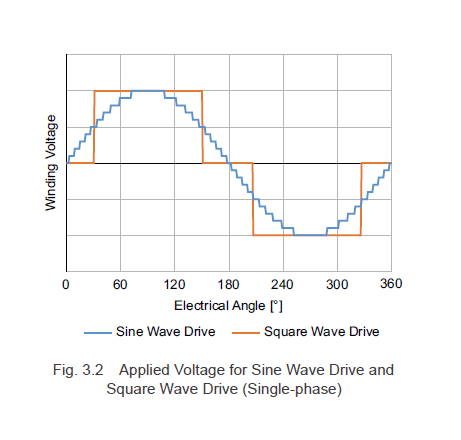

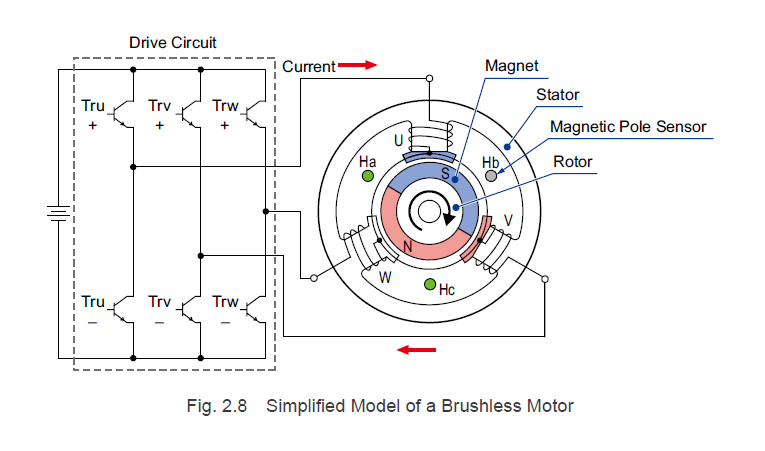

There is a close relationship between the drive system and brushless motor characteristics, and various methods have been used to improve the controllability and characteristics of motors. In this post, we will explain two typical drive systems: square wave drive and sine wave drive.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Technical Manual Series: Brushless Motor Drive Systems

Topics: Speed Control, BLDC Motors, Technical Manual Series

Technical Manual Series: Main Components of Brushless Motors

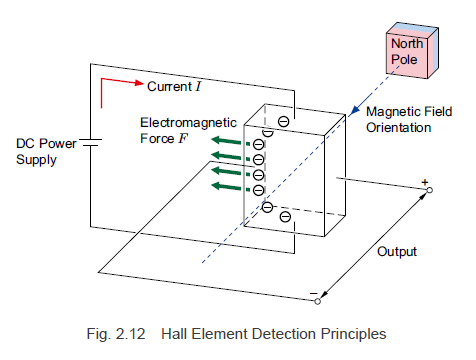

In part 4, we will explain the main components of brushless motors: feedback, magnetic field, and permanent magnets.

Topics: Speed Control, BLDC Motors, Technical Manual Series

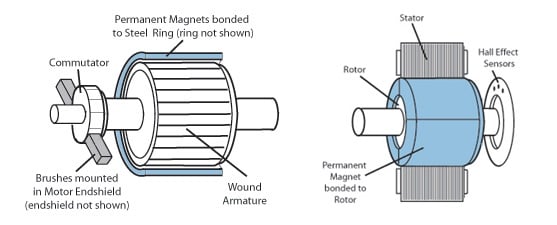

Technical Manual Series: Brushless Motor Structure and Rotation Principles

In part 3, we will explain the differences in the structure and rotation principles of brushless motors, and compare them to brushed DC motors and AC motors.

Topics: Speed Control, BLDC Motors, Technical Manual Series

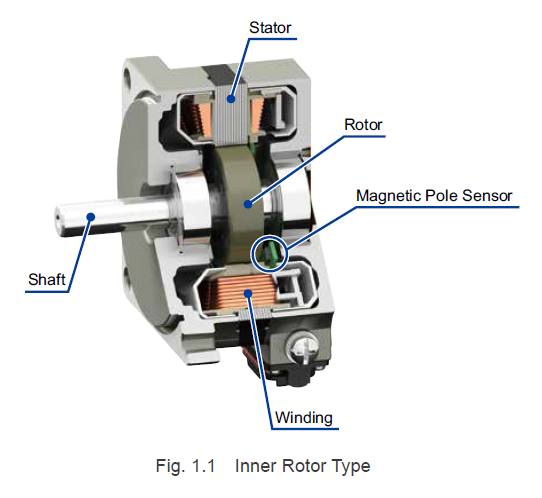

This is part 1 of the Technical Manual Series for brushless motors, which explains the three main types of brushless motors: inner rotor type, outer rotor type, and disk rotor type.

Topics: Speed Control, VIDEOS, BLDC Motors, Technical Manual Series

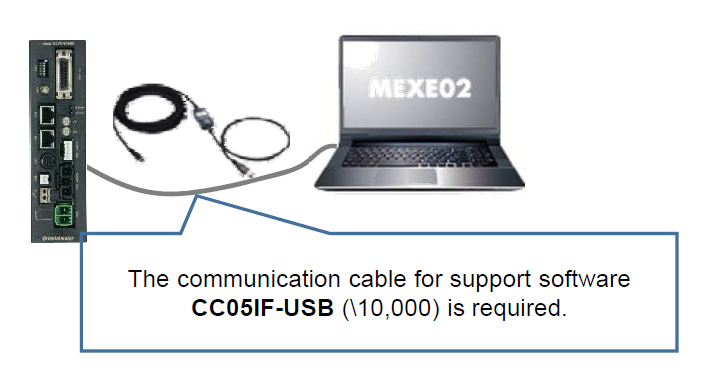

The BLV Series is one of two DC-input brushless motor speed control systems we offer. While a brushless motor with hall-effect sensor feedback provides constant torque, wide speed range, and speed regulation, the BLV driver offers unique functions designed for mobile robots, such as low battery operation and ramp operation.

Topics: Robotics, Speed Control, BLDC Motors, Software, Network, Troubleshooting

Speed Control Basics: VFD or Triac for AC Induction Motors?

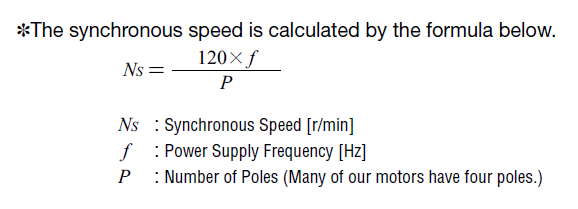

When a voltage is applied to an AC induction motor, it runs at a certain speed. Variable speed requirements for AC induction motors are typically fulfilled by a 3-phase motor and an inverter or VFD. This blog post also introduces another option.

Topics: AC Motors, Speed Control, Motion Control Basics, Conveyors

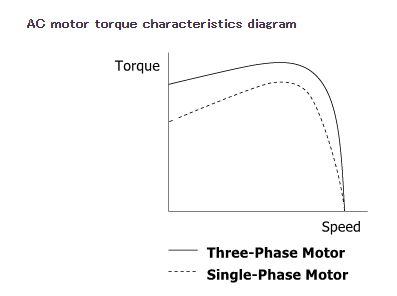

Why Three-Phase Motors Are Better for Instantaneous Forward/Reverse Operation

The differences between single-phase and three-phase AC induction motors don't stop with the input power supply. There are a few reasons why three-phase AC induction motors work better for an instantaneous forward/reverse operation.

Topics: AC Motors, Speed Control

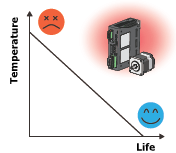

Knowing how to use a product properly can make a huge difference in its performance and life. For example, knowing how to maintain cast iron pans properly can make them last longer. With electric motors, understanding the factors that affect motor life is the first step to extending life and decreasing costs in the long run.

Topics: AC Motors, Stepper Motors, Linear Actuators, Speed Control, Servo Motors, Service Life

Brush DC Motors vs Brushless DC Motors: Which is Better?

My first experience using DC motors was for a small elevator for a science project back in school. Although I had no idea, that day would become only the first day of my experience with motors.

Topics: Speed Control, VIDEOS, BLDC Motors

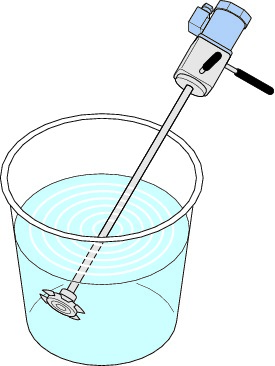

Minimizing the Effect of Load Fluctuations for Mixers

The viscosity change in liquids can vary the torque required for mixing. For AC asynchronous motors such as AC induction motors, the rated speed is affected by load torque fluctuations, which may cause inconsistency in the final product. Is there a better motor for the job?

Topics: Speed Control, VIDEOS, BLDC Motors, Gearheads, Washdown, Application Examples