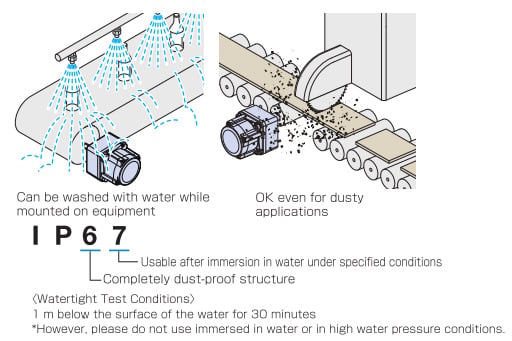

Electric motors drive our world, but they can be susceptible to environmental hazards like dust or water. This article explores IP ratings and codes, what they are, how they're tested, and why they're critical for motor durability and reliable performance.

Read More

Topics:

Conveyor,

AC Motors,

Speed Control,

VIDEOS,

BLDC Motors,

Washdown,

Application Examples,

Motion Control 101,

Motion Control Basics

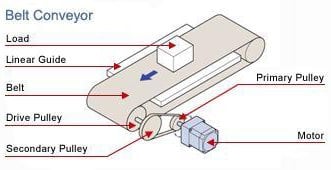

In today's fast-paced industrial landscape, the role of conveyors has become more crucial than ever. These systems efficiently move materials, products, and goods for numerous industries, from labeling and packaging to warehousing and distribution. While many types of motors can be used in conveyors, this article highlights a few reasons why brushless motors should be a primary choice for conveyor applications.

Read More

Topics:

Conveyor,

Speed Control,

VIDEOS,

BLDC Motors,

Application Examples

Many motor manufacturers offer a motor sizing tool to help with product selection, but if you don't know how to use it, you may still end up paying for it in the long run.

Read More

Topics:

Conveyor,

Speed Control,

Motor Sizing,

BLDC Motors

Which type of electric motor do you size for your conveyor, XYZ table, or robot? Before you select one, you must understand the characteristics of each type of motor in the market.

Read More

Topics:

Conveyor,

AC Motors,

Stepper Motors,

Speed Control,

Motor Sizing,

BLDC Motors,

Washdown,

Servo Motors,

Motion Control Basics

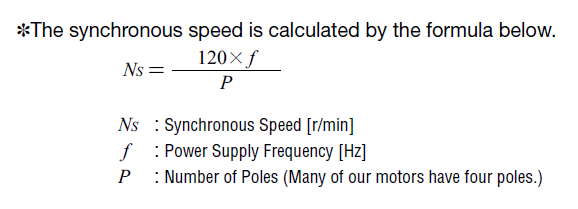

When a voltage is applied to an AC induction motor, it runs at a certain speed. Variable speed requirements for AC induction motors are typically fulfilled by a 3-phase motor and an inverter or VFD. This blog post also introduces another option.

Read More

Topics:

Conveyor,

AC Motors,

Speed Control,

Motion Control Basics

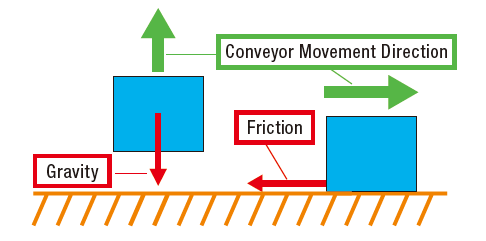

Proper sizing of a motor requires that 3 criteria must be met: torque, load inertia, and speed. For the first part of this Motor Sizing Basics series, I will be explaining what load torque is, how to calculate it for specific application examples, and how it fits into the torque requirement for the application.

Read More

Topics:

Conveyor,

AC Motors,

Stepper Motors,

Alphastep Hybrid Control,

Linear & Rotary Actuators,

Speed Control,

Motor Sizing,

BLDC Motors,

Servo Motors,

Rotary/Index Tables,

Motion Control Basics

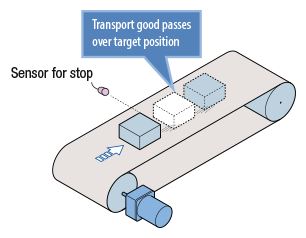

Are you using motors for a start/stop conveyor or similar application? While AC motors are a common choice for conveyors, there is a unique speed control motor solution available that could improve stop accuracy as well as reduce footprint and cost of machine designs.

Read More

Topics:

Conveyor,

AC Motors,

Stepper Motors,

Speed Control,

VIDEOS,

Application Examples

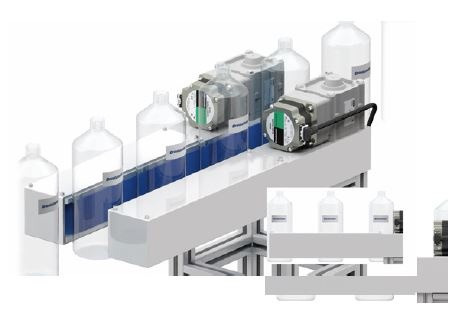

There are a variety of ways to synchronize the speed of multiple motors. In this blog post, we will explain another advantage of using brushless motors systems, which is its ability to set speeds accurately and be able to synchronize speeds on multiple axes easily . Brushless motors utilize built-in hall-effect sensors to regulate speed. Even if the load, input voltage, or temperature fluctuates, the speed regulation will always be under +/-0.2% or better.

Read More

Topics:

Conveyor,

AC Motors,

Speed Control,

VIDEOS,

BLDC Motors,

Washdown,

Application Examples

With the growing popularity of efficient brushless motors, replacing AC motors with these motors brings several advantages. In this blog post, we will uncover one of the advantages that can benefit lighter and compact equipment designs. If we just look at the motors, brushless motors are much more power efficient than AC induction motors. This means a smaller brushless motor can do the work of a bigger AC motor. With recent trends in efficiency, brushless motors should be considered during the motor selection process for new designs.

Read More

Topics:

Conveyor,

AC Motors,

Speed Control,

VIDEOS,

BLDC Motors,

Washdown,

Application Examples

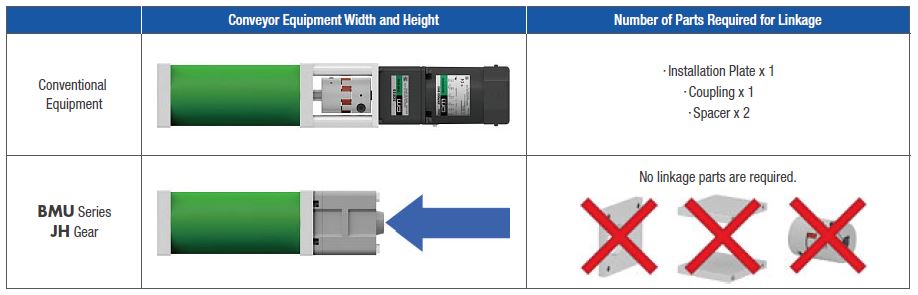

Parallel shaft gear motors are the standard configuration in the industry. However, right angle gear motors are gaining popularity for its ability to minimize the footprint of a machine, such as a conveyor. Another factor that should be considered is the type of gears used in the gearhead. While worm gear technology is popular, its gear efficiency can vary from 50~90% depending on gear ratio. On the other hand, hypoid gear technology keeps its efficiency at 80~95% regardless of gear ratio. Higher gear efficiency allows more torque to be transferred from the motor to the load shaft, and sometimes allows even smaller motors to be used.

Read More

Topics:

Conveyor,

AC Motors,

Speed Control,

VIDEOS,

BLDC Motors,

Gearheads,

Application Examples