Downtime is a no no for semiconductor fabs. Even a brief interruption can result in significant financial losses and disruptions in production. In this article, we explain how a linear actuator's built-in precision and reliability can simplify and even improve the design of wafer processing machinery, such as a silicon wafer pin lift.

What's covered:

- Why do wafers break easily?

- How can precision and reliability help with wafer handling?

- Why DR/DRS2 Series?

- Application Example: Silicon Wafer Pin Lifter with Compact Linear Cylinder

- Conclusion/Recommended Products

|

Why do wafers break easily? A wafer is a thin slice of semiconductor material, such as silicon, used for manufacturing integrated circuits (ICs). These wafers are circular in shape and are brittle like mirrors. According to Wafer World, they can break easily due to the pesence of even the smallest structural defect or excess stress force during production, handling, or transport. During production, ultra-pure silicon must be melted, then a singlel crystal must be pulled from the pool of molten silicon. |

|

How can precision and reliability help with wafer handling?

Precise and reliable motion control is crucial for wafer handling for several reasons:

- Wafer cleanliness: even the smallest particles or contaminants can cause defects or malfunctions in the final product. Precise handling minimizes the risk of introducing contaminants or causing scratches or other damage to the wafers.

- Alignment & positioning accuracy: lithography, etching, and deposition require extremely precise and consistent alignment and positioning of the wafer. Even slight misalignments can result in defective or non-functional products.

- Throughput and productivity: precise and reliable movements during wafer handling can significantly improve throughput and productivity by reducing cycle times and minimizing downtime.

- Complexity of wafers: accurate wafer handling is essential to ensure the successful fabrication of these intricate structures and maintain high levels of performance and reliability.

- Save money in the long run: sudden acceleration or too much thrust force may cause wafer cracks or position deviations. Precise control of motion profiles, including acceleration and deceleration, can reduce costs in the long run.

According to universitywafer.com, the cost of manufacturing a 12" wafer can be as much as $5,000.

With growing semiconductor demand due to AI, IoT (IIoT), and robotics, the use of precise and reliable motion control can scale production while minimizing costly damages and delays.

Application Example Silicon Wafer Pin Lifter with Compact Linear Cylinder

|

Wafer pin lifter systems built with DR/DRS2 Series compact linear actuators prioritize precision with an optional ground ball screw and built-in AlphaStep hybrid step-servo control for closed-loop reliability. Combined with battery-free mechanical absolute encoder technology, these compact linear actuators provide fail-safe operation with a fast "resume" function essential for minimizing downtime for high-volume wafer processing. |

|

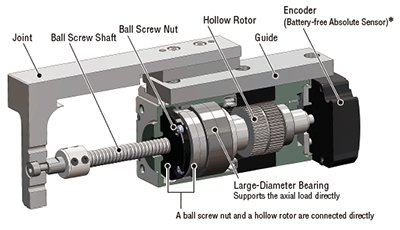

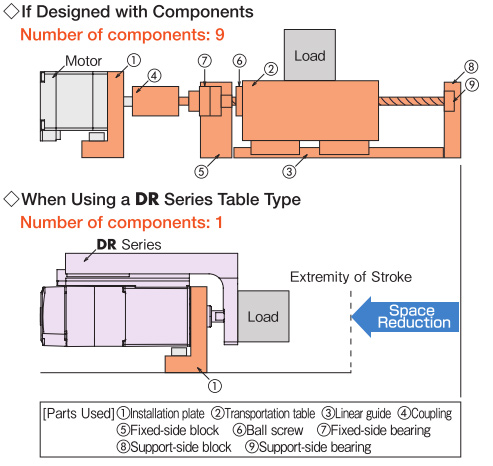

- Compact design with integrated ball screw mechanism

For multi-layer semiconductor processes where space is important, a hollow rotor design can minimize its footprint. A ball screw nut and a hollow rotor are connected directly, so no external connecting components are necessary.

|

|

- Precise movement with ground ball screw or rolled ball screw

This actuator can move in 0.001 mm increments. A rolled ball screw provides a repetitive positioning accuracy of ±0.01 mm while a ground ball screw provides a repetitive positioning accuracy of ±0.003 mm.

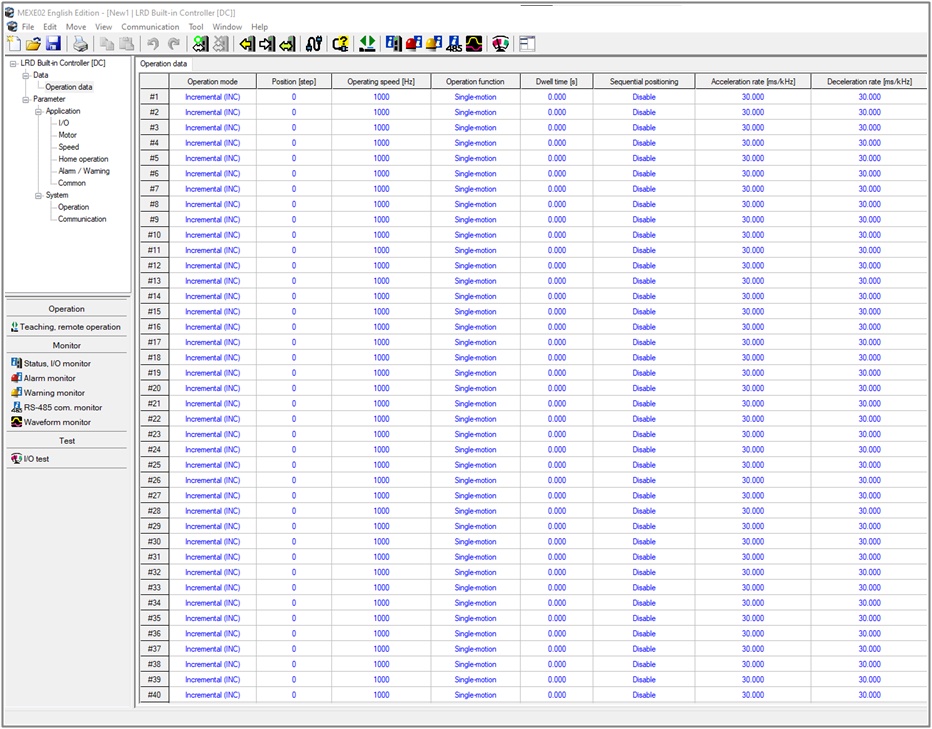

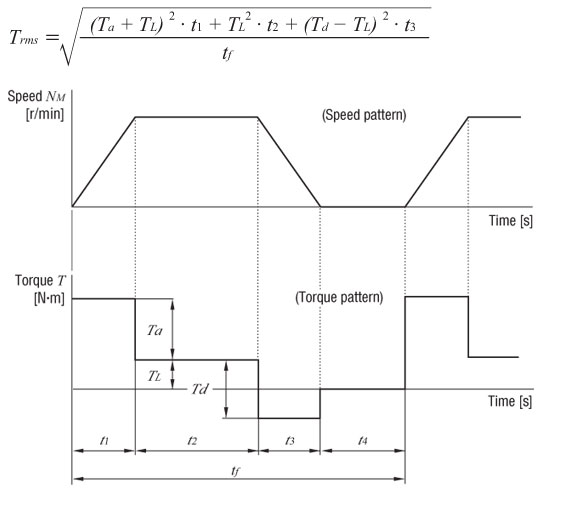

- "Smooth Drive" motion achieved through easy setting of acceleration, deceleration, and microstepping

A MEXE02 universal driver support software provides easy and quick programming of motion profiles and system parameters like acceleration/deceleration and Smooth Drive setting for better performance than pneumatic actuators.

|

|

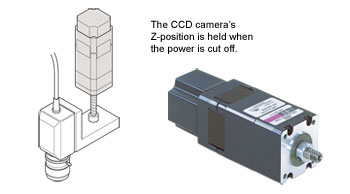

- An optional electromagnetic brake is available to avoid wafer from falling during power shut off

The power-off-activated electromagnetic brake engages when the power fails in order to prevent costly damages. In the example below, we show a DR Series compact cylinder with electromagnetic brake positioning a microscope vertically.

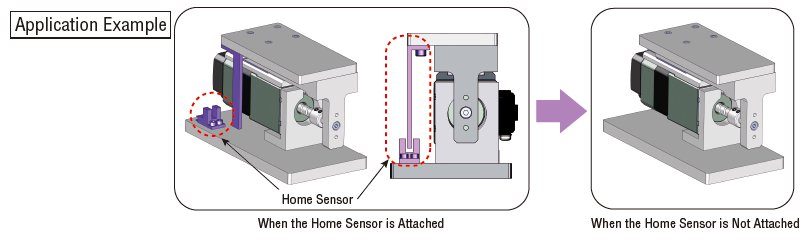

- Eliminate external sensors with battery-free absolute encoder technology

The built-in battery-free multi-turn absolute encoder can help minimize footprint and lower costs by eliminating the external home sensor, sensor flag, limit sensors, and cabling from each axis.

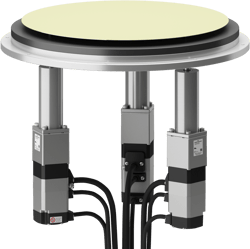

- Multi-axis driver moves 3 pins in a synchronous motion

For heavier loads, a multi-axis driver can move 3 linear actuators in synchronization. Without a multi-axis driver, the 3 axes may not start or stop at the same time.

| When multi-axis is used | Possible when multi-axis driver is not used |

|

|

Conclusion

The DR/DRS2 Series can be useful for silicon wafer pin lifting and lowering applications that require precise and smooth motion in a compact design. For applications requiring multi-axis synchronized motion, using a multi-axis driver can ensure that all axes start and stop at the same time.

Related article: Simplify Wafer Handling Machine Design with Modular Products from the Same Family

Our team of technical support engineers is standing by to answer your questions. Contact us and let us help!