There are many stepper motor manufacturers in the market place, but there are even more stepper motor driver manufacturers. The crowded market place provides many standard product options for customers to build their motion control system just the way they like it.

However, if the best possible performance is desired, it would be difficult to beat a tested combination of a specific motor and driver from the same manufacturer. By combining R&D knowledge from both motors and drivers, unique product features can be developed to improve performance further.

In this post, we discuss 3 advanced features of the CVD stepper motor drivers that were designed to improve the performance of the PKP Series high torque stepper motors: stable torque output even when microstepping, high efficiency components for high current output, and why buying both motors and drivers from the same manufacturer is better.

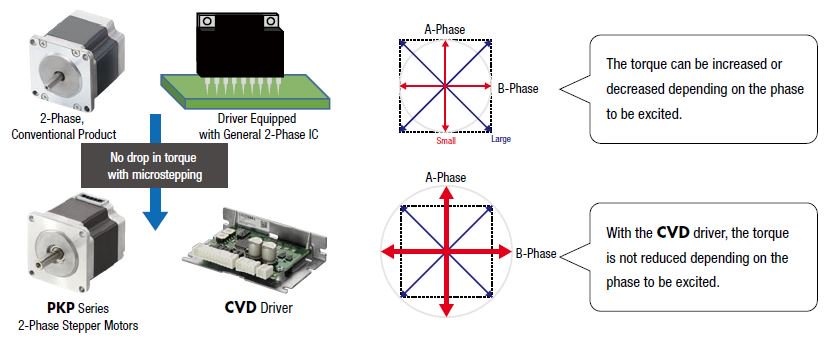

Consistent Torque Output Even When Microstepping

Microstepping is a driver function that electrically subdivides the full step angle of a stepper motor in order to increase resolution or decrease vibration and noise. Traditionally, inconsistent torque output or position accuracy are problems resulting from microstepping. Due to individual motor phase current detectors as well as sine wave current drive technology, the CVD drivers can regulate torque more precisely even when microstepping.

High Efficiency, Low Heat Design

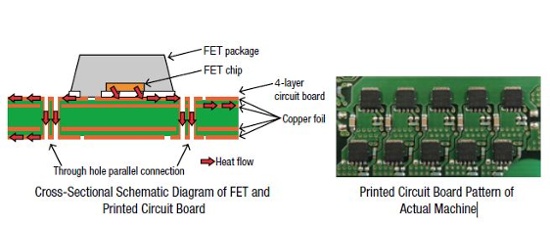

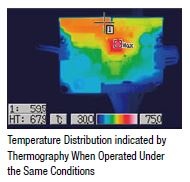

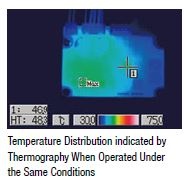

To increase the motor torque, the current from the driver to the motor must be increased. However, increasing the current also increases the operating temperature for the driver, which can limit duty cycle or decrease life of the driver. The CVD drivers utilized a low heat, high efficiency design, which makes it possible to apply a higher current to the motors.

- Adoption of more efficient FETs for better heat transfer from the components to the PCB. On resistance of new FETs are 1/20th of conventional FETs.

- Improved heat transfer circuit board design helps minimize footprint. No heat sink is required.

|

|

|

|

|

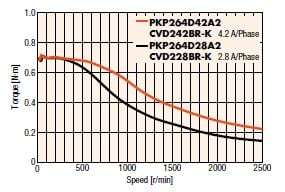

With a stepper motor and driver that's rated for higher current, high speed torque can be increased without changing the motor size. Here we show 2 PKP Series stepper motors of the same frame size and stack length. By changing from a 2.8 A/phase winding to a 4.2 A/phase winding, we can increase the motor's torque output as seen in the speed torque curve.

|

|

|

|

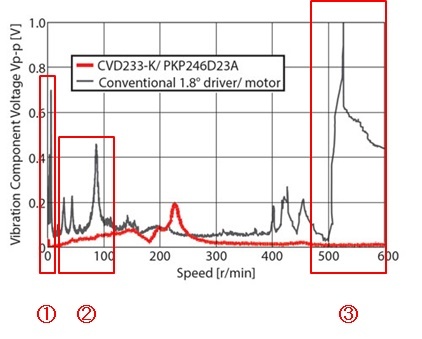

Unmatched Performance and Precision

The CVD driver offers superior low vibration and noise characteristics by using a new, fully digital, full-time microstepping control circuit. Current waveform and torque consistency are improved. The Smooth Drive function provides quiet and smooth stepper motor performance that internally microsteps the basic step angle to a maximum resolution of 2048.

As a result, the CVD drivers can provide unmatched stepper motor performance with significantly reduced vibration and noise.

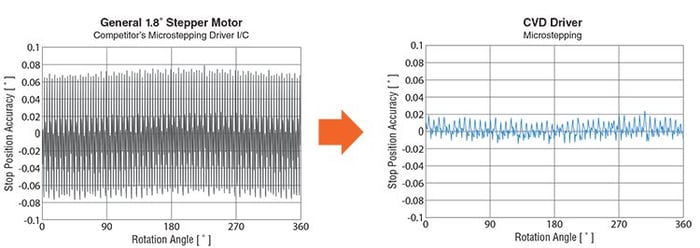

In general, the stop accuracy of stepper motors is worse when microstepping since microstepping requires highly precise current control from the driver. With better current control from the CVD driver, the stepper motor can actually perform better than its standard specification of ±3 arc minutes (±0.05º).

the following video to learn how the CVD drivers can improve the performance of stepper motors.

the following video to learn how the CVD drivers can improve the performance of stepper motors.

If you wish to learn more about the features of our CVD driver in depth, please read our  .

.

Watch related  or size your next stepper motor with our

or size your next stepper motor with our  .

.

There are multiple product lines of CVD drivers.

If you need help, please discuss your requirements with our team.

Building your own? Ask about the S-Type Board Mounting Type driver