In industrial automation, cooling fans are used to cool electronics so that equipment can last longer. However, knowing which type of fan to apply to your machine design can be tricky. In this article, I explain how fans affect the life of electronics and compare the characteristics of the 3 most common types of cooling fans.

Table of Content

- Why are cooling fans necessary?

- What types of cooling fans are used for industrial automation machinery?

- Axial Fans - For General Purpose (Most Common)

- Centrifugal Blower - For Highest Static Pressure

- Cross Flow Fans - For Wide Area Cooling

- Summary of Key Differences

Why are cooling fans necessary?

Technically, a cooling fan pushes air around electronic components, thereby releasing energy (heat) to reduce operating temperature. This reduction in temperature has numerous advantages, including extended lifespan, reduced maintenance, decreased downtime, improved production throughput, and increased profitability for the company.

|

FYI: Service Life of a Circuit Product |

|

|

The service life of a circuit product, such as a stepper motor driver, is determined by the aluminum electrolytic capacitor inside the driver. Our circuit products are designed to reach 5 years minimum when the product is used continuously under an ambient temperature of 40°C (excluding certain products). As shown in the reference graph to the right, a temperature rise of 10°C reduces the life of an aluminum electrolytic capacitor to half, while a temperature drop of 10°C will extend the life ot twice as long. |

Now that we understand the importance of cooling fans, let's review the characteristics of the 3 main types of cooling fans used in industrial automation and learn how they're applied in machine or enclosure designs.

What types of cooling fans are used for industrial automation machinery?

The 3 main types of cooling fans used for industrial automation are axial fans, centrifugal blowers, and cross flow fans.

Axial Fans - For General Purpose (Most Common)

|

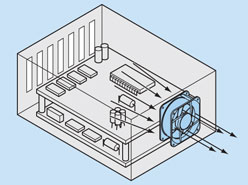

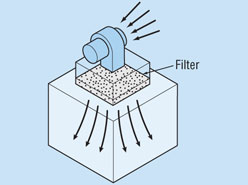

The propellers (fan blades) located in the circular flow path between the cylindrical hub and casing are used to force-feed air in order to generate air flow in the direction of the axis of rotation. Since air flows along the axis of rotation, the structure is kept compact. Capable of generating a large air flow, axial fans are suited for applications requiring ventilation cooling where the entire space inside the equipment must be cooled. |

Axial fans are the most common type of fan used in industrial automation machinery. The large air flow and low-pressure characteristics of axial fans are suitable for ventilation and cooling of electronic components inside various types of enclosures.

Application Examples

|

Device Ventilation and Cooling |

Cooling Densely Mounted Devices |

|

|

Most of Oriental Motor's cooling fans are built with die-cast aluminum for strength and durability. We assemble either a permanent-split-capacitor type AC induction motor or a brushless DC motor with well-balanced fan blades designed for low noise. Fans with permanent-split-capacitor type AC induction motors are more efficient than fans with shaded-pole type AC motors. These fans also include various built-in features, such as low-speed/stall alarm, long-life, and splash-proof types.

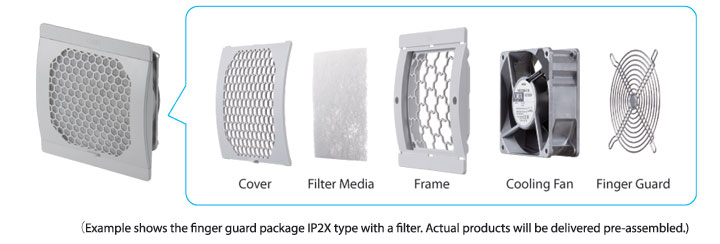

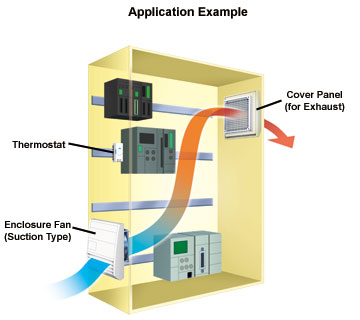

Enclosure fans are axial fans with a pre-assembled cover, filter media, frame, and finger guard. These add-ons improve the IP (ingress protection) rating of the axial fan to IP2X, IP4X, IP43 or IP55 and make the fan much easier to install onto an enclosure. Not only does an enclosure fan cool the electronic components inside the enclosure, but it also keeps dust and water out.

|

|

| FYI: Special promotion on MRS Series 200 mm frame size axial fans | ||

This axial fan provides reliable cooling for heat-sensitive systems, including data infrastructure such as server rooms and data centers, as well as power electronics like inverters and power supplies. The promotional price is almost 50% off retail. Please click the image below for more information about this great deal. |

||

Centrifugal Blower - For Highest Static Pressure

|

The centrifugal force of the cylindrically positioned runner (forward-facing blades) generates rotational flows roughly perpendicular to the axis of rotation. The generated rotational flows are aligned in the same direction through scroll action, and the pressure rises accordingly. Since the exhaust outlet is reduced to focus air in a specified direction, these blowers are used for spot cooling. The static pressure is also high, which makes them a suitable choice when cooling equipment through which air cannot flow easily or when blowing air using a duct. |

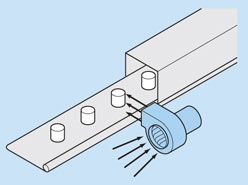

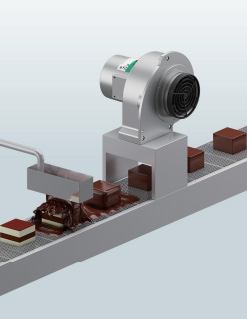

Designed for spot cooling, centrifugal blowers offering moderate to high air flow and high static pressure. They are suitable for applications that require concentrated cooling, such as cooling workpieces following heat treatment. The high static pressure of centrifugal blowers allows cooling even with filters that are subject to significant pressure losses.

Application Examples

| Air-Blow Cooling or Drying | Cooling with High Static Pressure |

|

|

Oriental Motor's newest centrifugal blower is the MB Series S Type.

|

The MB Series S Type AC input centrifugal fans provide large static pressure and can produce directional air flow ideal for cooling, drying or forcing air through duct work. Available in 2 frame sizes 3.94 in. (100 mm) and 4.72 in. (120 mm) with a maximum air flow of 184 CFM (5.2 m3/min) and a maximum static pressure of 1.81 inH2O (450 Pa).

|

|

|

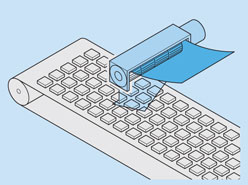

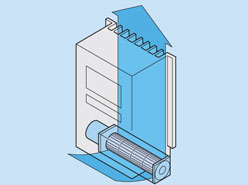

A cross flow fan has an impeller similar to that of a centrifugal blower, but both sides of the fan are covered with side panels and thus no air enters from the axial direction. As a result, air flows that pass through the impeller are generated. Cross flow fans utilize these air flows. Since a long cylindrical impeller is used to blow air, air travels over a wide width. Also, uniform air can be achieved because air is exhausted sideways along the circumference of the impeller. |

Cross flow fans offer moderate air flow, low pressure, and are suitable for cooling a wide, narrow area. They can be used for uniform cooling or drying of parts on a conveyor or cooling electronic components in a long and thin enclosure. They are the least common of the 3 types of common cooling fans, but they can be ideal for the right applications.

Application Examples

| Uniform Cooling or Drying | Cooling of Long and Thin Space |

|

|

Prefer to watch? Here's a video that introduces the 3 types of cooling fans and their intended applications.

|

Summary of Key Differences

|

The differences in air flow and static pressure are shown in the graph below.

|

Comparison of Axial Fans, Centrifugal Blowers, and Cross Flow Fans

|

Feature

|

Axial Fans | Centrifugal Blowers | Cross Flow Fans |

| Air Flow Direction | Parallel to the axis (linear flow) | Air enters axially, exits radially at 90° | Air flows straight through, perpendicular to axis |

| Static Pressure | Low pressure, high volume | Moderate to high pressure, moderate volume | Low pressure, wide and uniform airflow |

| Typical Applications | General ventilation, cooling electronics, HVAC, tunnel ventilation | HVAC, dust collection, pneumatic conveying, industrial processes | Electronics cooling, HVAC, convection heating, display cases |

| Efficiency | High for low-pressure, high-volume needs | High efficiency for pressure applications | Efficient for moving air across wide surfaces at low pressure |

| Noise Level | Can be higher at high speed | Generally quieter due to enclosed design | Quiet operation, suitable for noise-sensitive areas |

| Design/Form Factor | Compact, simple, multiple blade options | Enclosed housing, impeller with curved blades | Long cylindrical impeller, compact for wide airflow |

| Energy Consumption | Energy efficient for high-volume, low-resistance | Efficient at higher pressures, may use more energy for high resistance | Lower power consumption for similar airflow |

| Advantages | High airflow, compact, simple design | High pressure, quiet, durable | Uniform airflow, quiet, compact |

| Disadvantages | Limited pressure, sensitive to system changes, can be noisy | Larger size for same airflow, more complex | Lower max airflow/pressure |

Still not sure which fan to use?

Related Articles: