Along with the advancement of industrial technology, maintenance methods of motion control components of a machine, such as motors, drives, and sensors, have also evolved.

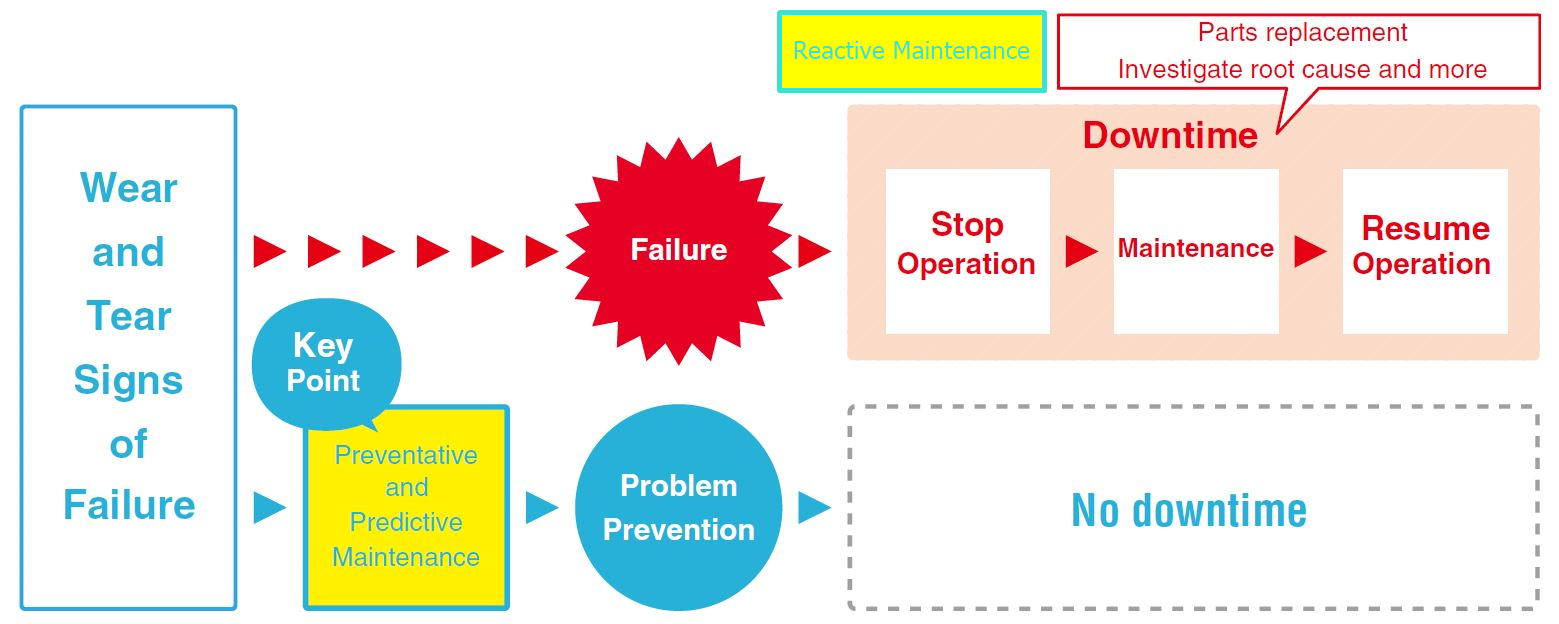

Most of us still use the traditional "reactive" maintenancemethod in many aspects of life, such as replacing a dishwasher in your kitchen. People don't buy a dishwasher until theirs doesn't work anymore. Well, for factories that rely on consistent uptime for production, this wasn't the best strategy. Realizing the need for improvement, maintenance personnel started to estimate life and replace motion control components before they failed. This is called the "preventive" maintenancemethod, which also wasn't a perfect strategy for cost. More recently, with the advancement of IIoT (Industrial Internet of Things) technologies and real-time availability of status data, another method was made possible - the "predictive" maintenance method.