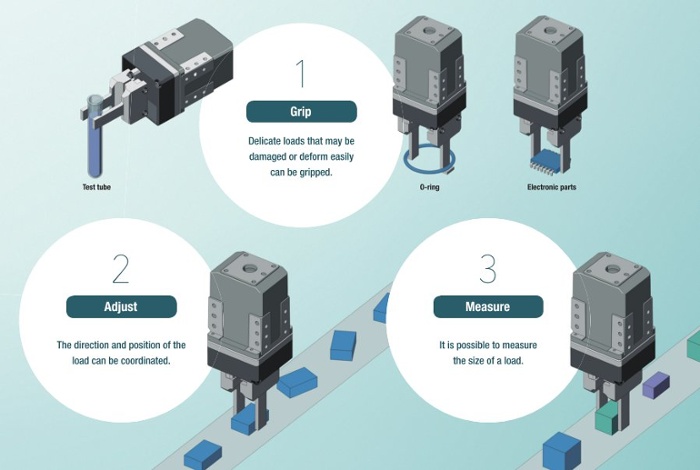

A gripper is typically an end effector that is installed at the end of a robotic arm or on a cartesian robot and can be used to grip parts in order to transfer them from one location to another. However, there's more to it than just closing the jaws to pinch a part.

In this post, we will explain how to properly grip a load while preventing damage.

| CHALLENGE | Grip a delicate part without damaging it |

|

A test tube holding test samples for a virus might be a type of load that should be gripped delicately. Along with positioning accuracy, the gripper should be able to automatically adjust its grip force and speed to avoid both excessive force and impact on the test tube. Even though we're using test tubes as the example here, the same concept can be applied to many types of loads. |

| SOLUTION | EH Series gripper system with stored push motion and speed data settings |

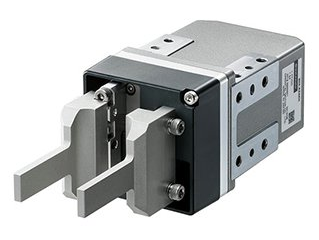

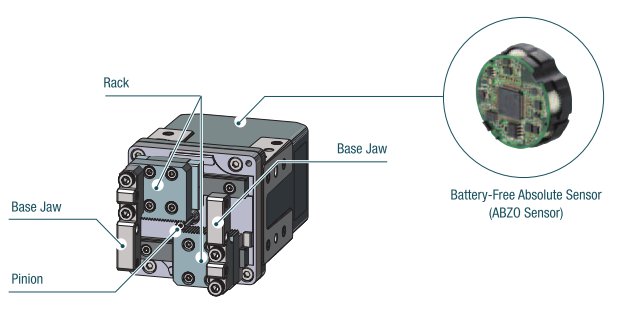

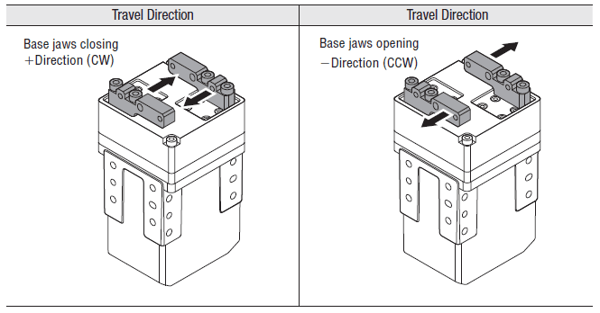

The EH Series gripper uses a design incorporating a dual rack and pinion system with 2 base jaws. As the motor rotates the pinion, the 2 base jaws can either extend or retract at the same time with a repetitive positioning accuracy of +/-0.02 mm. Standard resolution is 0.02 mm per step but can be changed by software. Different gripper arms, or pincers, can be mounted to the base jaws to suit a variety of load types.

There are a variety of dedicated DC input driver options available to satisfy every need.

|

A Pulse Input type driver is recommended for users who want to use traditional step/direction pulse command to control the motor and access I/O through wiring.

A Pulse Input + Stored Data (RS-485) type driver is recommended for users who want to use step/direction pulse command to control the motor, but also want to monitor driver status remotely through an RS-485 network. For drivers with RS-485 capability, 2 communication ports are offered, and Modbus RTU communication protocol is standard. Other protocols are available with network converters.

A Stored Data (RS-485) type driver does not offer pulse/direction inputs, so commands would be sent entirely from a master host controller in an industrial network (as well as status monitoring requests). This type of driver can eliminate a lot of physical wiring for the user and simplify the setup.

Allen Bradley PLC users and Beckhoff PLC users can use either the EtherNet/IP driver or EtherCAT driver to easily connect their host controller. AOIs are available.

These gripper systems offer several functions that can help improve gripping operations. The battery-free absolute sensor (ABZO sensor) can help minimize footprint by eliminating external home and limit sensors as well as batteries for absolute encoders. Furthermore, the AlphaStep hybrid control technology ensures reliable operation and prevents missed steps.

For the purpose of this post, we will use a Stored Data (RS-485) driver as an example.

The stored data (RS-485) driver is capable of storing 256 different motion profiles (more possible by network command). This includes position distance, push motion settings as well as speed data. Once these data sets are programmed with the universal MEXE02 support software, they are stored within the driver. BCD (binary coded decimal) inputs can be used either physically or remotely via an industrial network to execute the stored motion profiles.

|

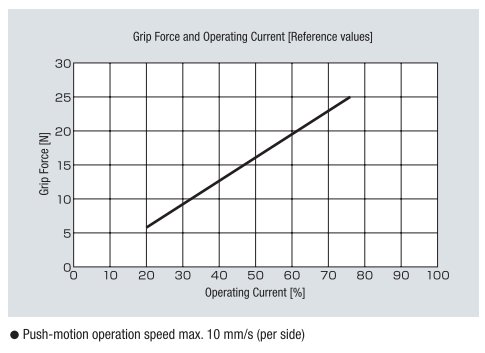

What Is Push Motion? A push motion function is a way to limit the torque of a stepper motor by monitoring and limiting its current. A motor's input current is proportional to its torque output. By accurately limiting a gripper motor's current in 1% increments, the grip force can also be controlled precisely.

|

Now that we understand the functions of each part in a gripper system, we can move onto how to use the EH Series gripper system to properly grip a load without damaging it.

| Key Point | Use push motion with multiple speed settings to minimize impact force and impact |

With the linked motion sequence function to link multiple motion profiles as one, a continuous motion profile with different push motion force settings and speeds can be created.

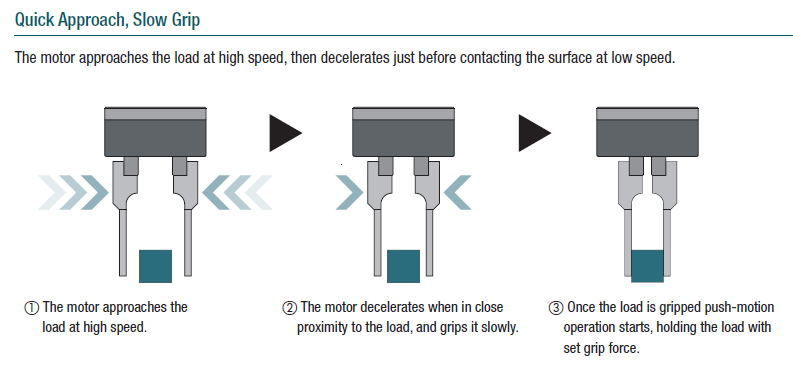

For a type of delicate load like test tubes, we would want a gripper to approach it at a high speed, then slow down when in close proximity of the load, and grip it slowly. When a set grip force has been reached, the gripper stops and holds that grip force constant until the part is dropped off.

First, let's take a look at what a push motion operation looks like with a soft load like a sponge.

Second, let's see how adding a variable speed operation would help.

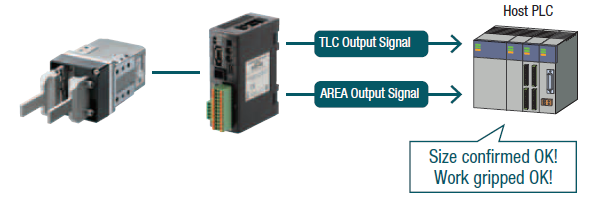

Additionally, the built-in mechanical absolute encoder in the EH Series grippers can be used to detect the load, or confirm dimensions of the load. The dedicated stored data driver offers useful outputs, such as TLC, MOVE and AREA, that can be accessed physically by wire or remotely by network.

- TLC Output: turns on when a set grip force has been reached

- MOVE Output: turns on when the motor is moving

- AREA Output: turns on when the motor is within a set position range

Let's look at how this operation looks like.

If wiring is not your preference, the same operation can be done by network command and a handy status monitoring function.

Conclusion

By combining push motion, speed settings, mechanical absolute encoder output, and TLC/MOVE/AREA outputs from the driver, a reliable gripping operation can be performed quickly and efficiently with delicate parts.

Simplify your setup and control by using products from the same AlphaStep family. For example, all the AlphaStep products with the AZ Series mechanical encoder technology use the same dedicated drivers, so each axis can be added easily and quickly. Stored motion data and parameters can also be transferred from one axis to another. To help shorten the learning curve,  are available.

are available.

Thanks for making it this far! Remember to subscribe if you want to be notified of new posts.