Are you using motors for a start/stop conveyor or similar application? While AC motors are a common choice for conveyors, there is a unique speed control motor solution available that could improve stop accuracy as well as reduce footprint and cost of machine designs.

|

Improve stop accuracy and minimize footprint |

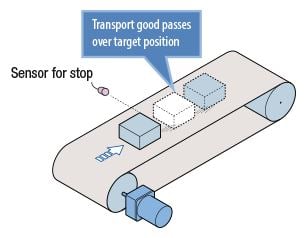

First, let's understand the main challenge of a start/stop conveyor, which is maintaining a good, repetitive stop accuracy. In this application example, we use a material handling conveyor that moves when there is no load detected by the sensor, and stops when there's a load detected. This type of conveyor is frequently integrated with a robotic arm for a pass/reject quality control process, or a pick and place process.

Application Example: Start/Stop Conveyor with Sensor Control

- Conveyor moves when there is no load detected by the sensor.

- Conveyor stops when load is detected by the sensor.

|

A motor with inconsistent stop accuracy or excessive overrun could cause the robotic arm to pick up the wrong product. With AC motors, a difference in inertial load can also change its overrun characteristics, which requires physically moving the sensor location to adjust for position accuracy. |

|

|

|

Stepper motors aren't usually considered for speed control, but its high responsiveness can improve stop accuracy for low speed or frequent start/stop applications. Unlike AC motors, the difference in inertial load will not change the stopping characteristics. |

Here we compare the overrun characteristics of AC motors vs stepper motors.

|

Use a stepper motor with a simplified speed control driver |

Oriental Motor's CVK-SC Series uniquely combines a high torque  PKP stepper motor with a simplified version of the compact CVD bipolar microstepping driver that operates easily like other speed controllers. The CVD speed control driver does not require an external pulse generator. Therefore it can also help minimize footprint.

PKP stepper motor with a simplified version of the compact CVD bipolar microstepping driver that operates easily like other speed controllers. The CVD speed control driver does not require an external pulse generator. Therefore it can also help minimize footprint.

2 stored speed settings (0.02~600 RPM) and acceleration/deceleration rate (0~3 seconds) can be set with rotary and dip switches. The stepper motor offers better response and stopping accuracy than AC or brushless motors and provides holding torque while the driver's  function ensures low vibration performance. Due to the efficient design of the driver, the CVK-SC Series can run continuous duty cycles without overheating (at full current setting in most cases).

function ensures low vibration performance. Due to the efficient design of the driver, the CVK-SC Series can run continuous duty cycles without overheating (at full current setting in most cases).

In summary, the high torque density of stepper motors and the compact, standalone design of a speed control type driver can help reduce footprint and simplify designs for low speed applications. Please consult with our  to see if it's the right solution for you.

to see if it's the right solution for you.

|

Notable Features:

|

|

Watch how easy it is to operate a CVK-SC Series motor and driver!

|

Among many improvements in design, the minimized air gap, optimized stator/rotor ratio, and high density winding of the stepper motor increases torque while the driver's Smooth Drive and improved current control features minimize vibration and increase accuracy. Furthermore, the efficient design of the dedicated drivers allow continuous duty operation without the need for heat sinks. |

Interested in receiving new posts? Please subscribe at the top of this page.