For automated factories, motor failures mean lost production and lost revenue. Being able to identify the specific issue in advance and its location is critical to maintaining production efficiency. To be successful, extra sensors must be added to detect abnormalities. There may be an easier way.

| Challenge | Monitor Your Machine Like a Traffic Light System |

Using motor systems with status monitoring capabilities is one way to make lives easier for everyone involved. Being able to monitor various statuses of a system is the basis of predictive maintenance, which can identify potential issues before they become actual problems.

First, we need to decide what we want to monitor from the motor. Besides excessive load, heat is a motor's #1 public enemy. A motor's life is rated by its bearing grease life, and the bearing grease life is rated based on operating temperature. For this example, we will focus on most important variable that affects motor life - motor temperature.

Another decision we need to make is whether or not we need communication capabilities from the motor driver. Basically, we need to find out how to acquire that information. Is it acquired through data transmission through an industrial network, an analog output, or digital I/O?

| TIP: Benefits of Networking | |||

A good way to minimize time-consuming I/O wiring is to connect using an industrial communication network, such as EtherNet/IP or EtherCAT. The number of wires that need to be connected between the master / host controller and the motor driver are significantly reduced.

Since a driver is limited by the number of its physical I/O, more "remote" I/O can be accessed by setting up an industrial network with the motor driver. This means more variables can be monitored. Examples of other status outputs that can be monitored:

|

After you decide which variables you want to monitor, find the specific outputs that can output this data, then connect them to your PLC, PAC, HMI, or whatever you're using as a monitoring system. Once connected, the status information can be continuously communicated to the master via I/O or industrial network. The settings for the programmable output can be set up with a different threshold to fit various needs.

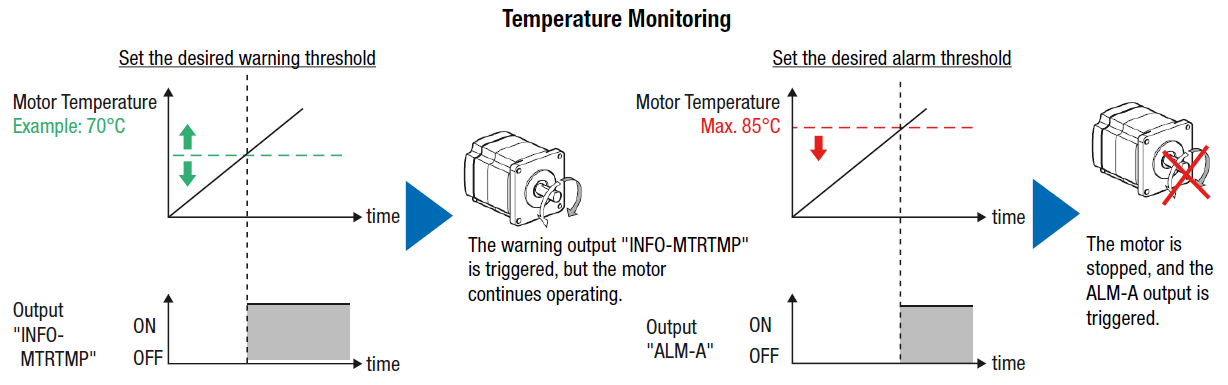

In the following image, we show how these "information" outputs work.

In this example, The INFO-MTRTMP output is set up to trigger ON if the motor's operating temperature exceeds 70° C. The ALM-A output is set up to trigger ON if the motor's operating temperature exceeds 85° C. The difference, besides the obvious temperature thresholds, is that when the ALM-A output triggers, the motor will also stop operating.

| TIP: What is the Difference Between a Standard Output and an Information Output? |

|

This is only specific to Oriental Motor's products. A standard output is a default, physical output that is assigned at the factory. An information output is a optional output that can only be accessed through an industrial network or with the MEXE02 software status monitor function. The INFO outputs are designed to provide warnings before the alarm generates and stops the motor. |

Now, how are we going to show this information to the operator?

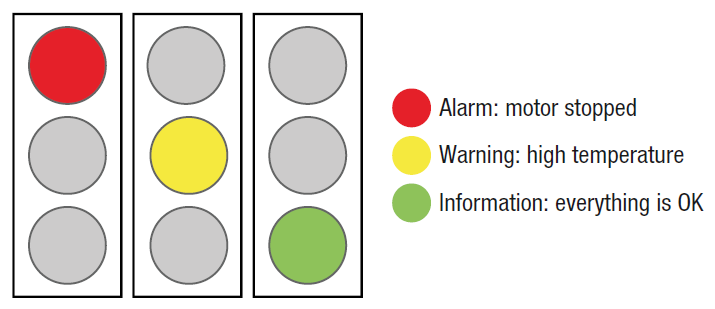

To show the concept, we will show the status with a traffic light system. It is the easiest concept to use in our application example.

- GREEN - everything is OK and the motor is operating normally.

- YELLOW - INFO-MTRTEMP output triggered ON indicating that temperature is above 70° C.

- RED - ALM-A output triggered ON indicating that temperature is above 85° C.

Of course, a traffic light system may not work well in a real life scenario. For any kind of communication, you want the user to understand quickly so action can be taken quickly. How the information is displayed is up to the operator or programmer.

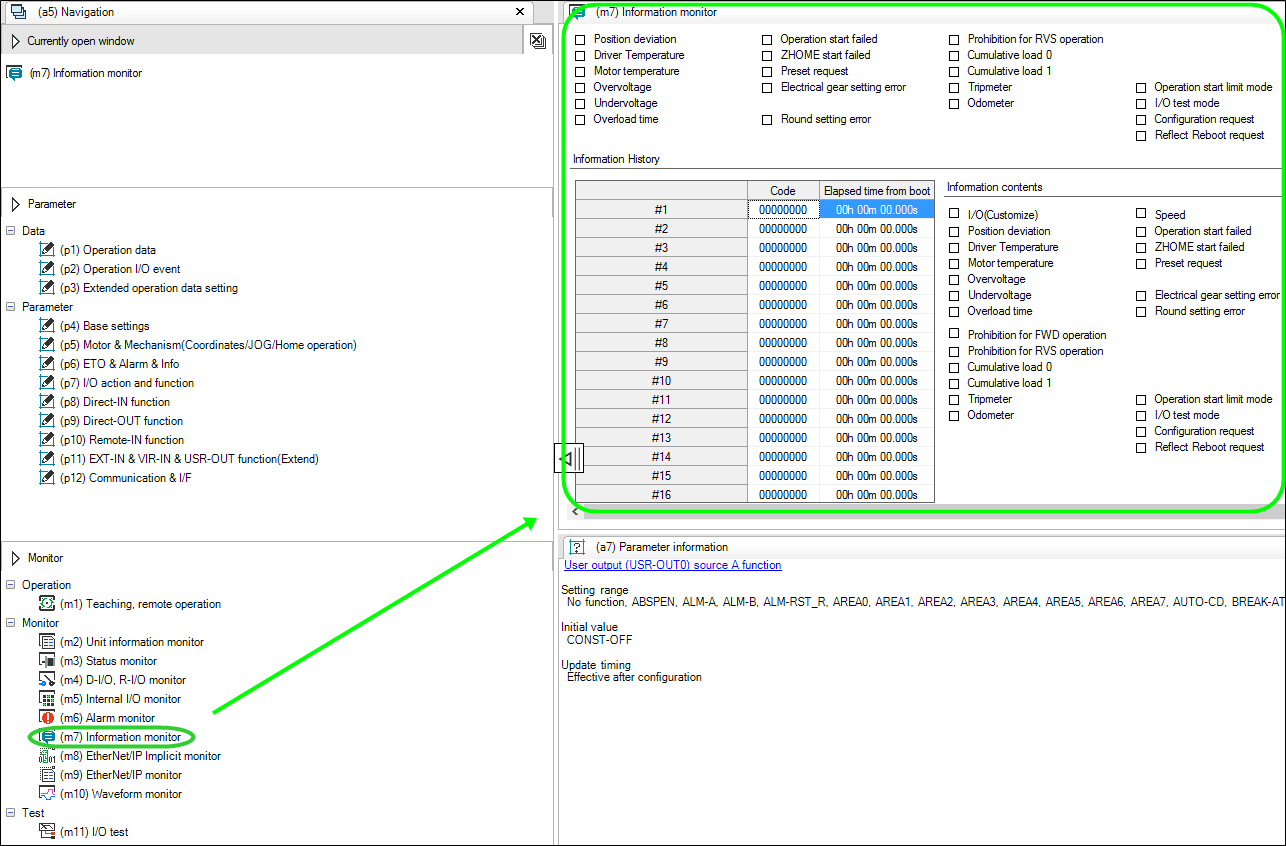

Here's another status monitor example. This time, we're using our dedicated MEXE02 software to monitor these information outputs. This function can be accessed with the "Information Monitor". Of course, this software was designed to monitor one motor at a time. An operator's interface at a factory will contain specific IDs to identify which motor axis is at fault.

FYI when communication is established between the software and the driver, some boxes should be colored and some boxes will stay blank. Make sure to click the check box to start monitoring.

Most importantly, to make all this happen in the best way, a driver with industrial communication capabilities may be necessary. These drivers offer communication ports and can provide a lot more data than a driver without communication. It really depends on what you want to monitor.

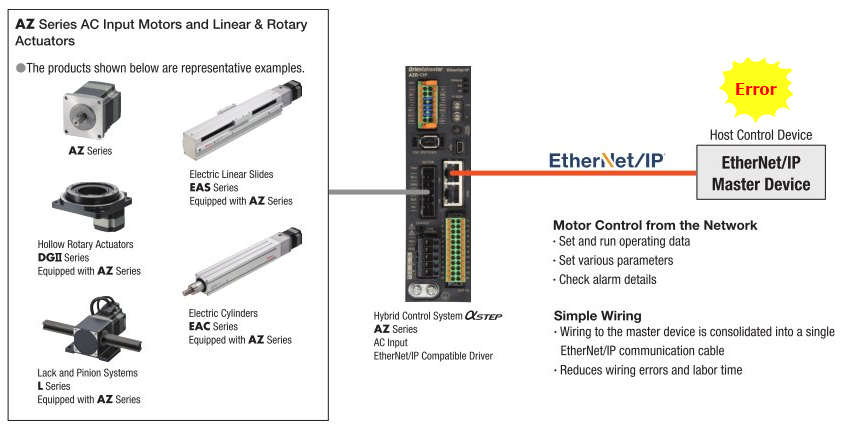

Oriental Motor offers dedicated EtherNet/IP or EtherCAT compatible drivers for AZ Series equipped  ,

,  , and

, and  .

.

| Solution | AZ Series Network Type Drivers |

| Single-Axis | Single-Axis | Multi-Axis |

|

|

|

|

|

|

|

|

|

Here's a video tutorial that shows how to use an AOI to monitor motor status on the Studio 5000 Logix Designer software from Rockwell Automation (for Allen Bradley PLC users).

Thanks for reading. Please subscribe to receive new posts, and feel free to comment if you have something to add to this post.