While optical encoders have long been the standard, magnetic encoders are emerging as a compelling alternative due to their durability, cost-efficiency, and versatility. In this article, we’ll compare the pros and cons of both encoder technologies and explain why Oriental Motor's magnetic encoders deserve a closer look for a wider range of applications.

What's covered by this article?

- What is an Encoder?

- How Do You Interpret the Encoder Pulse Signal?

- How Does An Optical Encoder Work?

- How Does a Magnetic Encoder Work?

- Comparison: Optical Encoders vs Magnetic Encoders

- Oriental Motor Magnetic Encoders Lineup

- For Tracking Motor Shaft Position

- For Direct Tracking of Rotary Mechanisms

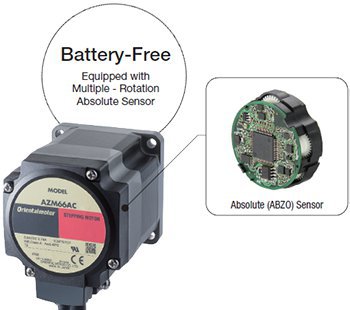

- For Multi-Turn Absolute Position Control

What is an Encoder?

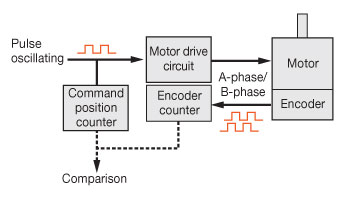

Let's review a little bit. In the simplest terms, an encoder is an electromechanical sensor that tracks the position, speed, or direction of a motor shaft by a pulse train signal. This pulse train signal can be used by a PLC or dedicated controller to verify the actual position of a motor shaft and to make adjustments.

Encoders can be integrated with the rear shaft of a stepper motor, a servo motor, a brushless motor, or even a rotating mechanism like an index table. Closing the loop with encoders significantly enhances the motor performance and capabilities by enabling position feedback, misstep detection, performance enhancements, and/or predictive maintenance.

How Do You Interpret the Encoder Pulse Signal?

- The number of pulses determines how many steps the motor shaft has rotated.

- The frequency of pulses (Hz) determines how fast the motor shaft is rotating.

- The rises and falls of the A-phase and B-phase pulses determine which direction the motor shaft is rotating.

How Does An Optical Encoder Work?

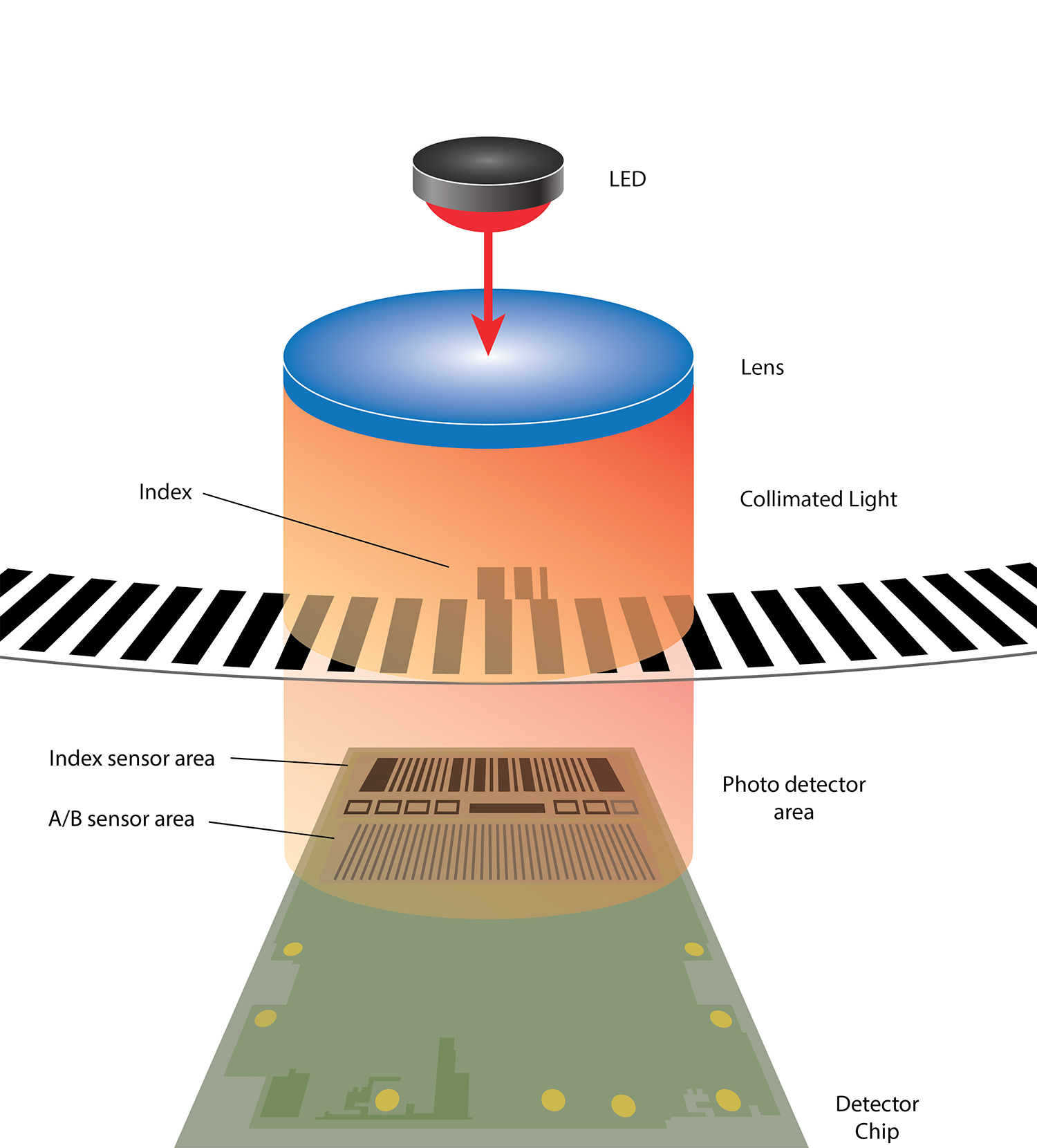

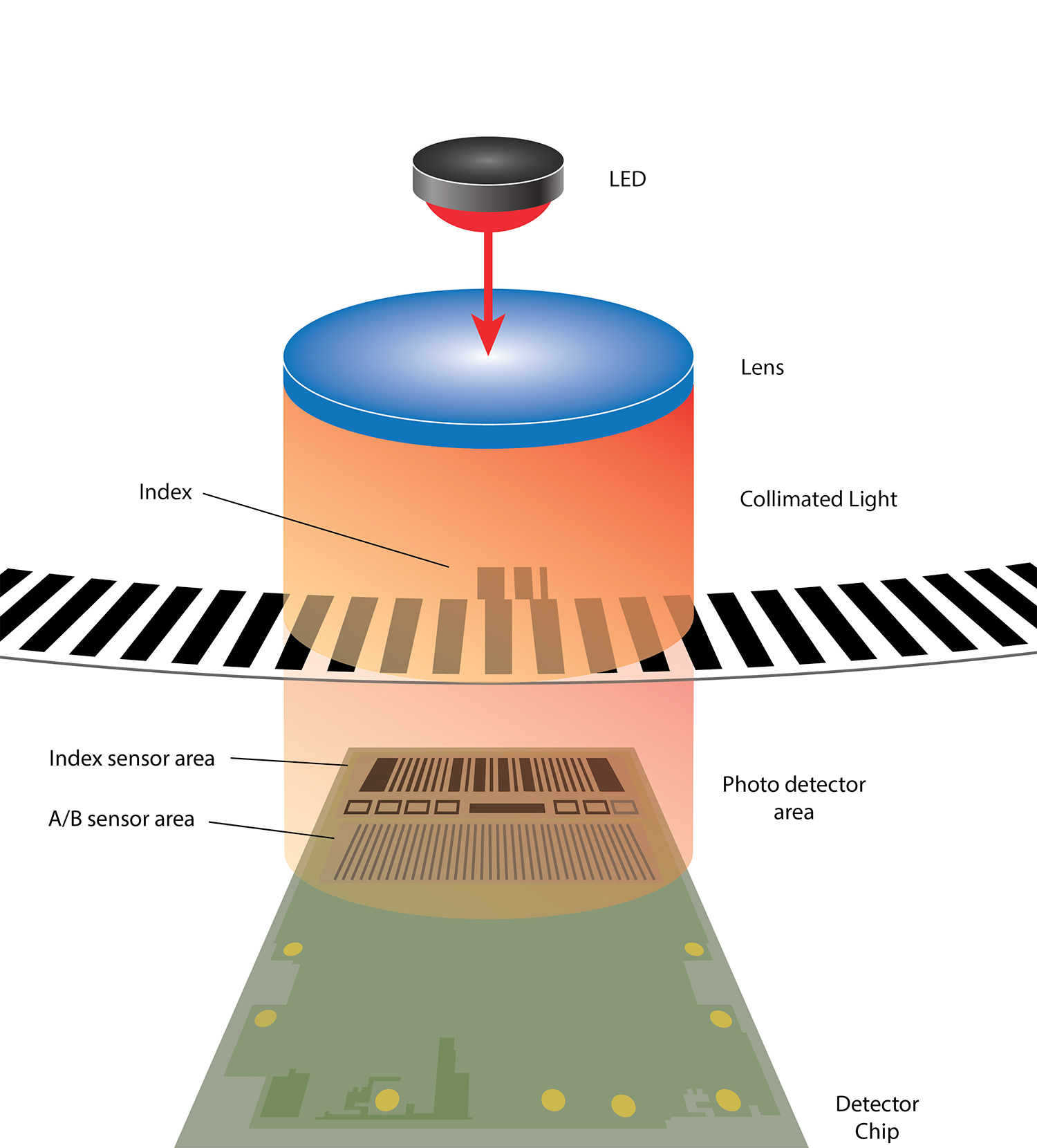

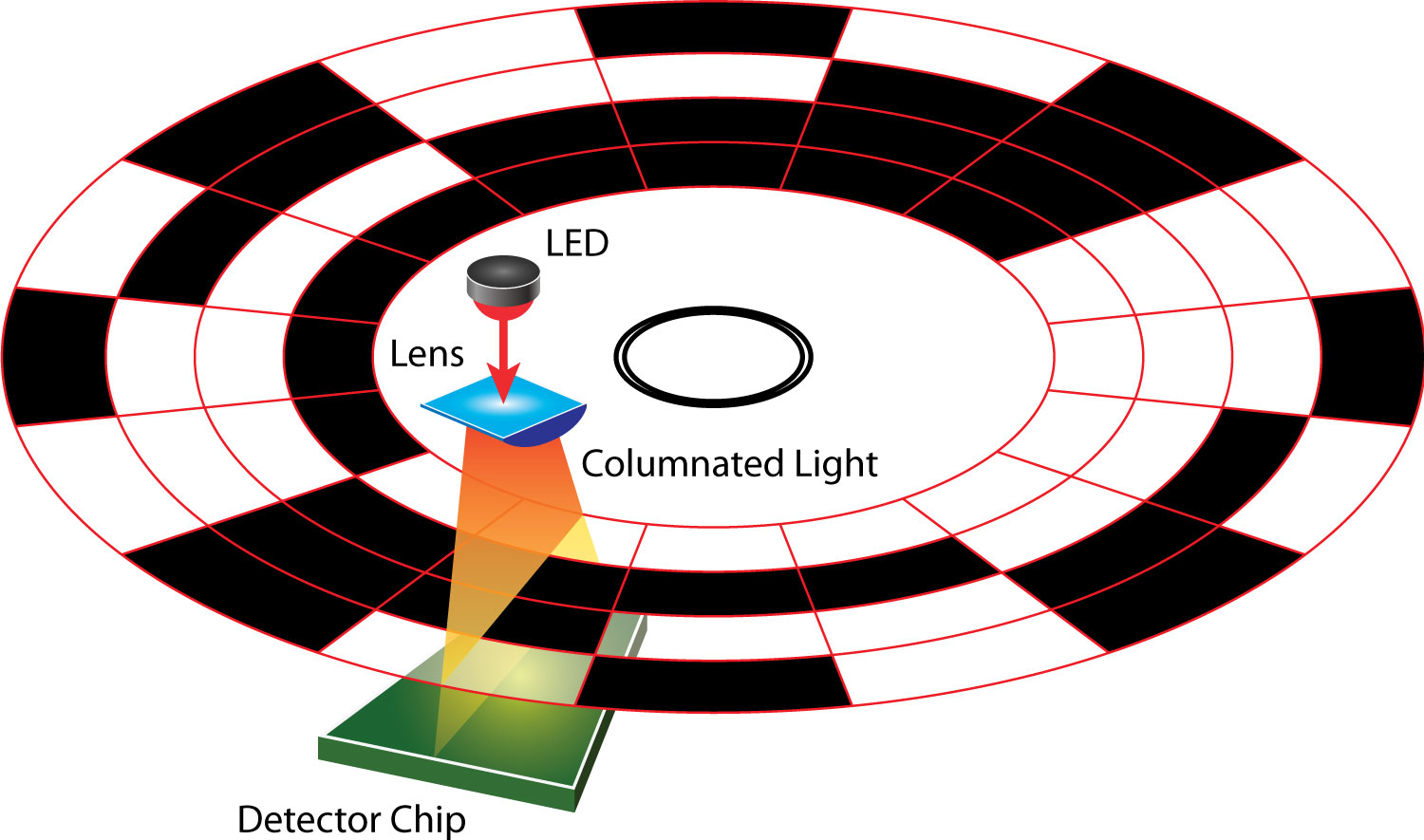

The most common type of encoder in the market is the optical encoder, which was actually invented by a company called the Baldwin Piano Company (later BEI Electronics) around 1955. An optical encoder is an electromechanical sensor that uses a light emitter, a light receiver, and a coded wheel to generate light pulses as the motor shaft turns. The pulses are typically output to a PLC or a dedicated controller for position verification and correctional adjustments.

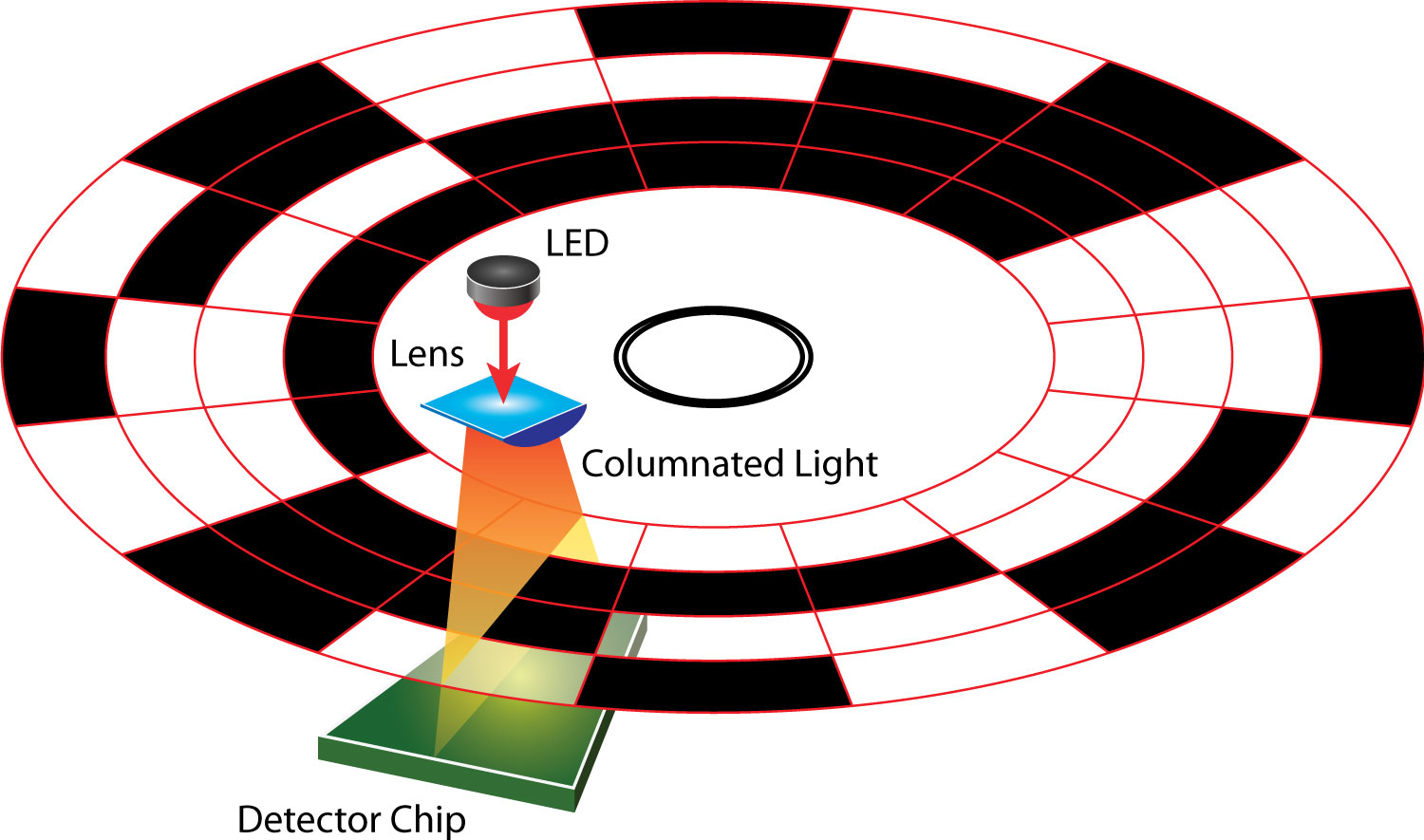

There are 2 types of optical encoders: incremental and absolute. Incremental encoders have one track of slits on the code wheel to provide 1 bit of data, while absolute encoders have multiple tracks of slits on their code wheel to convey multiple bits of data.

| Incremental Encoder |

Absolute Encoder |

|

|

Source: https://www.usdigital.com/blog/difference-incremental-vs-absolute-encoders

Incremental optical encoders measure movement by generating pulses as the motor shaft turns. These pulses tell the system how far and how fast the shaft is moving, but they cannot track the exact position since each position on the code wheel is not unique. If power is lost, the system forgets where it was and needs to reset by performing a homing routine.

Absolute optical encoders, on the other hand, always know the exact position. Each position on the code wheel uses a unique pattern that gives a specific digital code or data, so the system can instantly read the shaft’s location at any time. Due to the added complexity in design, absolute optical encoders are more expensive to make.

How Does a Magnetic Encoder Work?

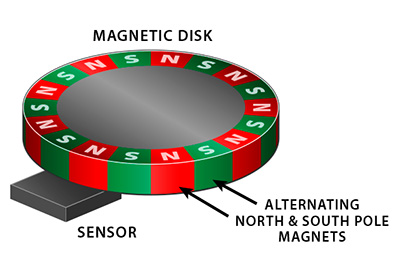

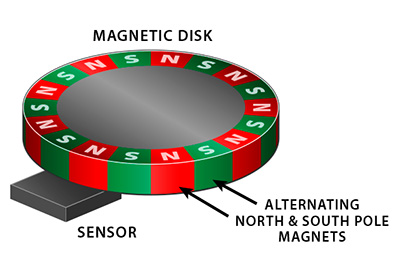

Compared to optical encoders, magnetic encoders do not use a light emitter or a light receiver but still use a code wheel and a magnetic sensor. Instead of slits, the code wheel has alternating north and south pole magnets on the outer edge. To track movement, the magnetic sensor senses changes in magnetic polarity when the north and south poles pass by.

Hall-effect and magnetoresistive technologies are both used to detect magnetic fields.

Hall-effect sensors detect the voltage generated when a magnetic field is applied perpendicular to the current flow in a conductor. They are widely used for position and speed sensing due to their simplicity, cost-effectiveness, and ability to detect both static and dynamic magnetic fields. However, they typically offer lower resolution and sensitivity compared to magnetoresistive sensors, so they're typically used with brushless DC motors for variable speed applications.

Magnetoresistive sensors, on the other hand, rely on changes in electrical resistance that occur when magnetic domains in a material align in response to an applied magnetic field. This technology offers higher sensitivity, improved resolution, and the ability to detect smaller changes in magnetic field strength. It’s especially useful in precision applications with stepper motors or servo motors. This is the technology we use on Oriental Motor's products.

Comparison: Optical Encoders vs Magnetic Encoders

Since both incremental and absolute optical encoders use light, a consistent power supply is a must when maintaining position data. Backup batteries are required to maintain position data to avoid disruptions during power failures. Optical encoders offer higher resolution but are also more expensive than other types of encoders, such as magnetic encoders.

Magnetic encoders typically offer lower resolution than optical encoders, but are more cost-effective and robust, as they can operate in more humid, dusty, or dirty environments. However, magnetic encoders may not function well in environments with strong magnetic interference. Since there's no need to power the light emitter and receiver, the magnetic encoder also uses less power than an optical encoder.

With both optical encoders and magnetic encoders, the resulting output is the same; as both types of encoders output digital pulses to a PLC or host controller for verifying the motor shaft position in real-time or for making adjustments.

Here's a table that summarizes the differences between optical encoders and magnetic encoders:

|

Type

|

Optical Encoders

|

Magnetic Encoders

|

|

Sensing Principle

|

Uses light and photodetectors

|

Uses magnetic fields and Hall-effect sensors

|

|

Resolution & Accuracy

|

Very high; ideal for precision tasks

|

Moderate; sufficient for general positioning

|

|

Environmental Tolerance

|

Sensitive to dust, oil, and vibration

|

Highly resistant to contaminants;

sensitive to strong magnetic fields

|

|

Durability

|

Less robust in industrial environments

|

Excellent for rugged and outdoor applications

|

|

Cost

|

Typically higher due to precision optics

|

Generally more cost-effective

|

|

Typical Applications

|

Robotics, CNC machines, lab automation

|

Conveyors, motors, outdoor machinery

|

Oriental Motor offers both optical encoders and magnetic encoders. Optical encoders are included on certain products, such as PKP Series high torque stepper motors (unipolar type), BXII Series brushless DC motors, and custom products. Hall-effect sensors are equipped on other brushless DC motors. Please read on to learn about our magnetic encoder products.

Oriental Motor's Magnetic Encoders Lineup

Oriental Motor offers 3 types of magnetic encoders:

- Preassembled encoders on PKP Series high torque stepper motors (incremental)

- Standalone rotary encoders (incremental)

- Multi-turn battery-less mechanical absolute encoders

☑️ For Tracking Motor Shaft Position

PKP Series High Torque Stepper Motors (Encoder Type)

Choose the Encoder Type PKP Series for high torque stepper motors with a preassembled incremental magnetic encoder. These magnetic encoders are smaller and lighter than optical encoders because they do not require complex optical components like light sources or photodetectors.

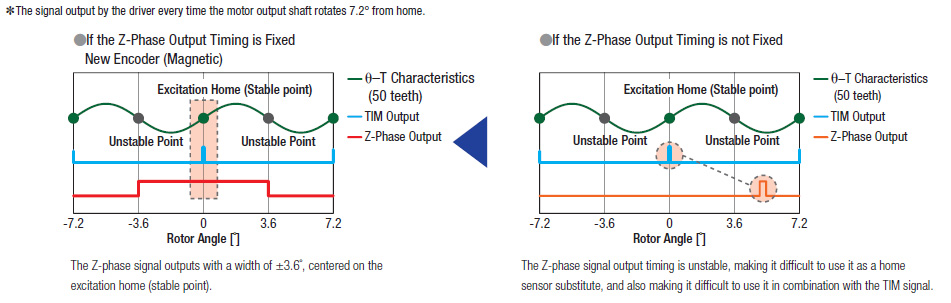

Preassembled encoders are available on PKP Series frame sizes from 20 mm to 60 mm (round shaft or geared versions). Resolutions from 200 to 1,000 PPR are available. A-phase, B-phase, and Z-phase 3-channel outputs are available with voltage (TTL) or line driver output circuit type. Angular accuracy is ±0.36°. Connect the pulse train signal to your PLC or host controller for position verification and correction.

☑️ For Direct Tracking of Rotary Mechanisms

Rotary Encoders

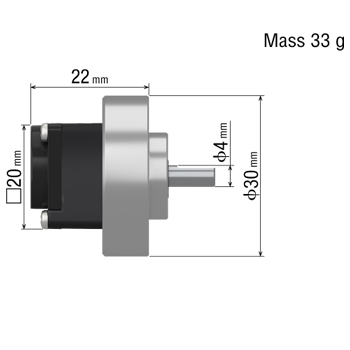

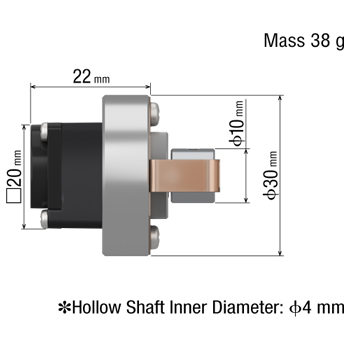

Instead of having a magnetic encoder on the motor, we also offer magnetic encoders as standalone products. Since these rotary encoders are small, thin and lightweight, they can be installed in tight spaces.

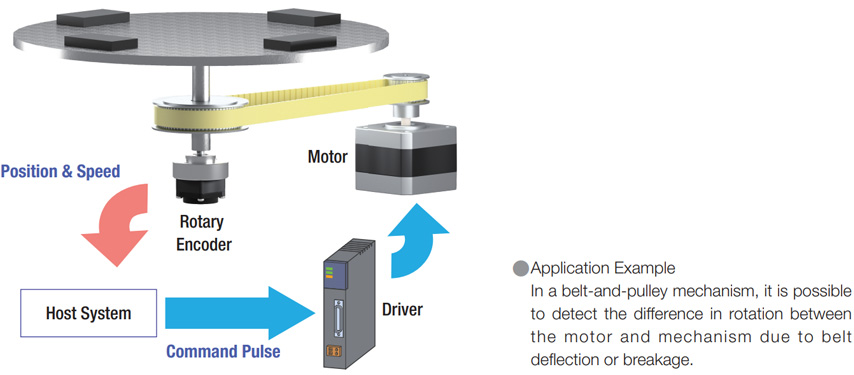

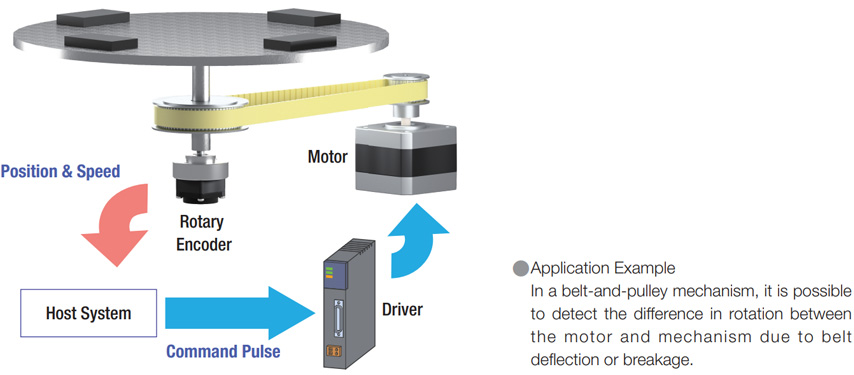

Why do we offer standalone encoders? I'm glad you asked. Standalone encoders can be installed at the mechanism level to track the load position directly rather than tracking the motor shaft position. With this method, you can eliminate mechanical errors that occur externally to the motor. For example, in a belt-and-pulley mechanism, the elasticity or breakage of the belt can add extra encoder pulses and introduce errors. If gears replaced the belt, you would have backlash between the gear teeth.

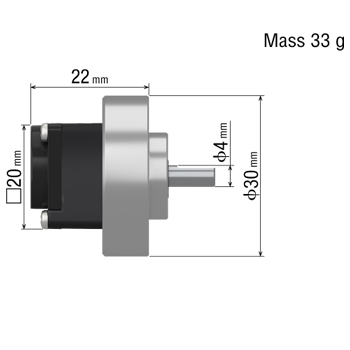

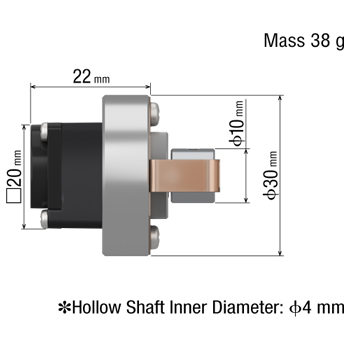

| Round Shaft Type |

Hollow Shaft Type |

|

|

Application Example

Oriental Motor offers standalone rotary encoders in both round shaft and hollow shaft types. Output circuit types include multiple options: voltage, line driver, or open collector. Higher encoder resolutions are available from 100 to 4,000 P/R. These rotary encoders are available in round shaft type or hollow shaft type with voltage, line driver, or open collector output.