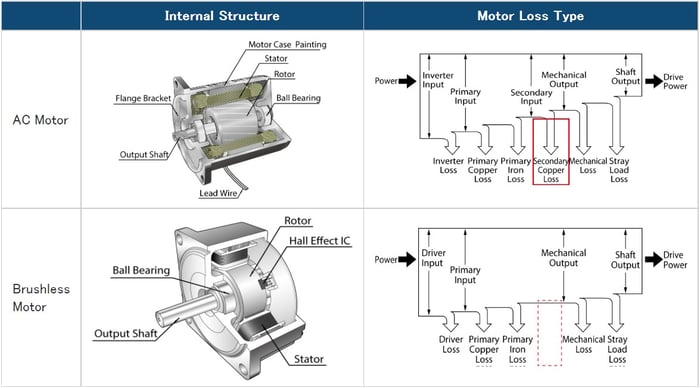

Why are brushless motors more efficient?

Brushless motors use permanent magnets to strengthen the magnetic flux, so their loss is lower than AC motors. The fact that they don't suffer from secondary copper loss is a major difference. That makes brushless motors highly efficient and allows them to use less power to do the same job. With higher efficiency, the motor size and weight can be reduced, which also contributes to the conservation of natural resources.

By the way, electrically commutated (EC) fans with onboard brushless motors can also contribute to energy savings. When comparing speed control technologies, brushless motors present many advantages over AC motors.

Takeaways |

|

To learn product tips that can help reduce energy consumption and carbon emissions, please visit our carbon neutrality page.

For a carbon neutrality consultation, please schedule a technical seminar.