Historically, stepper motors are not rated by watts like AC motors or servo motors. So...how would you compare a stepper motor to a servo motor or a brushless motor?

.gif?width=365&height=274&name=Teruyo%20(stepper%20wattage).gif)

The reason why stepper motors are not rated in watts is because there is no concept of rated rotation speed (RPM) for stepper motors.

Why do we need the rated speed?

AC motors and servo motors are rated for maximum power, in watts, at their rated speeds. Since stepper motors don't have a standard rated speed value, Oriental Motor does not show a wattage specification for stepper motors. If necessary, the wattage value can be calculated.

Formula for output watts

| Output [W] | = | 2 × π × T × N | ≒ | 0.1047 × T × N |

60 |

= 0.1047 x T x N

0.1047: Constant

T [N m]: Torque

N [r/min]: Rotation speed

How do you choose the rated speed?

Even though there is no rated speed for stepper motors, it's theoretically possible to derive the output wattage from the formula above based on the operating speed. However, the output watts value will change according to the rated speed you choose.

Here's a general reference for other types of motors:

- AC small standard motor: 1,500 r/min at 60Hz (depends on model)

- Brushless motor: 3,000 r/min (depends on model)

- AC servo motor: 3,000 r/min

Let's look at some examples.

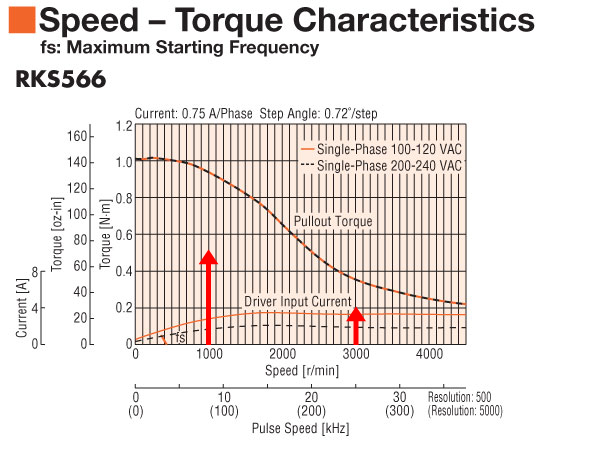

●PKE566AC motor + RKSD507-AD driver (RKS566AA system) speed - torque characteristics

-

- 1. 0.1047 x 0.5 x 1000 = 52.3 W when calculated with a rotation speed of 1000 r/min and a torque of 0.5 Nm.*

- 2. 0.1047 x 0.2 x 3000 = 62.8 W when calculated with a rotation speed of 3000 r/min and a torque of 0.2 Nm.*

- *The red arrows only go up half way to the speed-torque curve because the safety factor is typically 2:1 by default for stepper motors, so the selection was made so that the pullout torque is not exceeded when the required torque is doubled.

Let's look at another example. How about comparing servo motors to brushless motors?

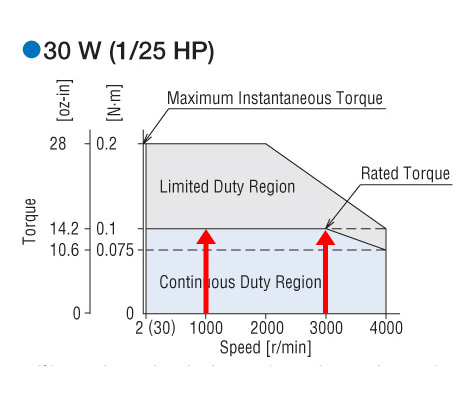

●BXM230-A2 motor + BXSD30-A2 driver (BXS230A-A system) speed - torque characteristics

- 1. When calculated at a rotation speed of 1000 r/min: 0.1047 x 0.1 x 1000 ≒ 10W.

- 2. When calculated at a rotation speed of 3000 r/min: 0.1047 x 0.1 x 3000 ≒ 30W.

| TIP | When comparing stepper motors to either servo motors or brushless motors, keep in mind that servo motors or brushless motors offer an instantaneous max torque for a limited time. Stepper motors typically do not offer this. |

Don't feel like calculating?

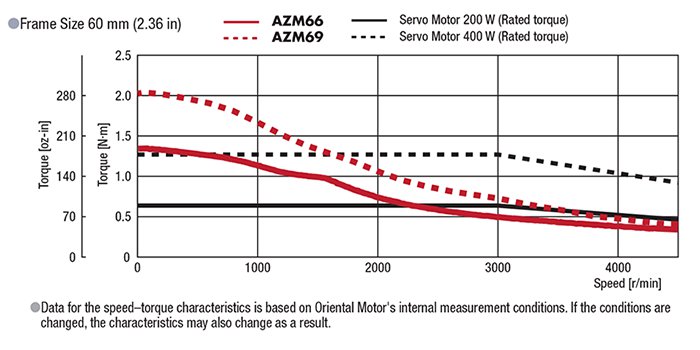

Here's a quick reference chart comparing our AlphaStep AZ Series closed-loop stepper motors with servo motors with equivalent output.

Example: AZ series stepper motors

| AZ series (standard type) | Servo motor with equivalent rated torque (reference) |

||

|---|---|---|---|

| Frame size | Part number | ||

| 42mm | AZM46 | Equivalent to rated torque of 50 to 100W | |

| AZM48 | |||

| 60mm | AZM66 | Equivalent to rated torque of 100 to 200W | |

| AZM69 | Equivalent to rated torque of 200 to 400W | ||

| 85mm | AZM98 | Equivalent to rated torque of 400 to 750W | |

| AZM911 | |||

If you're wondering, here's a comparison of speed-torque curves between a closed-loop stepper motor and a servo motor of equivalent output.

For comparisons of other sizes, please refer to https://www.orientalmotor.co.jp/products/stepping/overview_5/. Sorry, only Japanese is available at this time. I will try to update this post as they become available. In the mean time, please use Google Translate to translate the page.

Also, be aware of the fundamental and performance differences between stepper motors and servo motors. For example, servo motors work best for rigid mechanical setups at high speeds (ie: ball screw), and stepper motors work best for more compliant setups at low to medium speeds (ie: belt and pulley). To learn more, please read this blog post, The Choice Between Servo Motors and Stepper Motors.

Pick the right motor the first time! Contact our technical support engineers for a product sizing consultation.