The differences between single-phase and three-phase AC induction motors don't stop with the input power supply. There are a few reasons why three-phase AC induction motors work better for an instantaneous forward/reverse operation.

What is an Instantaneous Forward/Reverse Operation?

An instantaneous forward/reverse operation describes a motor that is rotating back and forth between two positions repeatedly. An application example could be a connector test fixture that inserts and retracts the connector to test its reliability. This can be done with AC motors, brushless motors, servo motors, or stepper motors. They all can reverse direction. The deciding factor is how fast and how accurately you want the motor to stop when commanded to stop.

What Makes K2S SeriesThree-Phase Motors Better for Instantaneous Forward/Reverse Operation?

✔️Balanced Windings

First, the winding design is different. The electrical specifications (resistance) of the primary and secondary windings inside the motor are more balanced with three-phase motors than with single-phase motors. Please see the table below.

| Power Supply (VAC) | Motor | Primary Winding | Secondary Winding | |

| Phase U (Ohms) | Phase V (Ohms) | Phase W (Ohms) | ||

| Single-Phase 200/220/230 | 4IK25A-CW | 157.6 | 157.1 | n/a |

| Three-Phase 200/220/230 | 4IK25A-SW | 179.9 | 179.9 | 179.9 |

✔️Better Speed-Torque Performance

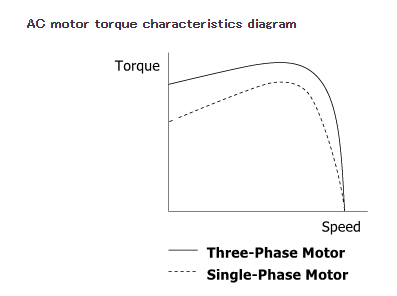

Different winding specifications affect the motor's speed-torque characteristics. In the image below, we compare the speed-torque curves for a single-phase motor and a three-phase motor. The three-phase motor shows better torque characteristics throughout the entire speed range.

Also, by offering more torque in the lower speed region, three-phase motors offer better starting torque and are better for instantaneous forward/reverse operation. When a single-phase motor stops and reverses, the lower torque means that the motor will decelerate slower to zero RPM, then accelerate slower to its rated speed. When a three-phase motor stops and reverses, it will decelerate then accelerate up to its rated speed faster.

✔️Less Overrun

FYI single-phase motors do not stop immediately. Unless they are used with some type of friction, electromagnetic, clutch brake mechanism, or electronic brake pack, they will coast to a stop. The coasting distance, or overrun, depends on friction and inertial load, but it can be as much as 30 revolutions (at the motor shaft; divisible by gear ratio). This overrun doesn't work well with the "instantaneous" part of an instantaneous forward/reverse operation since the motor now needs time to accelerate up to its rated speed every single time it starts. If you switch direction too quickly without waiting for the motor to decelerate to a stop, the motor may keep rotating in the same direction.

The overrun is the same between single-phase and three-phase AC induction motors once power is removed, although the higher starting torque from three-phase motors makes them ideal for instantaneous forward/reverse operations.

| TIP #1: Stop a three-phase motor first before reversing direction to prevent gear damage |

|

If you want the motor to last, here are two reasons why you should stop the motor first before reversing its direction. The best method is to allow the motor to come to a complete stop before switching direction. Otherwise, testing is recommended to prevent gear damage. In some cases, the gears in a geared motor can be damaged due to impact at the moment of reversal. If the direction of the motor is switched too quickly, the load may still keep rotating in the same direction, but the motor is actually trying to rotate in the opposite direction. Since torque works in both directions, the gears may be damaged. Minimizing impact forces for the gears inside the motor's gearhead can prolong its life. |

|

TIP #2: Use an electromagnetic switch that offers an interlock structure to prevent the risk of a power short circuit |

|

The internal wiring of the windings inside a single-phase motor and a three-phase motor is different. Therefore, the external wiring method and the type of switch differ. In the diagram below, we show wiring diagrams for both a single-phase and a three-phase motor. For a three-phase motor, many wires need to be switched at the same time.

With a single-phase motor, a SPDT (single-pole double-throw) switch can do the job. However, with a three-phase motor, a "lossless" electromagnetic switch that offers an interlock structure is required. This type of switch does not allow two contacts to be turned on at the same time. If any of the two windings are powered at the same time, it could create a power short circuit, and then the circuit breaker could stop the motor. |

🗒️Watch Out for Brake Frequency

Brake frequency is limited by the temperature rise of the motor, and temperature rise is mostly affected by the inrush current, which happens when you energize the windings of a motor to run in either CW or CCW direction. Inrush current is higher than the normal rated current, and current is proportional to temperature, so the more the motor is cycled ON/OFF, the higher the temperature rise. Since we don't want to overheat the motor, we need to limit the brake frequency.

To determine the maximum brake frequency, testing is recommended. For both single and three-phase induction motors, it's recommended to allow 2 or 4 seconds minimum per cycle (depending on motor size) before the next cycle. That comes out to be about 30x a minute for 6~40 W motors, and 15x a minute for 60~90 W motors. It's OK to exceed these reference values as long as you can maintain the temperature, but remember, a higher temperature will decrease long-term life.

Oriental Motor offers a full line of AC induction motors from 1 W (1/750 HP) to 400 W (1/2 HP). In addition to induction motors, reversible motors, electromagnetic brake motors, torque motors, and washdown motors are also available. Various types of gearheads can be added for high torque applications.

Product series groups vary by type(s) of motor and features. For example, the World K Series is our standard AC motor series that includes many types of motors from induction to electromagnetic brake types. The KIIS Series is the three-phase portion of the KII Series, which retains the high torque characteristics from the KII Series with improved efficiency and speed control performance.

Here's a breakdown of our lineup of three-phase AC motors.

|

|

On our website, we break these down into "constant speed" and "speed control" AC motors. While "Constant Speed" AC motors include both single-phase and three-phase types, "3-Phase AC Motors for VFDs" focuses on only three-phase motors that are designed for speed control with VFDs.

Please subscribe to this blog to receive new articles in your inbox.

|

FYI Are There Better Motors for Instantaneous Forward and Reverse Operations? Remember, an instantaneous forward/reverse operation is not only limited to three-phase motors only. Any motor can perform forward/reverse operation, the deciding factor is how "instantaneous" and how "accurate" you want the operation to be. There are always trade-offs. Different types of motors offer different overrun and brake frequency specifications. A single-phase reversible motor uses a friction brake to reduce its overrun drastically for instantaneous forward/reverse operations. While the overrun is reduced to 2 revolutions at the motor shaft, the heat generated from the friction brake limits the duty cycle to 30 minutes at a time. For high frequency braking applications, we recommend either an electromagnetic brake motor (50 cycles per minute) or a single-phase motor with a brake pack (60 cycles per minute). For applications requiring instantaneous stops but not a specific stop accuracy value, a brushless motor system with a dynamic braking system may suffice. Stepper motors or servo motors offer the best stop accuracy, starting torque, and stop accuracy for instantaneous forward/reverse operations, but it takes more to control these motors than an AC reversible motor. Here's some comparison data between all the motors that can perform forward/reverse operations. Remember these overrun values are at the motor. If you add a gearhead, divide the overrun by the gear ratio. These are reference values only.

|

With such a wide product breadth, a motor sizing consultation with our technical support engineers is recommended to narrow down your product options.

.jpg?width=600&height=343&name=Wiring%20comparison%20(translated).jpg)