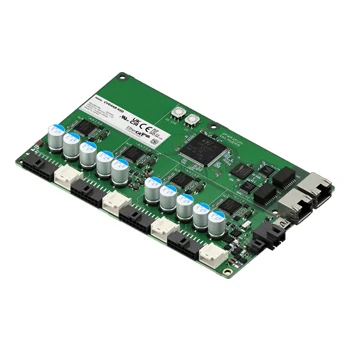

The CVD Series EtherCAT-compatible multi-axis driver combines 4 stepper motor drive circuits into one package that saves space and consolidates wiring. Furthermore, by using EtherCAT network commands and remote I/O instead of hard-wired pulse and direction signals and physical I/O, wiring can be minimized even more. Cables take up additional space and cost money. By consolidating drive circuits and eliminating cables, the machine can be more compact than past designs.

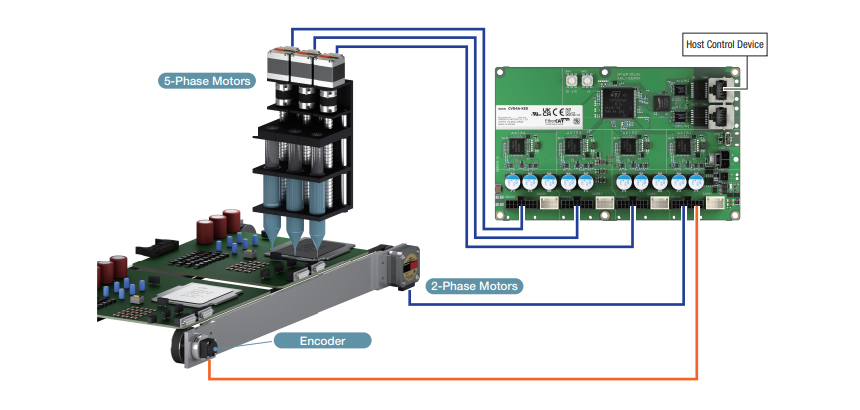

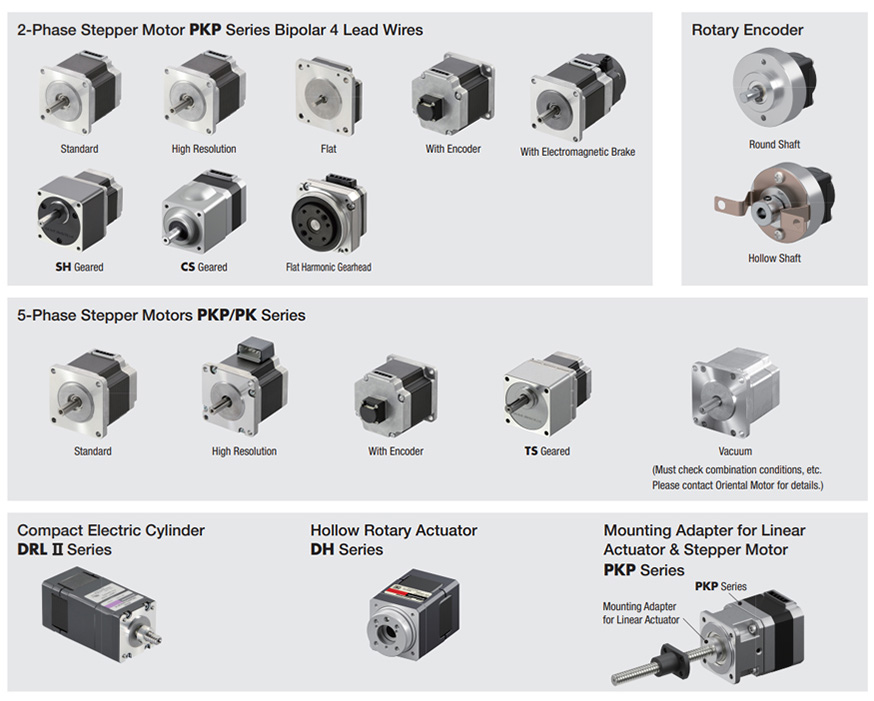

With built-in compatibility for both 2-phase and 5-phase PKP Series high-torque stepper motors, a wide lineup of our stepper motors is available for product selection, and existing PKP Series stepper motors can still be used for the next-gen design.

- Consolidates wiring and control for up to 4 stepper motors

Up to 4 PKP Series high-torque stepper motors can be controlled by a single 4-axis driver while wiring for power supply and communication is consolidated. It also offers compatibility for both 2-phase and 5-phase stepper motors as well as encoder inputs for stepper motors with built-in encoders.

- Compatible with either 2-phase or 5-phase stepper motors

The multi-axis driver is compatible with 2-phase and 5-phase stepper motors, which allows the machine manufacturer to use existing 2-phase and 5-phase PKP Series stepper motors without changing the design. In the future, the machine manufacturer can also use other types of motors from the PKP Series lineup without changing the driver.

Compatibility:

- PKP Series 2-phase bipolar stepper motors rated between 0.5~2.8 A/phase

- PKP Series 5-phase new pentagon bipolar stepper motors rated between 0.35~2.4 A/phase

- DRL II Series compact electric cylinders (5-phase)

- DH Series hollow rotary actuators (5-phase)

- Stepper motor linear actuator (5-phase)

|

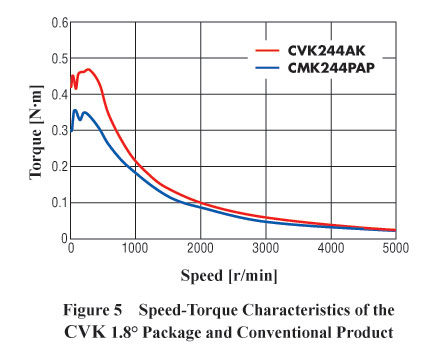

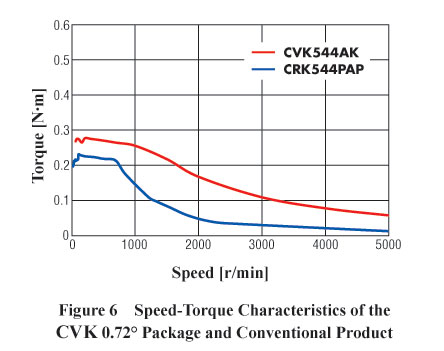

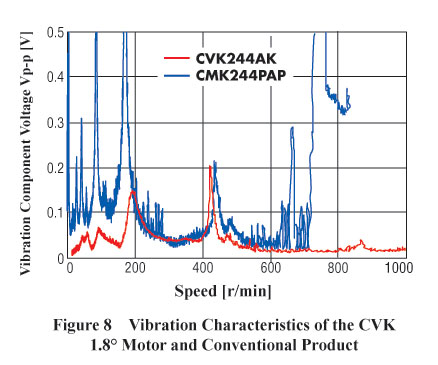

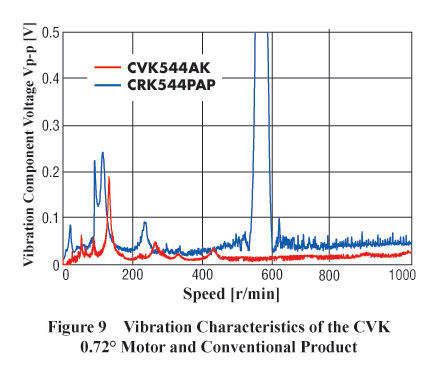

TIP: Choose a 2-phase stepper motor for high torque, mid speed performance, or a 5-phase stepper motor for low vibration, high speed performance. Performance and vibration comparison data are available below. Hint: notice that at 2,000 RPM, the 2-phase motor [CVK244AK] offers more torque, but at 3,000 RPM, the 5-phase motor [CVK544AK] offers more torque.

More info: https://www.orientalmotor.com/stepper-motors/technology/stepper-motors-and-driver-cvk.html |

- EtherCAT communication enables synchronous operation

Enable real-time synchronous operation by setting up a deterministic EtherCAT industrial Ethernet fieldbus network. In the example below, we show a configuration with a standard flat connector type stepper motor, a geared type stepper motor, an encoder type stepper motor, and a compact linear actuator. Through EtherCAT network commands, the host controller can command the stepper motors to move or monitor specific statuses with just a few wires.

Dimensions of this multi-axis driver are 160 mm x 100 mm, and it only weighs 110 g.

The multi-axis driver can also be daisy-chained, making it even easier to add more axes quickly by simply connecting additional drivers with EtherCAT cables.

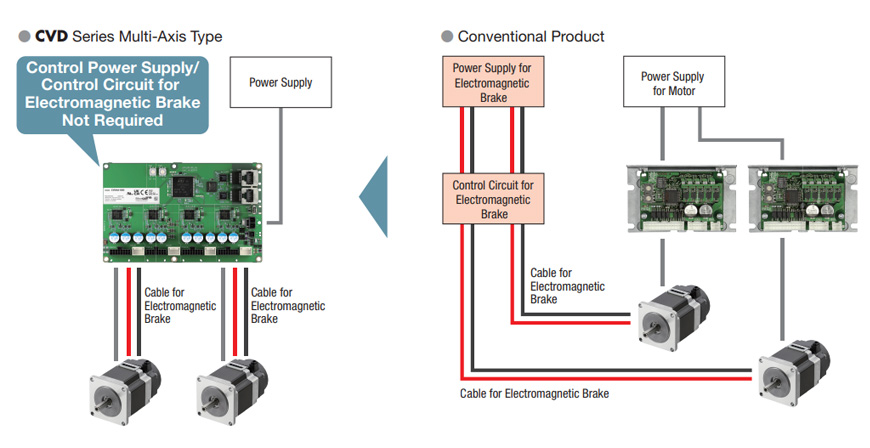

- Automatic control of electromagnetic brakes

This multi-axis driver also offers built-in control for electromagnetic brakes. No additional electromagnetic brake control circuits are necessary, which reduces the time required for design, development, and wiring. With another multi-axis driver, additional control circuits are necessary to engage the brake at the right time.

- Compatible with encoders

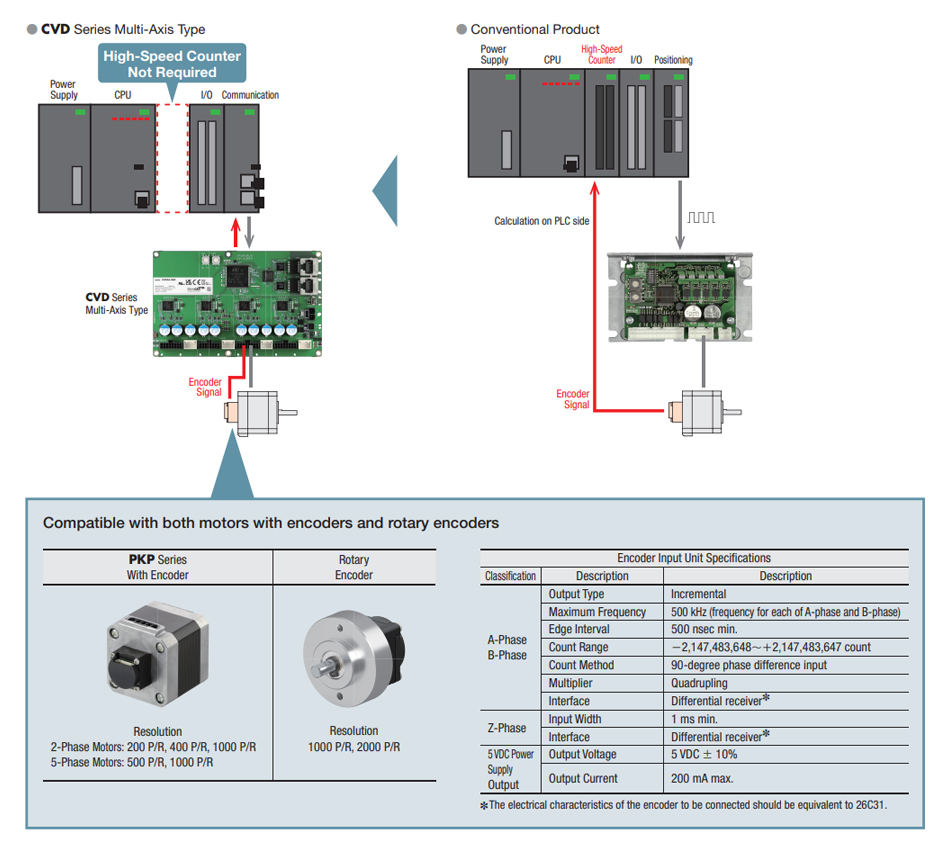

The multi-axis driver is also compatible with encoders and can reduce the burden on the host controller, so the machine manufacturer can close the loop if they want to offer a more reliable version of the machine. The multi-axis driver can connect to encoders directly and detect position deviations without relying on the host controller. The encoder position can be accessed by network command. Traditionally, encoders are connected to a high-speed pulse counter at the host controller.

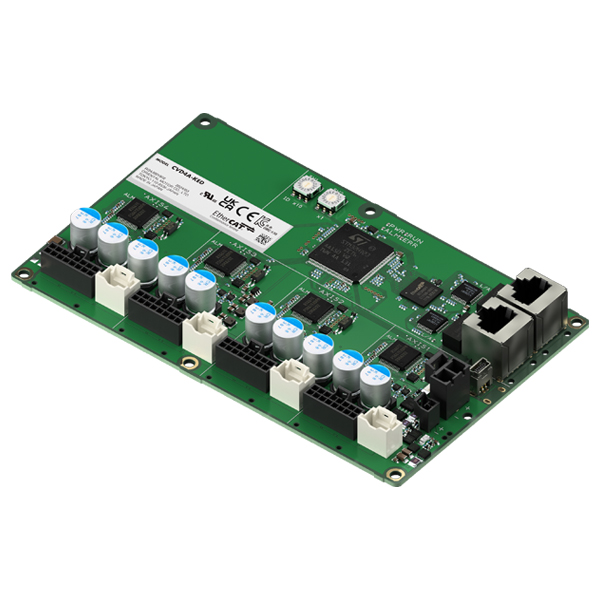

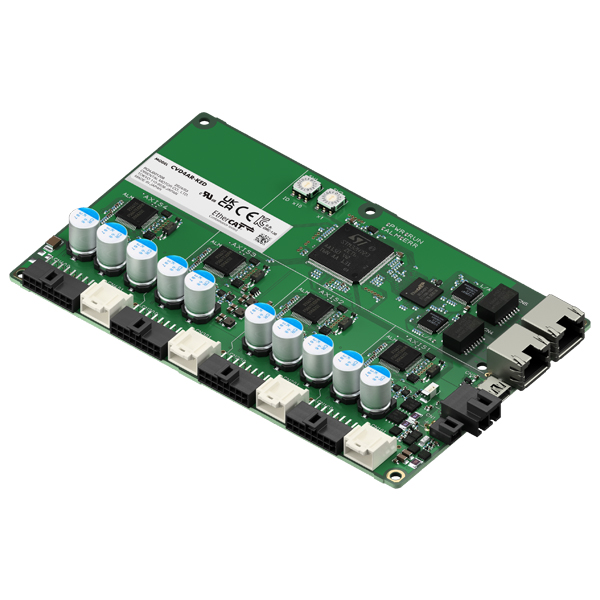

- Parallel or right-angle connector configurations

Parallel or right-angle connector configurations are available. For up to 4 axes of motion, the parallel connector type driver can be sufficient. The right-angle connector type driver can be installed with several more units placed closely side by side, so it's better for applications requiring more than 4 axes of motion. Choose the one that makes the most sense to you.

| Parallel Connectors | Right-Angle Connectors |

|

|

|

|

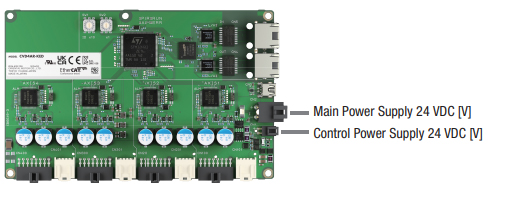

- Designed for Safe, Low Voltage DC Power Supply

The driver's main and control power supply are both rated for 24 VDC, which is considered to be a low voltage and therefore highly safe and universal for global usage. This is the same for most CVD Series stepper drivers.

In the following video, an application example of an automated chip inspection process is shown with 4 independent axes of motion. A CVD Series EtherCAT-compatible multi-axis driver can be used to control all axes.

- X-axis of the precision stage: PKP Series stepper motor

- Y-axis of the precision stage: PKP Series stepper motor

- Z-axis movement of the vacuum gripper: DR Series compact linear actuator

- Theta axis of the vacuum gripper: DH Series hollow rotary actuator

Click to learn more about the features of our multi-axis EtherCAT driver

As always, our helpful technical support engineers are also ready to answer your questions.