The significance of position control accuracy of motors varies depending on the application. For an AGV in a farm with DC motor-driven wheels, position control accuracy is probably not as crucial as a surgical robot where incisions are controlled by servo motors or stepper motors.

Having built a  ourselves, we now know how difficult it can be to understand all the different specifications and terminologies from each manufacturer. It's important to have a crystal clear understanding in order to avoid a potential disaster later.

ourselves, we now know how difficult it can be to understand all the different specifications and terminologies from each manufacturer. It's important to have a crystal clear understanding in order to avoid a potential disaster later.

In a motor and gearhead assembly product, "backlash" is listed as a standard specification to indicate mechanical precision of the transmission component between the motor and the load (ie: gears, lead/ball screws). However, certain type of gears do not have backlash, so another term, "lost motion", is used describe mechanical precision.

| What is Backlash? |

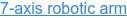

Backlash refers to the play, or clearance, between meshing gears inside the gearhead of a motor. Torsional backlash is measured when about 2% of the load torque is applied to the gear shaft. Backlash is necessary for several reasons. First, gear manufacturing is not 100% perfect. Manufacturing tolerances, bearing dimensions, thermal considerations, and other practical considerations contribute to this inaccuracy. Other reasons are to leave space for lubricants, reduce friction in the gears, and/or allow for metal expansion.

A gearhead, or gearbox, is used to both increase the torque (and inertial load) of a motor and reduce the speed. It contains a casing, gears, shafts, and bearings. When the gears mesh together, there is actually a tiny gap between the gears. This introduces inaccuracy in applications where precision is important because the load shaft can potentially move by the distance of the gap. It'll be much easier to understand by looking at the image below.

| Differences in Backlash |

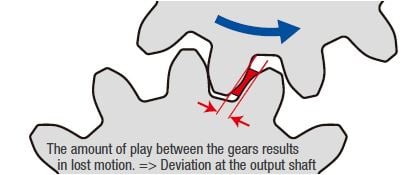

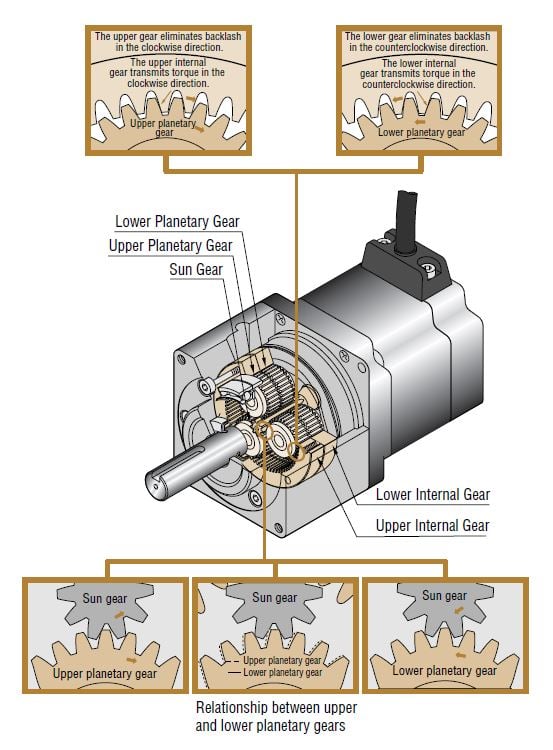

Different  exhibit different amounts of backlash based on its design. For example, spur gears exhibit the most backlash, planetary gearheads exhibit low backlash, and harmonic gearheads exhibit no backlash. A hybrid harmonic-planetary gearhead is also offered in the market.

exhibit different amounts of backlash based on its design. For example, spur gears exhibit the most backlash, planetary gearheads exhibit low backlash, and harmonic gearheads exhibit no backlash. A hybrid harmonic-planetary gearhead is also offered in the market.

Here's an example of how a planetary gear design minimizes backlash.

| Gear Type vs Backlash |

The table below lists most of our geared motors by gear type, features, torque, backlash, basic resolution and output shaft speed.

| Why is Backlash Important? |

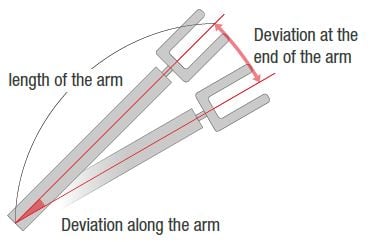

Backlash is measured in degrees or arc minutes or arc seconds. While this might seem like a very tiny value at the motor, this error can increase by distance in certain applications, such as robotic arms. The image below shows how the deviation differs from one end of the arm to the other.

| What is Lost Motion? |

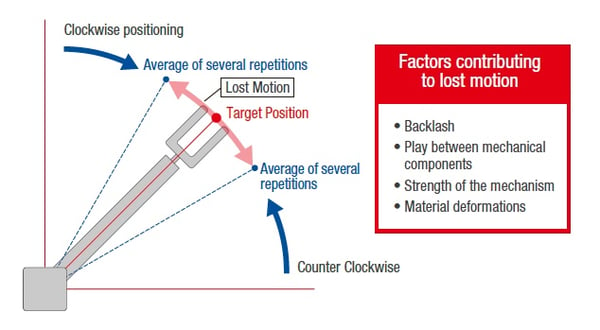

Lost motion is the largest deviation in a system when a position is repeatedly approached from the opposite direction while about 5% of the max torque is applied. Due to the applied torque, engineers often confuse lost motion with torsional backlash. Lost motion is a broader term. Factors contributing to lost motion are backlash, teeth play, strength of the transmission mechanism, and material deformations (mechanical hysteresis loss). Since the harmonic gear has no backlash, lost motion is used as a reference for gear accuracy.

| Any Ways to Eliminate Backlash? |

It depends. The easy way would be to purchase a harmonic geared stepper motor (no backlash).

| TIP: an old trick | ||

Let's say that the top gear is driven by the motor, and the bottom gear is driving the load. To avoid the red part in the image above, the trick is to keep the top gear (and the motor) rotating clockwise (opposite of blue arrow). As long as the top gear and the bottom gear are always in contact, the red area is avoided, and backlash is eliminated. However, this only works for unidirectional applications. For bidirectional applications, the trick would be to keep approaching your target position from the same direction every time. Let's take a simple application for example. Your motor is performing a back and forth motion between 0 and 90 degrees. However, the backlash from a bidirectional motion is causing the load to stop just outside the accuracy tolerance when you move back to home (0 degrees). Next time, perform the same two moves, but when you move back to the home position, intentionally pass the home position just by a bit, stop, then approach it again (from the same direction as the 90 degree move). This way, the motor always approaches a target position in the same direction. The backlash is eliminated. However, this only works for applications where there's extra dwell time in between moves. |

| Summary |

Backlash is the play, or clearance, between gear teeth in gearheads. In other words, backlash is the movement in the gear shaft while the motor shaft is fixed. In mathematical terms, it is the width of the space between meshing gears minus the width of one gear tooth.

Lost motion is the total displacement that occurs in both directions when a load torque corresponding to about 5% of the permissible torque is applied to the gearhead output shaft. In other words, lost motion is the loss of motion in the gear shaft while the motor shaft is moving and includes backlash and gear hysteresis loss.

Backlash is a component of lost motion.

For applications that require the utmost position control accuracy, harmonic gearheads are recommended. If the application can accept a little backlash, harmonic-planetary or planetary gearheads are recommended. For general purpose applications or unidirectional applications, spur or taper-hobbed may suffice. Of course, higher precision costs more, so decide with your budget in mind.

Remember that inaccuracies in motion control are a combination of all the individual components in the system. One must also consider the precision of the other components in addition to the motor and gearhead.

Thanks for reading. How do you eliminate backlash? Please comment!