CVD Series stepper drivers are the best choice for PKP Series high-torque stepper motors due to their unique abilities to reduce different types of motor vibrations and optimize performance.

One major reason why automation engineers should consider using both motors and drivers from the same manufacturer is that the manufacturer's unique knowledge of both products can be leveraged to enhance performance further. An example is the CVD Series driver's ability to suppress vibrations at high speeds caused by back EMF. This function is able to compensate current only when necessary, which is only possible with proprietary knowledge of the manufacturer's motor winding data.

Let me explain more.

Why Use CVD Series Stepper Drivers?

- Lowest vibration and noise

- Improved positioning accuracy

- High efficiency, compact 24 VDC design

- Highest torque with bipolar configuration

- Speed-torque characteristics are tested and guaranteed

- Many types and connector configurations to suit every need

- Save time from designing, building, and testing your own driver

Due to the CVD driver's compact design, efficiency characteristics, and unique vibration suppression functions. Oriental Motor considers the CVD drivers to be the industry's top performance driver for PKP Series high-torque stepper motors.

Various types of the CVD Series drivers accommodate different application requirements.

| Pulse Input Type | RS-485 Communication Type | S Type (Board Level Type) |

SC (Speed Control) Type |

Fully Closed Loop Control Type | 4-Axis, EtherCAT Type |

|

|

|

|

|

|

The CVD drivers were originally part of the older CVK Series, if anyone remembers. The CVK Series was originally introduced in 2014 and paired a PKP Series high-torque stepper motor with its dedicated CVD driver. The compact, board-level CVD Series drivers were specifically designed to optimize both the torque and accuracy of the PKP Series stepper motors, while minimizing various types of vibration and improving accuracy. The CVD drivers also work well with the other 4 lead wire stepper motors. Since then, the CVD drivers have expanded and evolved into the CVD Series.

In this article, I will briefly explain some of the unique features of the CVD Series drivers, introduce the various types of CVD Series drivers, and then go into some more details about each type of driver.

| Part I: Introduction of Main CVD Series Driver Features |

The CVD Series bipolar microstepping drivers offer several key features designed to optimize stepper motor performance in terms of torque, accuracy, and vibration resistance.

Multiple Functions to Minimize Different Types of Vibrations

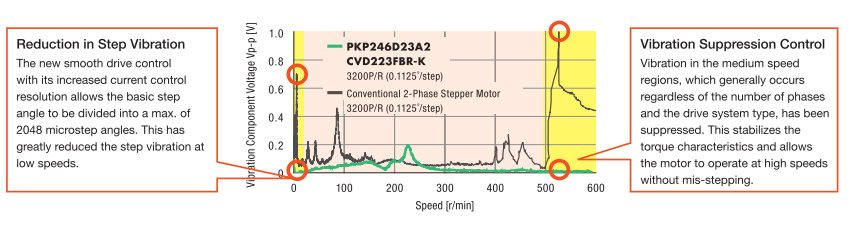

What sets the CVD drivers apart is that they offer multiple functions to minimize different types of vibration. The way it classifies vibration is by speed range. In the speed-torque curve below, you can observe the vibration level (measured as voltage) on the Y axis and the speed range on the X axis. The black line represents the performance of a conventional stepper motor and driver system. The green line represents the performance of a PKP Series stepper motor and a CVD driver.

With Oriental Motor's unique Smooth Drive algorithm, the driver automatically microsteps at 2048 steps per full step (full step = 1.8° for 2-phase or 0.72° for 5-phase). The benefit of this function is that the controller pulse output resolution can stay at full step while the motor operates with smooth, microstepping performance.

While the Smooth Drive function reduces vibrations for the entire speed range, it's especially effective at minimizing vibrations at low speeds caused by step movements (0~50 RPM). For the middle speed range (50~200 RPM) where vibrations are caused by resonance frequencies and torque ripples, the Current Phase Correction improves current waverforms and effectively minimizes vibrations. For the high speed range (500+ RPM) where vibrations can be caused by back EMF, the Vibration Suppression Control minimizes vibrations by compensating motor current with Field Weakening Control only when necessary, which is only possible by using proprietary motor winding data from the manufacturer.

The CVD drivers utilize a full-time digital current controller for easier current setting and improved current waveform control. In past driver designs, one current detector was used for all phases of the motor. In the CVD driver, each phase has its own current detector. This improves current uniformity in all motor phases, even when microstepping. By outputting a uniform, sinusoidal current waveform (sine wave drive), accuracy is improved when compared to trapezoidal wave drive.

|

The vibration characteristics do not change; even when step angles are changed. This is the result of the CVD Series drivers' unique current control capabilities. The graph below shows how the CVD driver minimizes all types of vibrations when all vibration suppression functions are active. 1. Low speed vibration occurs between 0~50 RPM |

|

In addition, many microstepping resolutions are available for you to choose from. For 2-phase stepper motors, 16 resolutions are available from 1.8° down to 0.00703125° (or 51,200 microsteps). For 2-phase stepper motors, 16 resolutions are available from 0.72° all the way down to 0.00288° (or 125,000 microsteps).

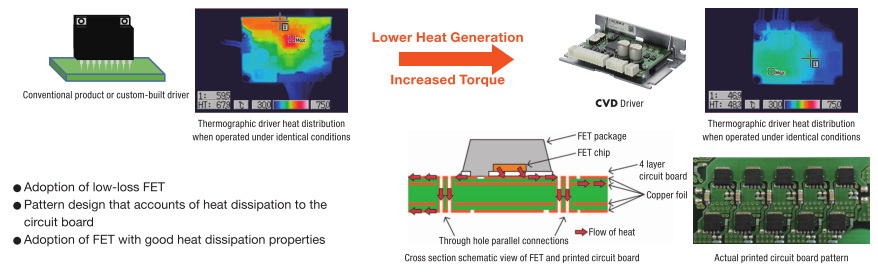

High Efficiency Design Makes Heat Sinks Optional

The CVD drivers utilize low-loss FETs and optimized tracing on the PCB for better heat dissipation. This improvement in efficiency makes the heat sink optional. A metal mounting plate is available for installation, not for its heat sink characteristics. Another benefit of this improved efficiency is its ability to output more current to the stepper motor and generate more torque.

| The CVD drivers have also improved their power efficiency. The highest power efficiency occurs at about 175 RPM. At this point, the power loss is 75% less than past, conventional designs. |  |

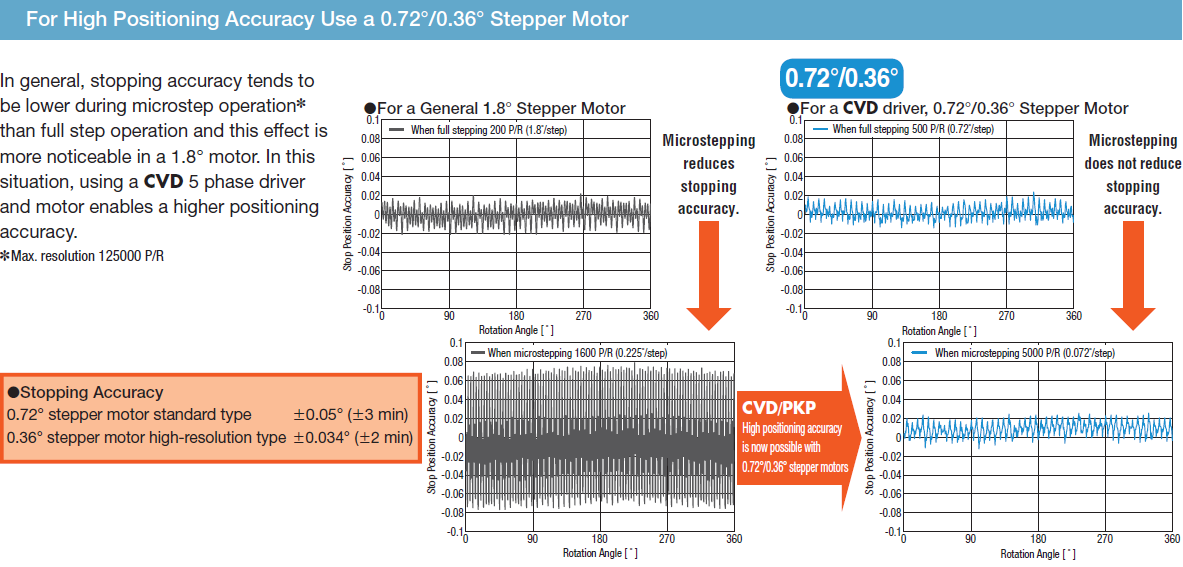

Improved Stopping Accuracy Even When Microstepping

Traditionally, using microstepping typically reduces stopping accuracy. However, with better current control from the CVD Series drivers, microstepping does not reduce stopping accuracy. For better positioning accuracy, 5-phase 0.72°/0.36° stepper motors are recommended instead of the typical 2-phase 1.8° stepper motors.

If even better accuracy is desired, high resolution type stepper motors are recommended. The stop accuracy specification is +/-0.05° for standard 1.8° and 0.72° PKP Series standard stepper motors and +/-0.034° for high resolution 0.9°/0.36° stepper motors. The higher tooth count from the high resolution stepper motors makes the motors more accurate.

| TIP | How to Choose Between 2-Phase and 5-Phase Stepper Motors? |

|

2-phase stepper motors are the most common while 5-phase stepper motors are designed for applications demanding less noise and vibration. For the same frame size and stack length, a 2-phase stepper motor with a CVD driver would offer more low speed torque, while a 5-phase stepper motor with a CVD driver would offer more high speed torque. With the CVD drivers, it's easy to upgrade from 2-phase to 5-phase since the driver size is the same. |

| Part II: CVD Driver Types + Configurations |

When we originally released the CVD drivers, only one type of driver was available - the Pulse Input Type. Over the years, we have expanded our product breadth to include 6 types and various configurations. For the most updated CVD drivers lineup, please refer to our website.

| Pulse Input Type | RS-485 Communication Type | S Type (Board Level Type) |

SC (Speed Control) Type |

Fully Closed Loop Control Type | 4-Axis, EtherCAT Type |

|

|

|

|

|

|

| Accepts pulse train from a host controller (2 or 5-phase) |

Accepts network commands from a host controller |

Designed to be installed on a PCB and compatible with SPI (2 or 5-phase) |

Built-in pulse generator for speed control (5-phase) | Closes the loop with high resolution encoders (5-phase) | 4-axis simultaneous synchronous or independent control (2 or 5-phase) |

|

Available Configurations |

|||||

|

|

|

|

|

|

These drivers are categorized as 2-phase, 5-phase, or multi-axis on our website. Please click for details about the types offered.

For more information about the various types of the CVD Series drivers, please read on.

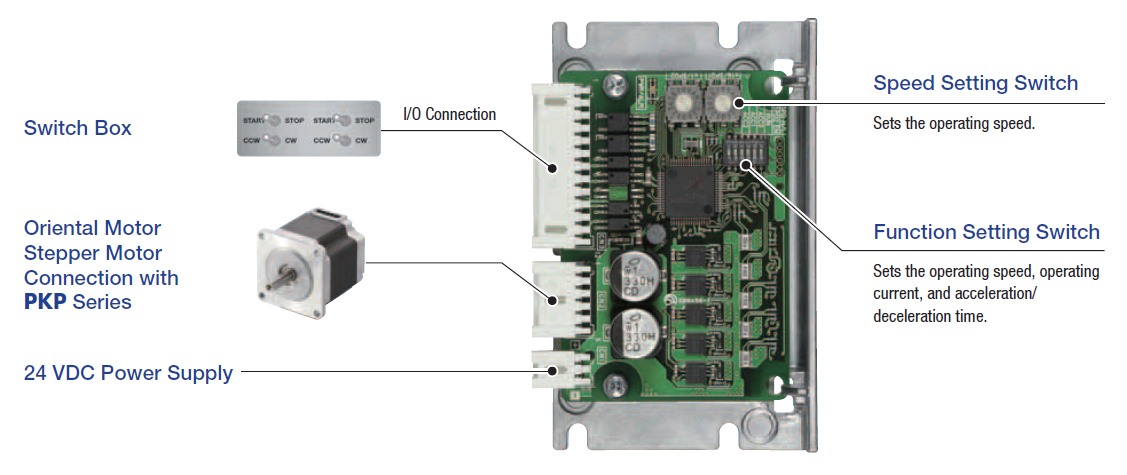

Pulse Input Type

The Pulse Input Type drivers are the most traditional type of CVD Series stepper drivers and are offered in either 2-phase or 5-phase versions. This driver accepts a pulse train signal from a host controller. The number of pulses equates to the distance that the stepper motor is moving in "steps", and the frequency of the pulses (in Hz, or pulses per second) determines the speed. The driver's I/O includes "pulse" and "direction" input designations when set in 1-pulse mode, and the same inputs switch to "CW" and "CCW" input designations when set to 2-pulse mode (according to user preference).

|

|

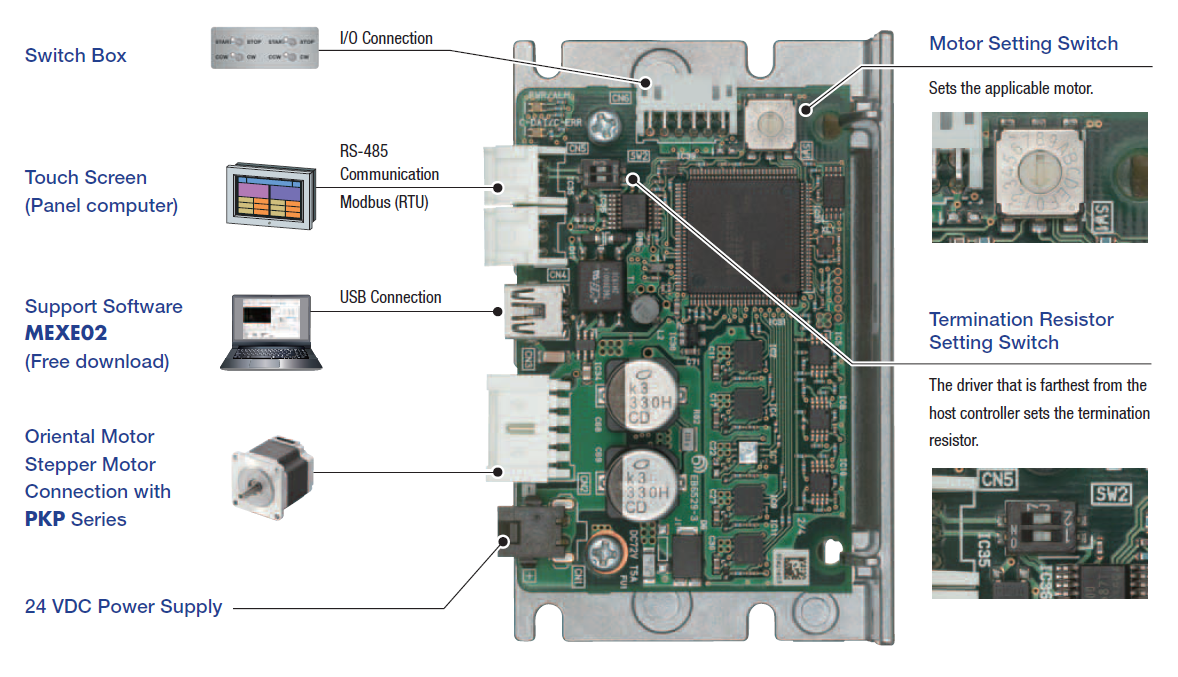

Here's a system configuration example.

There are three configurations available.

| Board Only | Mounting Plate with Standard Connectors* | Mounting Plate with Right-Angle Connectors |

|

|

|

| This configuration does not require a heat sink. The utilization of efficient components (low-loss FETs) and better heat dissipation properties (optimized tracing) helps make this possible. | This configuration is a version of the board only type with a mounting plate. The purpose of the mounting plate is for installation only. The standard connectors face up. | This configuration is a version of the mounting plate with standard connectors configuration except that the connectors are facing sideways instead of up. |

*The mounting plate with standard connectors configuration is not readily available in the USA at this time. Please ask our team if you're interested.

RS-485 Communication Type

This driver is the "smart" version of the CVD Series drivers and is offered in either 2-phase or 5-phase verions. The smarts come from its ability to store and execute stored motion profile data as well as communicate with the host controller through network commands and remote I/O. Since it offers built-in RS-485 communication compatibility, up to 31 drivers can be connected in a field network. Stored data and system parameters can be programmed with either the host controller through network commands or by using the MEXE02 support software. This driver is ideal for applications that require a built-in, programmable controller and network communication in the stepper drivers.

- For 2 or 5-phase PKP Series high torque stepper motors

- Built-in stored data controller and pulse generator

- 256 motion profiles can be stored

- RS-485 Communication - up to 31 drivers can be connected in an RS-485 network

- Stored motion profile data can be set by network commands or MEXE02 software

- Easily link complex motion profile sequences

- Both physical and remote I/O are available

The RS-485 communication type driver improves operation with network connectivity and GUI software and can minimize wiring since a network cable contains much fewer wires than an I/O cable. With an RS-485 network, up to 31 drivers can be connected together. With network I/O, communication between the host controller and driver can be improved without depending on physical I/O.

|

With the MEXE02 software and its stored data operations, such as jog, continuous, positioning, automatic sequential operations as well as its AREA outputs, complex motion sequences can be programmed in a short time even for non-programmers. |

| For example, the "Automatic Sequential Operation" method allows the user to "link" multiple motion profiles together as one long sequence with just one START signal. You can also set the acceleration/deceleration ramps and dwelling time...etc. |  |

There are two configurations available.

| Mounting Plate with Standard Connectors | Mounting Plate with Right-Angle Connectors |

|

|

| This configuration has the motor, power, and I/O connectors facing up. | This configuration has the motor, power, and I/O connectors facing sideways. |

S Type

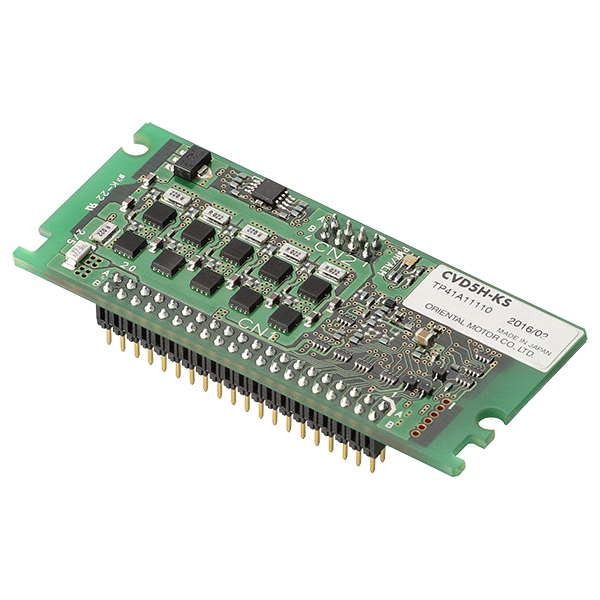

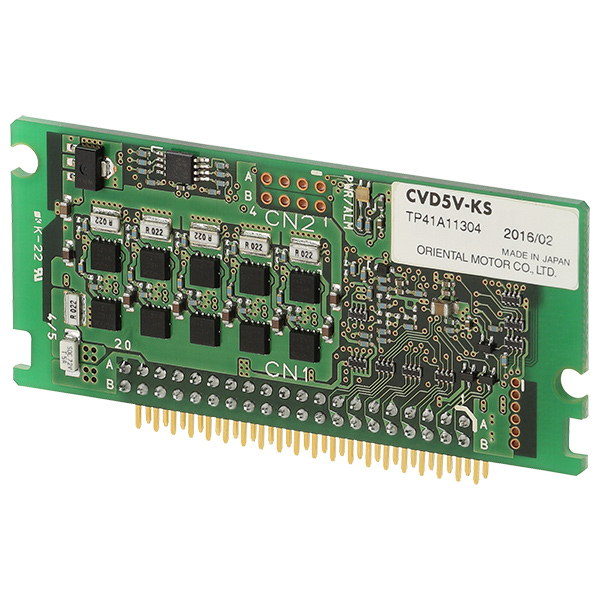

The S type CVD driver is different than the rest. The S type is the smallest of the CVD drivers and offers a shortcut for engineers who design their own drivers. There is a 2-phase version and a 5-phase version. These drivers are fully functional once installed and can be easily mounted on a bigger board for multi-axis control. Similar to other CVD drivers, the I/O pins can be configured vertically or horizontally to fit different board designs.

- For 2 or 5-phase PKP Series stepper motors

- 32 motor resolution settings (16 for 2-phase and 16 for 5-phase)

- Simply add an aluminum electrolytic capacitor on a motherboard

- The basic performance is the same as the CVK Series (PKP Series stepper motor + CVD Series driver)

- Contact sales for pricing and lead times

|

Since this product is designed for advanced users who design their own driver board, they are not available for sale online. A product consultation with our technical support engineers is recommended before purchase. |

There are two configurations available.

| Board Mounting Type Driver Module - Horizontal Mount | Board Mounting Type Driver Module - Vertical Mount |

|

|

| This configuration includes horizontal pins, which are oriented at a right angle from the board. | This configuration includes vertical pins, which are oriented in the same direction as the board. |

|

This table outlines the differences between the "H" and "V" driver variations. For both the "H" and "V" types, users can also select either I/O setting or SPI communication. The I/O setting driver is for users who simply want to use I/O to operate the driver. The SPI communication driver is for users who want to use board-level communication to set certain parameters. |

If you'd like to learn more about the S-type drivers, here's a white paper explaining their development.

SC Type

The "SC" in "SC Type" means "speed control". This is a simplified version of the CVD Series drivers with a built-in pulse generator designed to operate a stepper motor. This type of driver is ideal for basic speed control applications that require better stop accuracy and holding torque. At this time, the SC type driver is only available as a system package with 5-phase motors.

|

|

Here's a system configuration example.

|

This driver is best suited for applications that only require two stored speed settings. The benefits of this driver are reduced cost and minimized footprint. Although continuous operation is possible, the heat generated from the stepper motors may not be ideal when placed in close proximity to materials that can be adversely affected by heat, such as biological samples for research. Brushless motors should be used in those applications since they run cooler. There is only one SC Type driver configuration offered (with mounting plate). |

|

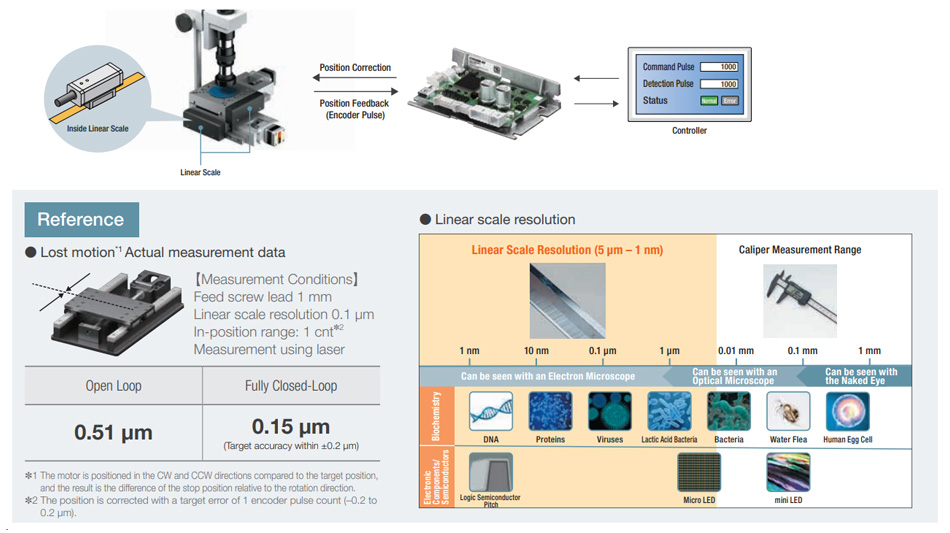

Fully Closed Control Type

The Fully Closed Control Type driver accepts high resolution rotary and linear encoders from 3rd party manufacturers, such as Mitutoyo, Heidenhain, Magnescale, and Renishaw. With a rotary encoder, it can accept a resolution range between 100 to 16,777,215 P/R. With a linear encoder, it can accept a resolution range between 1 to 50 nanometers. This driver also offers a built-in RS-485 communication interface and accepts Modbus RTU commands in a field network. This driver is ideal for engineers looking for the highest precision.

|

|

Here's a system configuration example.

By using a high resolution encoder to detect the mechanism position instead of the motor position, the highest precision can be achieved. Use the Fully Closed Control Type driver for applications that require the highest precision, such as chip inspection tables or microscopes. The accuracy, described in terms of lost motion measurements, can be improved from 0.51 micrometers to 0.15 micrometers.

There are two configurations available.

| Mounting Plate with Standard Connectors | Mounting Plate with Right-Angle Connectors |

|

|

| This configuration includes horizontal pins, which are oriented at a right angle from the board. | This configuration includes vertical pins, which are oriented in the same direction as the board. |

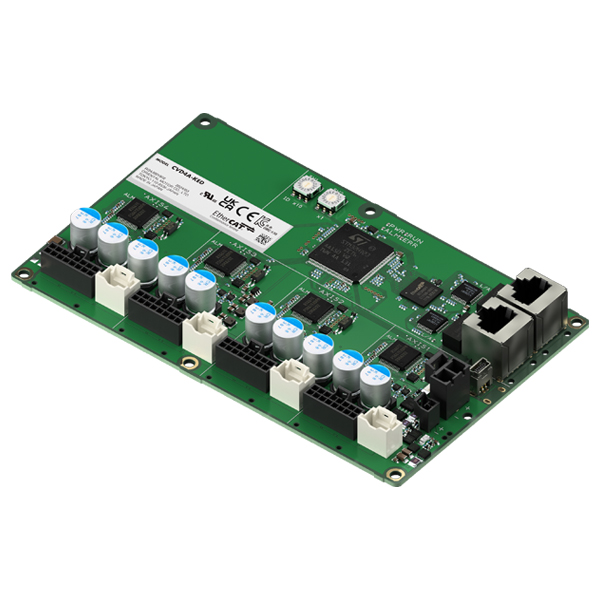

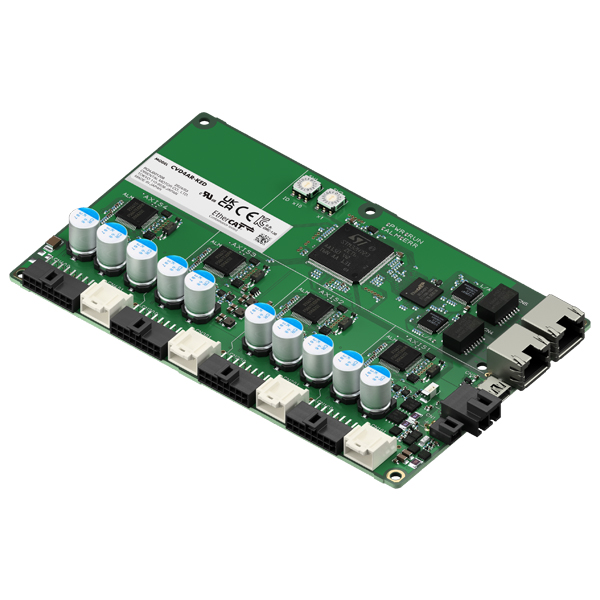

Multi-Axis Type (4-Axis)

This compact, multi-axis driver consolidates 4 drivers into one package. It features a lightweight design, reduces complicated wiring, and saves valuable space. Compatible with either 2-phase or 5-phase PKP Series stepper motors, as well as the DRL II Series compact linear actuators and DH Series rotary actuators, this driver is designed to be flexible and user-friendly. With built-in EtherCAT communication, compatibility with encoders, and automatic electromagnetic brake control, this is a complete driver that can save a lot of space and reduce costs.

- For 2 or 5-phase stepper motors

- No pulse generator needed

- Independent or synchronous operation for up to 4 motors

- Built-in EtherCAT communication

- Also compatible with rotary encoders

- Automatic electromagnetic brake control

- Daisy-chainable for even more axes

Here's a system configuration example containing both 2-phaes and 5-phase stepper motors as well as an encoder. 5-phase stepper motors are used on the syringe pumps for lower vibration and higher precision positioning capabilities, and 2-phase stepper motors are used for their high torque characteristics. EtherCAT communication ports allow communication with a host controller.

Here's another example showing a stepper motor, a geared stepper motor, an encoder type stepper motor, and a compact linear actuator controlled by the same CVD Series multi-axis type driver.

| These 4-axis drivers can also be daisy-chained to control more axes than just 4. Simply link the drivers by connecting an EtherCAT cable to the EtherCAT communication ports. |  |

There are two configurations available.

| Board Type with Standard Connectors | Board Type with Right Angle Connectors |

|

|

| This configuration includes vertical pins, which are oriented in the same direction as the board. | This configuration includes horizontal pins, which are oriented at a right angle to the board. |

Thanks for making it to the bottom of this article! This article is an updated version of an article that was originally published in August of 2021. For other ways to minimize stepper motor vibrations, please refer to this related blog article: Minimizing Stepper Motor Vibration

As always, our technical support engineers can help you find the best suitable driver(s) for your application or assist with motor selection.