Modern automation increasingly demands higher reliability, faster time-to-build, and easier scalability in a smaller package. If you’ve ever wished you had an easy button for motion control, Oriental Motor’s αSTEP Hybrid Step-Servo AZ Series product family lets you build your own compact, modular motion control solution by choosing off-the-shelf products.

Welcome to Oriental Motor's "Engineering Notes" Blog:

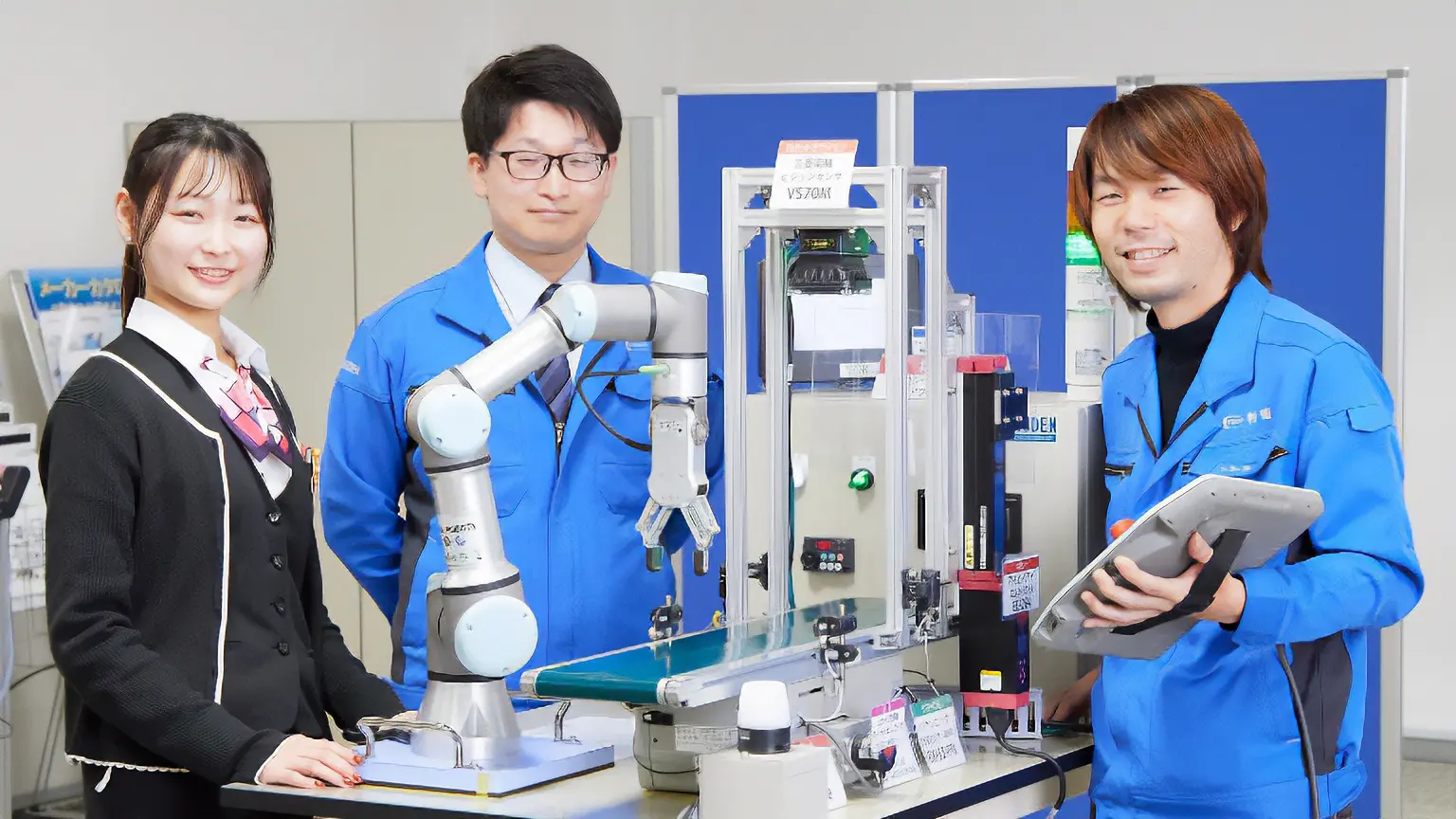

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

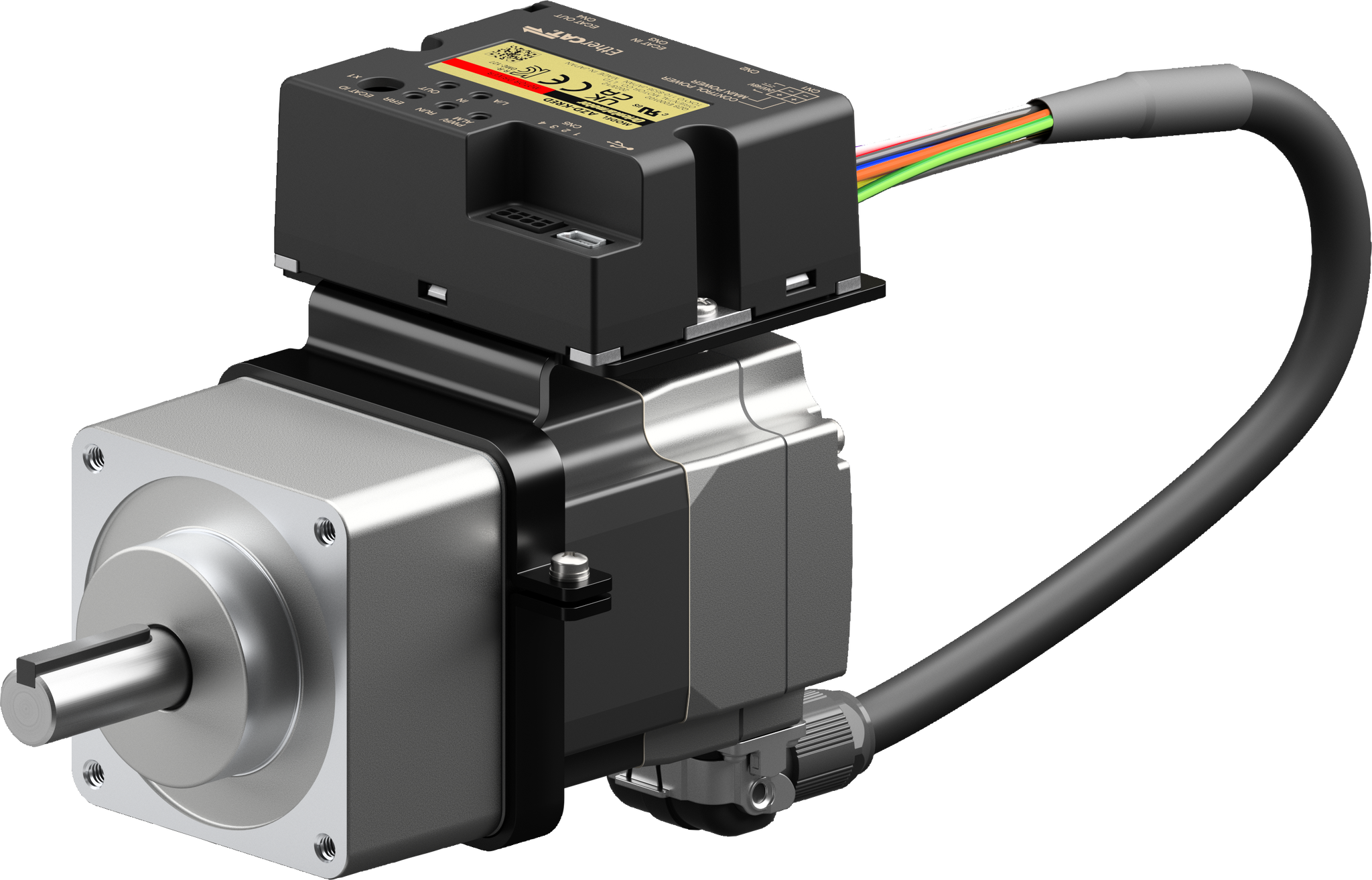

All-in-One Hybrid Step-Servo Solution for Compact Precision Automation

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, New Product Introductions

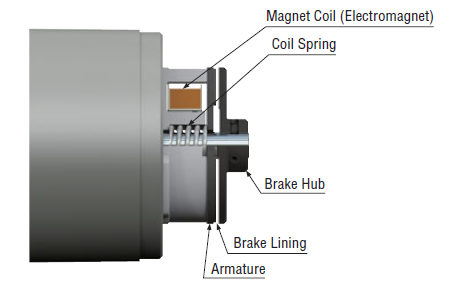

Why Electromagnetic Brake Type Motors are Necessary for the Medical Industry

Topics: AC Motors, Stepper Motors, Robotics, Linear Actuators, VIDEOS, BLDC Motors, Vertical Lifts, Application Examples, Service Life, Medical, AGV/AMR, Laboratory

OVR Series: A Family of Easy-to-Use Small Industrial Robots

Interested in industrial robots but not sure where to start? Learn how Oriental Motor's compact and easy-to-use small industrial robots, robot controllers, and software can help simplify robotic automation.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples, New Product Introductions, XYZ/Cartesian/Gantry

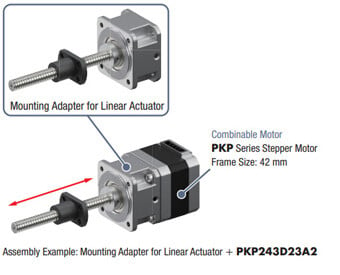

Stepper Motor Linear Actuator Attachment: Easily Convert Stepper Motors to Linear Actuators

The popularity of micro linear actuators has been steadily increasing, driven by the need to increase productivity in confined spaces. To help meet the demand of the miniaturization trend, Oriental Motor has developed a compact linear actuator that can be attached to an off-the-shelf stepper motor.

Topics: Stepper Motors, Robotics, Linear Actuators, VIDEOS, Application Examples, New Product Introductions, Medical

Case Study: How a Compact Electric Gripper Can Help with Articulated Robots

An end effector, such as an electric gripper, is an essential part of industrial robots. More importantly, using the right gripper for the load being transferred prevents damage while improving automation efficiency. In this article, we share how one system integrator has successfully adopted an electric gripper for one of their articulated robots.

Topics: Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Application Examples, Medical, Food & Packaging, Case Studies

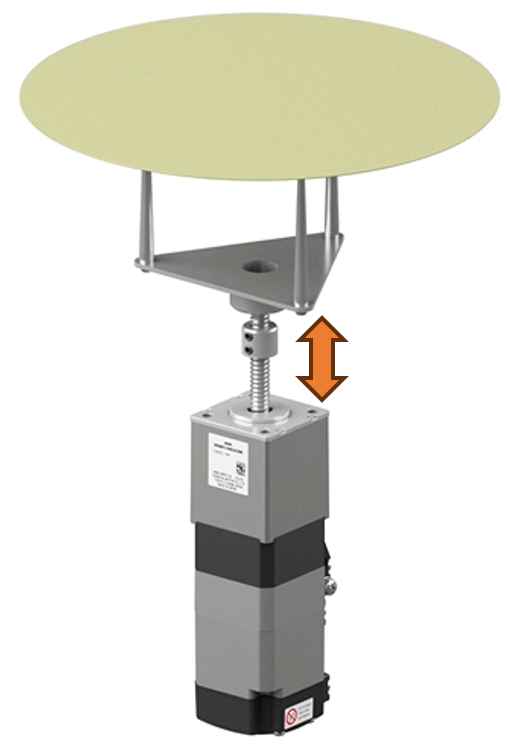

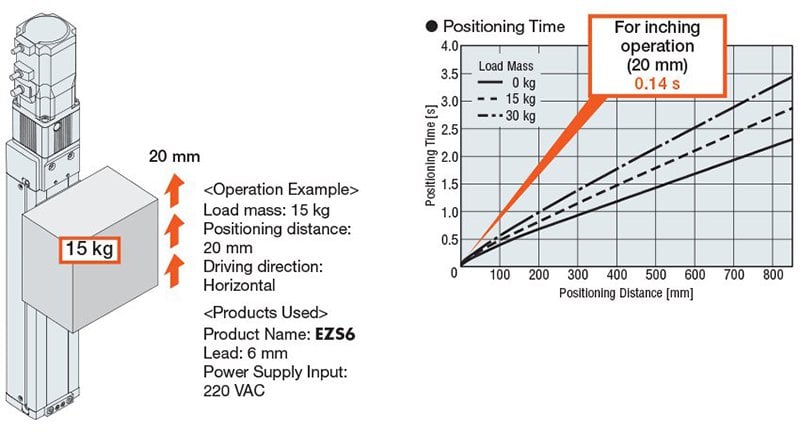

Redefining Precision and Reliability for Wafer Pin Lifters

Downtime is a no no for semiconductor fabs. Even a brief interruption can result in significant financial losses and disruptions in production. In this article, we explain how a linear actuator's built-in precision and reliability can simplify and even improve the design of wafer processing machinery, such as a silicon wafer pin lift.

Topics: Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Vertical Lifts, Application Examples, Wafer Pin Lifters, Semiconductors

Why Electric Actuators Are Better Than Pneumatic Actuators for Packaging Machinery

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS

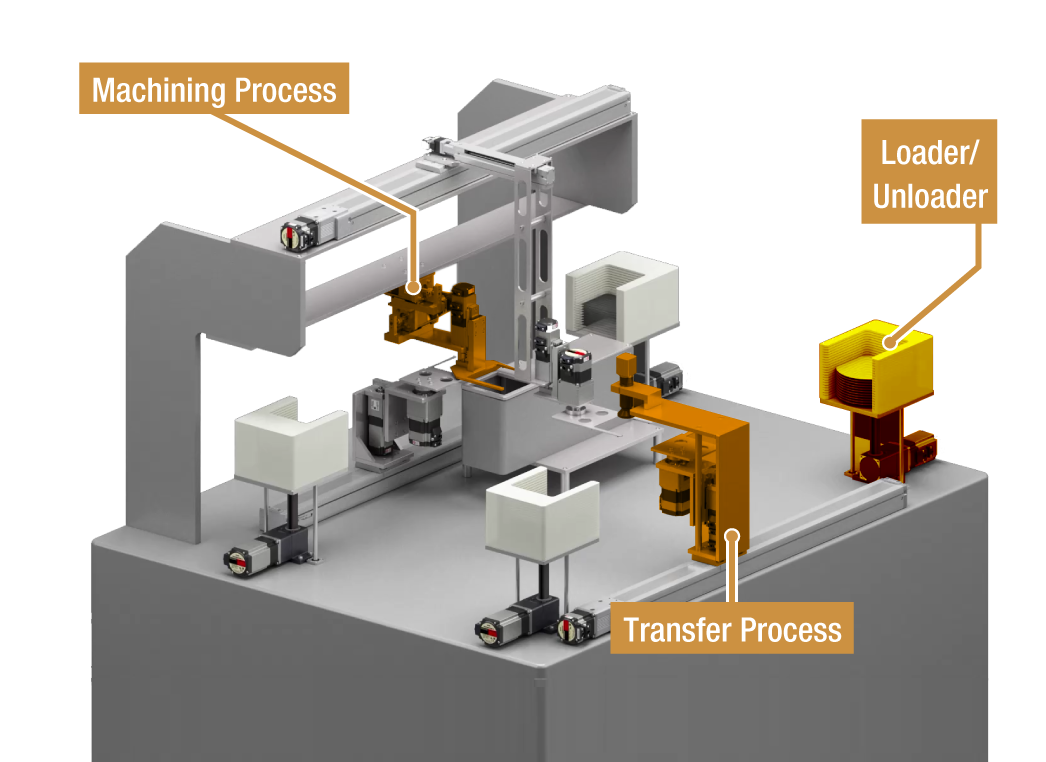

Simplify Wafer Handling Machine Designs with Modular Products from the Same Family

The growing demand for semiconductors, driven by technological advancements like AI, IoT, and robotics, makes it crucial to handle these delicate wafers efficiently and precisely. In this article, we will explain how unified features from a family of motors and actuators can simplify automation for semiconductor wafer manufacturing.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Vertical Lifts, Application Examples, Wafer Handling, Semiconductors

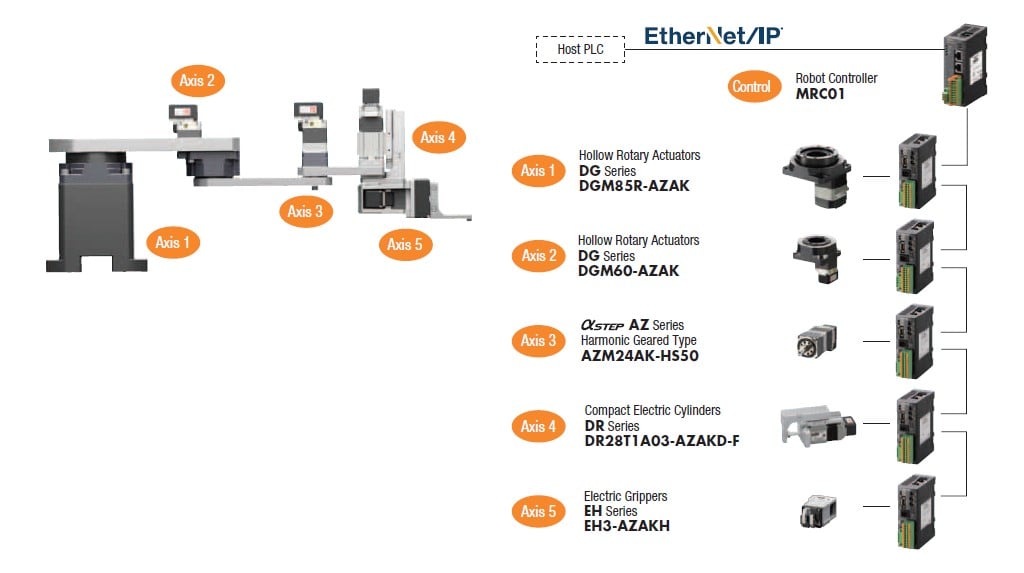

How to Build a SCARA Robot with Off-The-Shelf Products

Robotics automation can be easier to build than you think. Here's an example of how a 5-axis SCARA robot can be built in-house with off-the-shelf products.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Motor Sizing, VIDEOS, Software, Network, Application Examples, Rotary Actuators/Index Tables

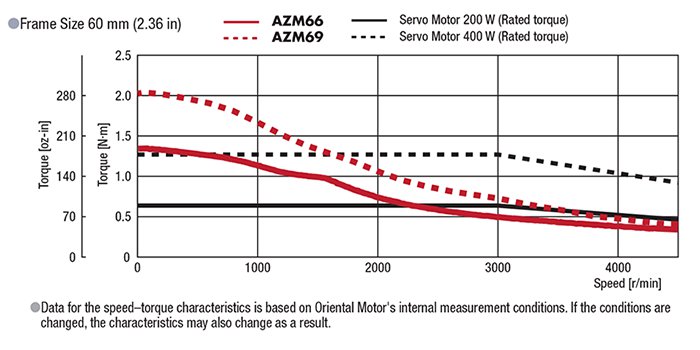

Is There an Option Between Stepper Motors and Servo Motors?

Servo motor systems are expensive but great for demanding applications that require high speed, peak torque, or feedback. Stepper motors are cost-effective but do not offer the peace of mind of feedback. For designs that do not need the bells and whistles of servo motor systems, there is another option.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Servo Motors, Network