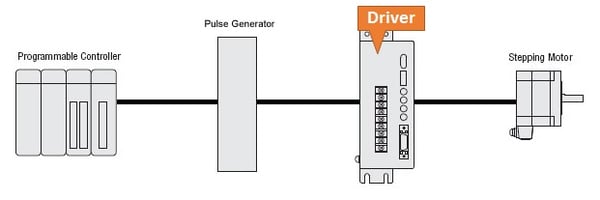

A driver is a must-have for any stepper motor. In a stepper motor system, a driver controls how the motor operates based on signals received from the controller. It is responsible for sending current through various phases in a stepper motor and also regulates the motor current (torque) and step resolution. With recent trends of minimizing machine footprint, finding space to install drivers could be challenging.

Standard Stepper Motor System Configuration

Oriental Motor is aware of this trend, and we have designed our standard stepper motor drivers with various mounting options to fit more machine designs.

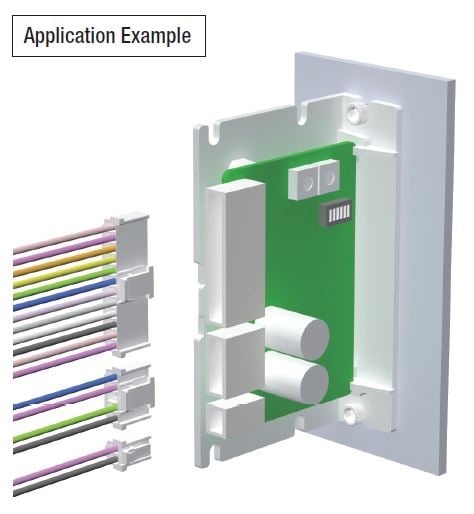

CHALLENGE 1 Mount a Driver Vertically with Horizontal Connections

SOLUTION Use a Right Angle Driver with Mounting Plate

With this type of driver, the connectors face outward (parallel to the circuit board). Mating connectors are provided. A right angle driver with Mounting plate can also be used with a driver cover and DIN rail mounting bracket.

|

Right Angle Driver with Mounting Plate

|

| Accessories |

| Driver Cover | DIN Rail Mounting Bracket |

|

|

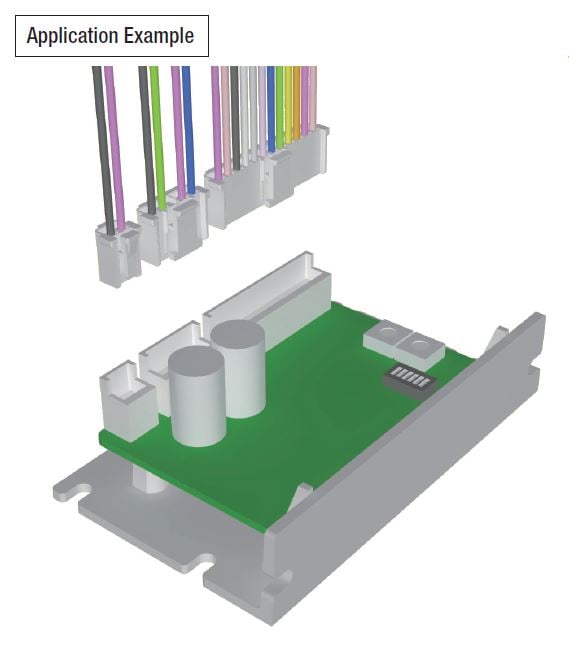

CHALLENGE 2 Mount a Driver Horizontally with Vertical Connections

SOLUTION Use a Driver with Mounting Plate

With this type of driver, the connector faces upward (perpendicular to the circuit board). Mating connectors are provided.

|

Driver with Mounting Plate

|

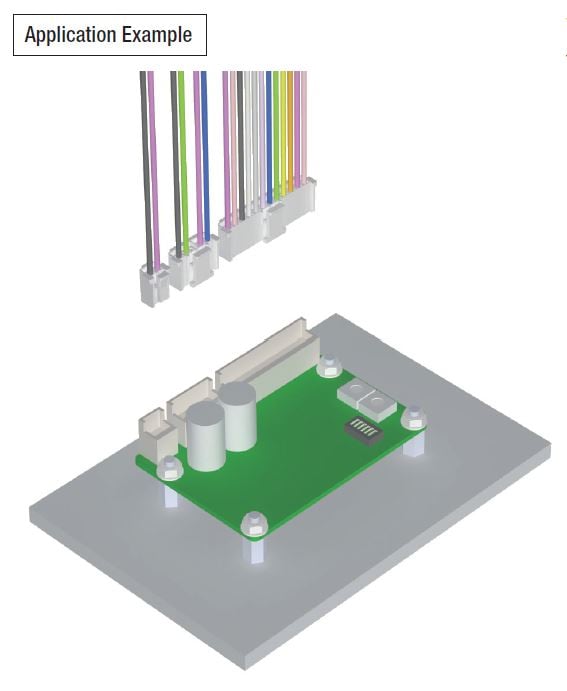

CHALLENGE 3 Mount a Driver Directly on a Metal Plate

SOLUTION Use a Driver without Mounting Plate

With this type of driver, the connectors face upward (perpendicular to the circuit board). Several design improvements, such as our high efficiency FETs, eliminate the requirement of a heat sink. Mating connectors are provided.

|

Driver without Mounting Plate

|

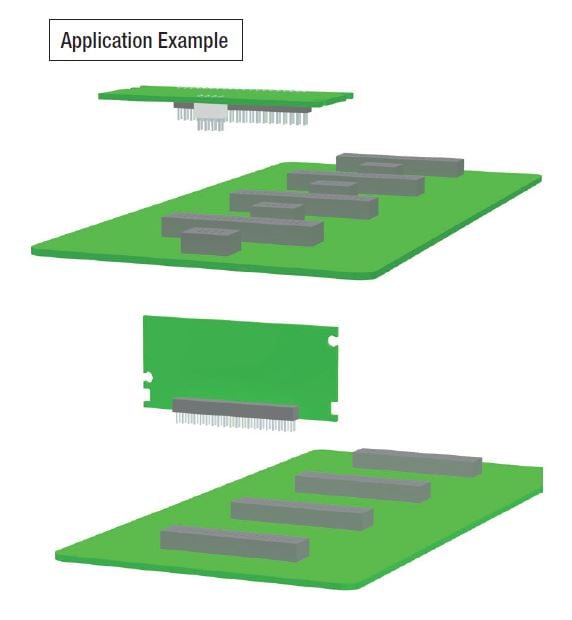

CHALLENGE 4 Mount a Driver Directly to a PCB

SOLUTION Use S-Type Drivers

This type of driver is great for engineers who prefer their own custom designs and can be installed right onto a printed circuit board (PCB) either by pin socket or direct solder. A vertical S-type and a horizontal S-type are available with either I/O only or SPI (Serial Peripheral Interface) bus communication.

|

S-Type Driver (available with SPI bus) |

To learn how our CVD drivers can help improve stepper motor performance, please click on your product of interest. Oriental Motor offers the CVD drivers for 2-phase or 5-phase stepper motors. While 2-phase is more common, 5-phase stepper motors can provide even lower vibration and noise.

|

|

For a brief introduction of the CVD driver's features, here's a quick video.

- Smooth Drive full-time advanced microstepping

- High efficiency FETs

- Digital current setting

- Vibration demonstration at resonant frequencies

- Mounting types

Need help selecting the right driver model for your stepper motor?