Proper grounding is necessary for electrical devices for different reasons, but why do we do it?

My first bad experience with electricity was an electric shock from an AC wall outlet. I don't remember much since this happened when I was a child, but I do remember touching the outlet and my body vibrating for a second. Needless to say, I stayed away from electricity until I had to wire up motors to simulate real customer scenarios in the field. Now that I think about it, that wall outlet was most likely not grounded properly.

Why ground?

- Prevent damage or injury

- Protection against electrical overload

- Stabilize voltage levels

Proper grounding can prevent electric shock for people who work around electricity. Electricity always travels through the easiest path from voltage to ground.

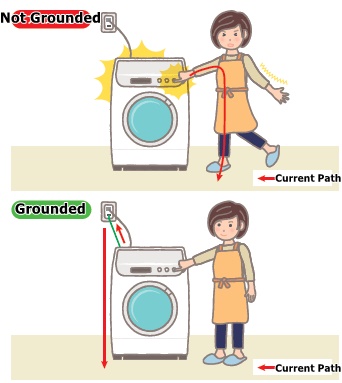

The washing machine example below illustrates the concept of current path in an appliance that is not grounded vs grounded.

When the appliance is not grounded, the leakage current generated from within the appliance becomes a potential that is just looking for a path to ground. As soon as a human touches the appliance and has a clear path to ground, the human becomes the grounding wire, and current will travel through the human body then to ground. I don't know if you can tell, but she does not have a happy face.

When an appliance is grounded, the leakage current now has a less resistant path to ground than the human body, so the leakage current skips the human body and travels through the grounding wire in the AC plug, which has its own path to ground. Now she has a happy face.

Why do we need to ground motors?

Well for one, grounding is required for pretty much all electric motors. The National Electrical Code (NEC), section 430-L, defines the motor grounding conditions.

Electricity flow through the motor's windings, which are typically insulated from other parts of the motor. A potentially dangerous situation occurs when the insulation fails. At this point, the motor frame can become a conductor at the same voltage input to the motor. Any one touching that motor frame and a grounded surface can be subject to injury or worse. Once the motor is grounded, the excess voltage will have a safe path to ground.

An electric shock, or worse, electrocution, can happen if the motor's PE terminal is not grounded. A current as little as 0.1 to 0.2 amp can potentially kill a human.

|

Have you wondered why this sign always say

|

Let's review the roles of the three usual suspects of Ohm's Law, V, I, and R, in an electrocution. Voltage is the potential energy in the form of electrical charge, current is the output in the form of a flow of electrical charge defined in amperes, and resistance resists the flow of current. In actuality, current is the most dangerous of the three. However, the sign says "high voltage" because without high voltage "potential", there wouldn't be enough current to be dangerous. |

The threat of AC current varies widely by its frequency, whereas DC simply becomes more dangerous as the voltage and current levels increase. Here's a table from OSHA which describes the potential damages.

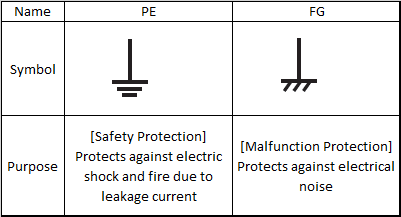

What do "PE" and "FG" mean?

PE - Protective Earth

In the UK, they call it "earthing". In the US, we call it "grounding". They mean the same electrical 0v potential. The purpose of PE is to protect against electric shock and fire due to leakage current.

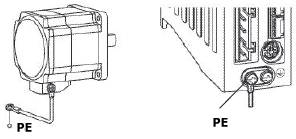

While motor grounding used to take place with one of the four bolts or screws, dedicated screw terminals are offered now for easier implementation.

FG - Frame Ground

This is also known as the "chassis ground". The purpose of FG is to protect against electrical noise, which can distort signals and cause malfunctions.

| Note: This post does not discuss signal ground, which is the third type of grounding typically confused with protective earth and frame grounding. For information about signal ground, please refer to this article, Ground rules: earth, chassis, and signal ground from Analog IC Tips. |

PE terminal examples

The PE terminal can be a screw terminal on a motor or a screw terminal on a driver. Both the motor and driver need to be grounded.

Examples: PE terminals

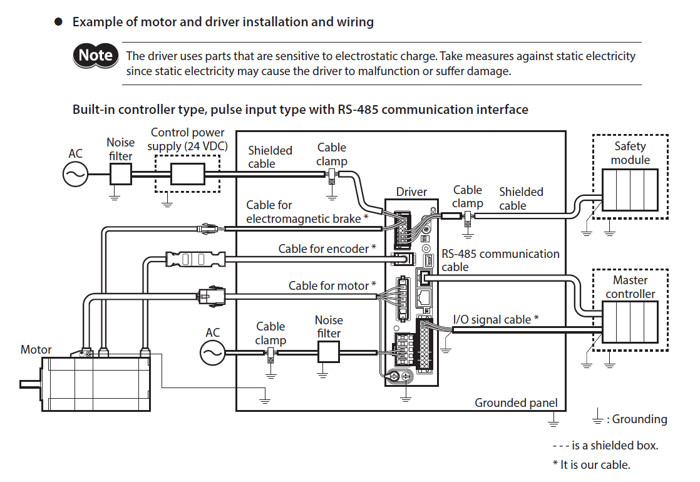

This motor and driver installation and wiring diagram example below shows where PE grounding is necessary in a stepper motor system configuration.

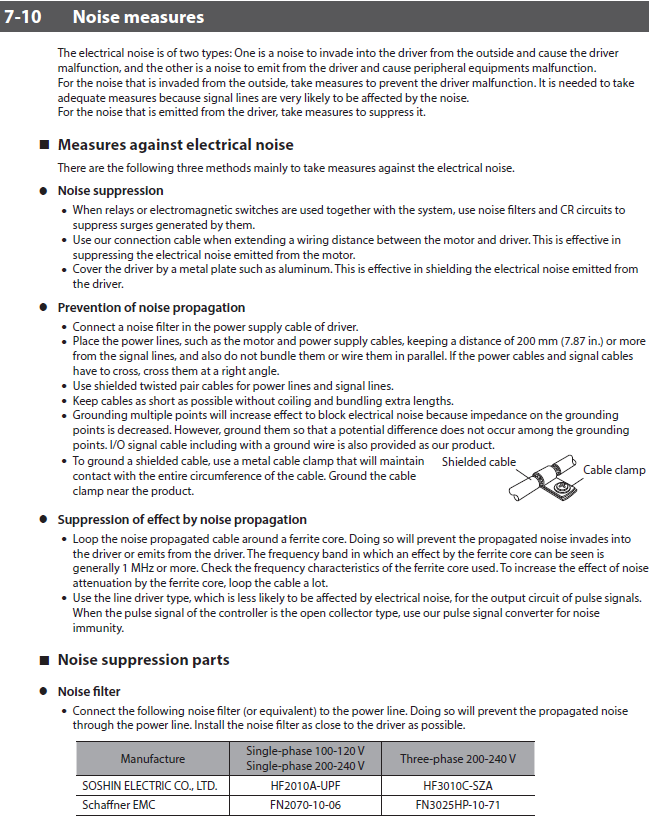

For measures against electrical noise, including FG grounding, we provide the following information in our manuals.

| TIP: Use thicker and shorter grounding wire |

| When wiring the ground wire to ground, use a thicker and shorter wire. This decreases the resistance of the wire, so it's easier for current to flow through. |

For instructions on grounding your specific Oriental Motor product, please check with the operator manuals, or ask our helpful technical support engineers. The easiest way to find a product's operating manual is to perform a part number search. Need help? Please contact us by phone, e-mail, or chat.

Please subscribe to receive notifications about new posts.