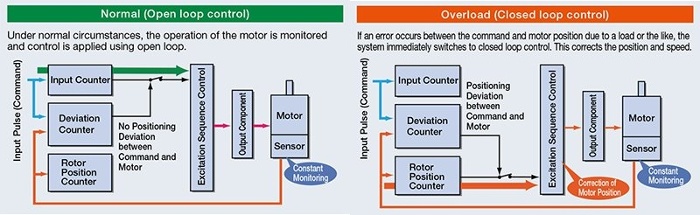

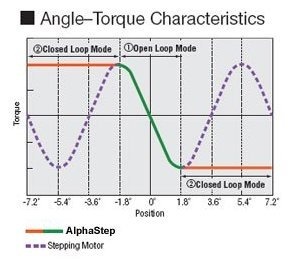

The word, "AlphaStep", describes Oriental Motor's patented Hybrid Control technology, which offers improved stepper motor performance by sensing the rotor position and automatically switching between open-loop and closed-loop operation when necessary. This post explains the unique technologies offered within the AlphaStep family of products and summarizes the numerous integrated options available. It also can serve as a website navigation guide (video added).

First introduced in 1998 as the AS Series, the  ushered in a new age where stepper motors can emulate servo performance at a lower cost. Over the years, we improved the AlphaStep Hybrid Control technology with two major advancements to close the gap between stepper motors and servo motors even further.

ushered in a new age where stepper motors can emulate servo performance at a lower cost. Over the years, we improved the AlphaStep Hybrid Control technology with two major advancements to close the gap between stepper motors and servo motors even further.

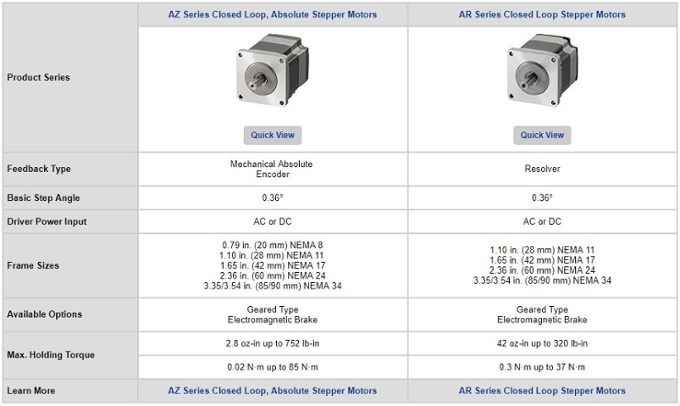

|

AlphaStep Hybrid Control Technology |

|

Normally open-loop. Closed-loop if necessary. When in closed-loop, torque is maximized. |

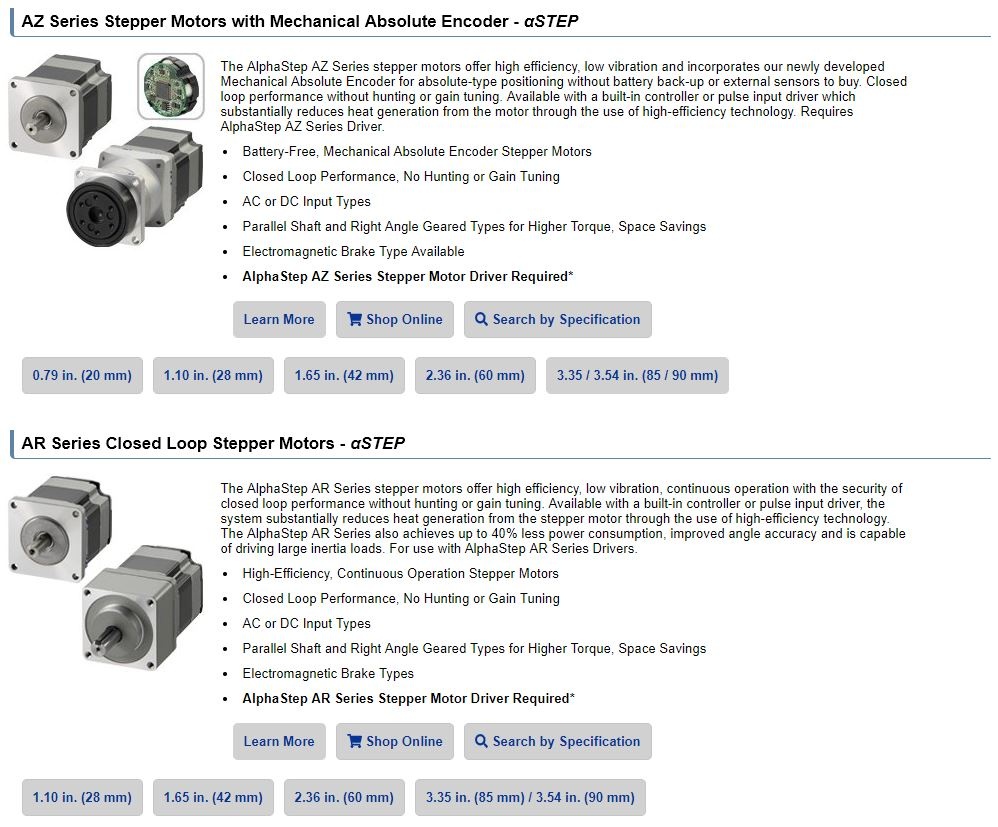

In 2007, the 1st major advancement of the AlphaStep technology was introduced with the AR Series. Combining its Hybrid Control technology with a  , the low loss characteristics allowed continuous duty cycles with stepper motors, which was revolutionary at the time and can increase throughput of a machine without overheating. However, similar to absolute encoders, its resolver feedback system required a battery for absolute position control.

, the low loss characteristics allowed continuous duty cycles with stepper motors, which was revolutionary at the time and can increase throughput of a machine without overheating. However, similar to absolute encoders, its resolver feedback system required a battery for absolute position control.

With the newest AZ Series introduction in recent years, we kept the existing two technologies from the AS Series and AR Series, and added battery-free absolute position control capabilities with the  . With all 3 technologies combined into one product, the AZ Series presents a viable alternative to servo motor systems. More recently, we've been working on offering AZ Series motors with all types of gearheads and actuators to expands its application range.

. With all 3 technologies combined into one product, the AZ Series presents a viable alternative to servo motor systems. More recently, we've been working on offering AZ Series motors with all types of gearheads and actuators to expands its application range.

With an easy-to-use  , advanced linked motion sequences can be programmed easily and stored within the dedicated drivers to lessen the burden on the host controller and decentralizing control. With its wide product breadth in both rotary and linear motion, the AlphaStep family can truly support complete standardization of all motion axes within a machine or even a production line.

, advanced linked motion sequences can be programmed easily and stored within the dedicated drivers to lessen the burden on the host controller and decentralizing control. With its wide product breadth in both rotary and linear motion, the AlphaStep family can truly support complete standardization of all motion axes within a machine or even a production line.

Here's a video demonstrating how an entire production line can be automated with the AlphaStep family of products.

Now that we understand what the AlphaStep family can do, let's dig deeper into the AZ Series and learn about all the options available.

- Good starting point

- Driver input voltages

- Available frame sizes

- A wide variety of gearhead options

- Numerous rotary and linear actuator options

- Dedicated drivers guarantee product specifications

|

Don't have time? Here's a video to show you how to navigate our website. |

| Or...read the detailed explanation below. |

|

Good Starting Point |

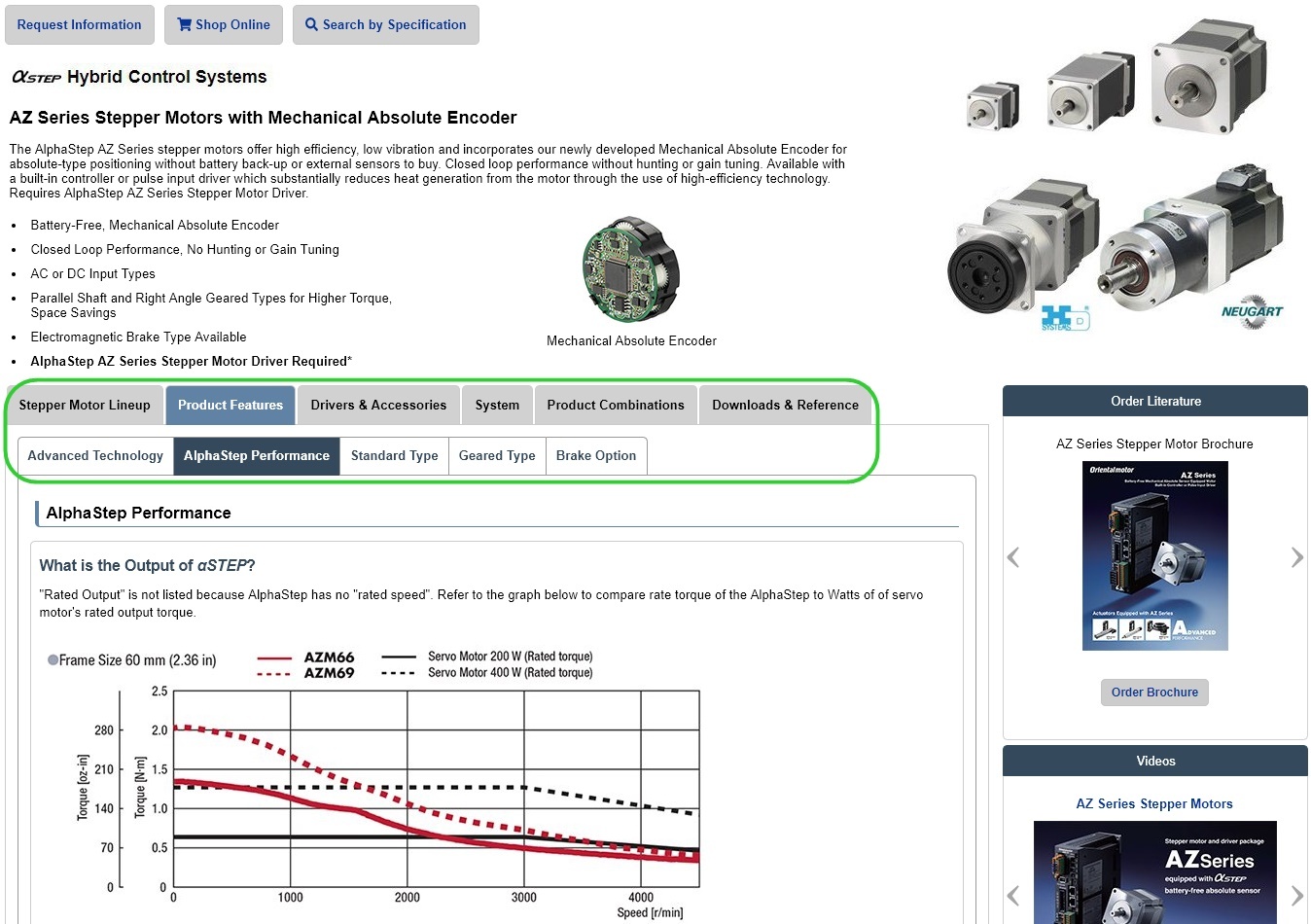

Here's a  that consolidates all the products that offer the AlphaStep Hybrid Control technology. There will be a brief introduction of the technology and different tabs to show specific information about motors and drivers.

that consolidates all the products that offer the AlphaStep Hybrid Control technology. There will be a brief introduction of the technology and different tabs to show specific information about motors and drivers.

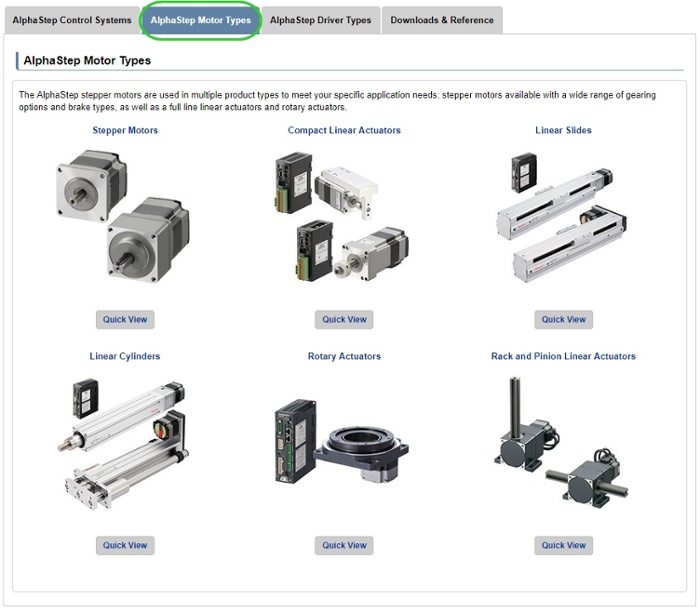

If you click on the 2nd tab labeled "AlphaStep Motor Types", you should see 6 categories: Stepper Motors, Compact Linear Actuators, Linear Slides, Linear Cylinders, Rotary Actuators, and Rack and Pinion Linear Actuators. When you click on any of these categories, then the different product series will be shown.

For example, click on "Stepper Motors", you will see the product series offered for that category.

|

TIP: Use Compare Products to compare products in the same category. |

Once you select a product series, you will be taken to an overview page. Click on different tabs to learn about its lineup, product features, driver options, system configuration, product combinations, available downloads, and much more.

OK now let's see what options we offer in the lineup.

|

Driver Input Voltage |

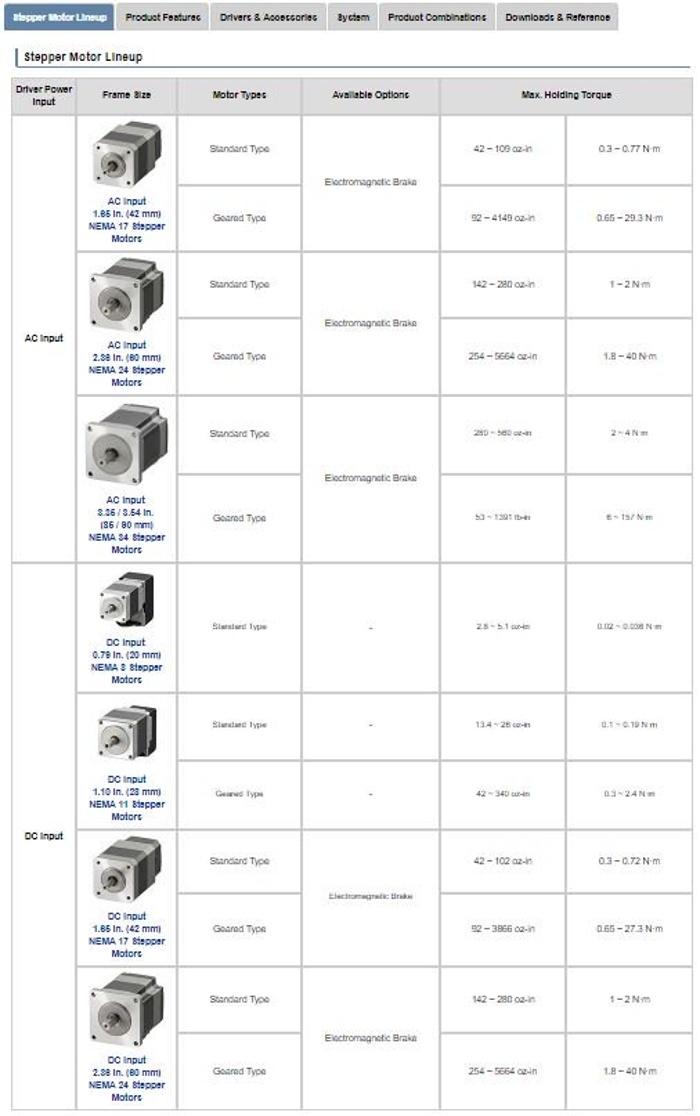

If you click the "Stepper Motor Lineup" tab on the same page, you will see a product table with "Driver Input Voltage" on the left side. This is where we list all the different configurations available within the product series. There are 2 options: "AC Input" and "DC Input".

| TIP: All stepper motors are DC input. "AC Input" motors are DC input motors with high voltage windings. "AC input" drivers are drivers that can output a higher bus voltage to these motors, which results in higher torque in the high speed region than the DC input types. |

|

Available Frame Sizes |

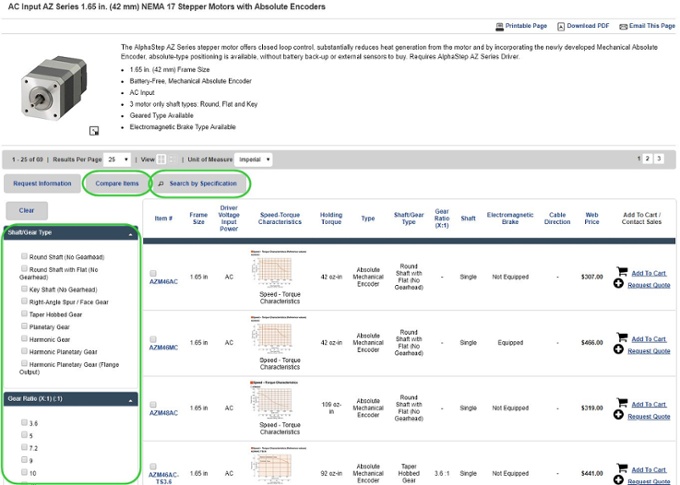

On the right side of "Driver Input Voltage", we show the available "Frame Size" options. The AZ Series offers 5 frame sizes: 20 mm (0.79" or NEMA 8), 28 mm (1.10" or NEMA 11), 42 mm (1.65" or NEMA 17), 60 mm (2.36" or NEMA 23), and 85/90 mm (3.35"/3.54" or NEMA 34). However, the frame size lineup varies due to "Driver Input Voltage". Smaller frame sizes such as the 20 mm and 28 mm frame sizes are offered only with "DC-Input" drivers.

Once you select a frame size, then you will see a list of available motors. For example, if you select "AC Input 2.36 in. (60 mm) NEMA 24 Stepper Motors", you should see 78 part numbers. This should give you an idea of its product breadth.

With a family of compatible, interchangeable products, the true power of the family is the ability to combine different products to fit exact requirements.

|

A Wide Variety of Gearhead Options |

Various types of gearheads are offered for the AZ Series motors. Each offers its own advantages and disadvantages, such as output torque and backlash. While the motors offers between 2.8 oz-in to 560 oz-in torque, the gearheads expand its range to 1,391 lb-in.

| Taper Hobbed (TS) | Planetary (PS) | Planetary (PLE) from Neugart |

| Up to 220 lb-in (25 N·m) | Up to 320 lb-in (37 N·m) | Up to 1,391 lb-in (157.16 N·m) |

| Backlash: 25 arc min (0.42°) | Backlash: 7 arc min (0.12°) | Backlash: 9 arc min |

|

|

|

| Harmonic Planetary (HPG) | Right Angle Face / Spur (FC) | Harmonic (HS) |

| Up to 210 lb-in (24 N·m) | Up to 92 lb-in (10.5 N·m) | Up to 460 lb-in (52 N·m) |

| Backlash: 3 arc min (0.05°) | Backlash: 15 arc min (0.25°) | No backlash |

|

|

|

|

TIP: Gear options are shown once you select a frame size. Use the "Advanced Search" or Search Filters on the left side of the results page to narrow down your results. You can also compare items. |

|

Numerous Rotary and Linear Actuator Options |

Besides gearheads, we also offer integrated rotary and linear actuator options with the AlphaStep AZ Series or AR Series technology. The page below shows all available actuator options. Click on the product type to learn more about its offerings.

- Compact linear actuators offer small footprint and high accuracy.

- Linear slides offer a slim design and a load carriage for XYZ motion.

- Linear cylinders are great for pushing with controlled force.

- Rotary actuators offer increased rigidity are great for index tables with high inertial load.

- Rack and pinion systems offer long stroke and high load capacity.

|

Dedicated Drivers Guarantee Product Specifications |

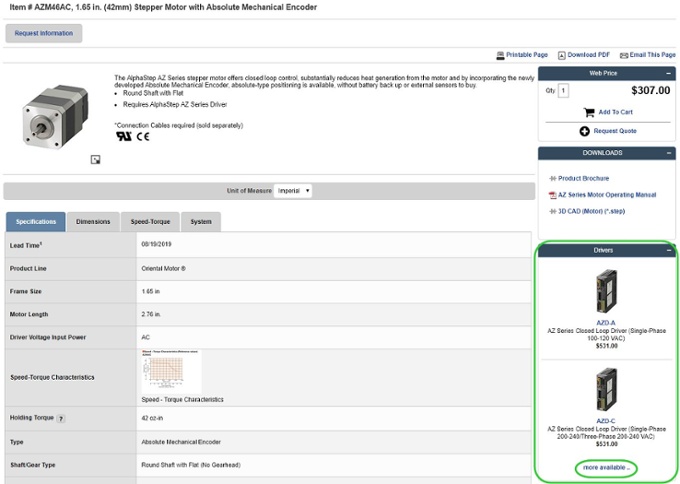

AlphaStep drivers are universal type drivers and differ only in input voltage and functions. The list of driver options are shown on a part number page, or when adding an item into the shopping cart. These dedicated drivers can identify the motors once connected, and motor parameters such as voltage and current are automatically adjusted. Dedicated drivers are tested products that guarantee specifications.

- Pulse Input - accepts pulse train from a host controller

- Pulse Input + RS485 - accepts pulse train + Modbus RTU commands*

- Stored Data + RS485 - accepts stored data with software input + Modbus RTU commands*

- EtherNet/IP - accepts EtherNet/IP commands

- Multi-axis EtherCAT (DC input only) - connect up to 4 motors + accepts EtherCAT commands

*For other industrial communication protocols, we also have network converters available.

For example, this is what is shown if you select the "AZM46AC" motor, which is an "AC Input AZ Series 1.65 in. (42 mm) NEMA 17 Stepper Motors with Absolute Encoder". You will see compatible driver options on the right along with accessories and cables. The nice thing about our website is that once you're on a part number page, it will only show you compatible options. These are also shown when you add an item into the cart.

|

TIP: Click on "more available" to see all driver options. |

There you have it. Now you've met the whole family. If you have any questions, our knowledgeable technical support engineers can help you find the most ideal product for your application and guide you through the motor sizing and selection process.

Learn more about the AlphaStep family by watching  on our website (see Stepper Motors - AlphaStep), or follow #AlphaStep on social media (

on our website (see Stepper Motors - AlphaStep), or follow #AlphaStep on social media ( ,

,  and

and  ).

).

|

Schedule a technical seminar to learn more about the AlphaStep family.