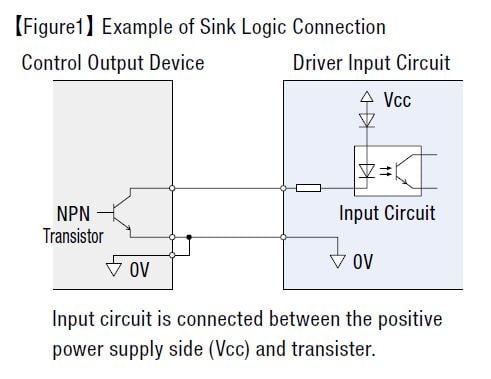

For someone who has never had experience wiring I/O for motion control, it can be scary the first time. If devices are not wired correctly, it can cause a range of issues from a motor simply not doing what's expected to irreversible product damage. I still get that nervous feeling before I press the START button on a demo. Murphy's Law, anyone?

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Control Basics: The Difference Between Sink and Source Logic

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, BLDC Motors, Servo Motors, Motion Control Basics

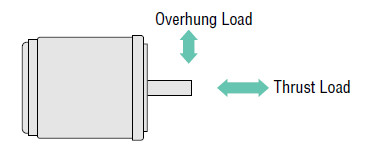

Motor Sizing Basics Part 4 - How to Calculate Radial Load and Axial Load

Besides load torque, acceleration torque, speed, and load inertia, overlooking certain sizing parameters during the motor sizing process can literally make or break your machine.

Topics: AC Motors, Stepper Motors, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Servo Motors, Motion Control Basics

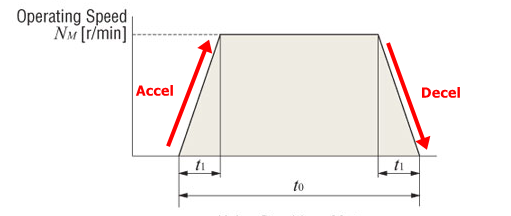

Motor Sizing Basics Part 3: How to Calculate Speed, Acceleration Torque, and RMS Torque

Now that we understand the calculations behind load torque and load inertia, we're a little closer to motor selection. You might be wondering why I separated load torque and acceleration torque calculations. That's because in order to calculate for acceleration torque, load inertia and speed must be calculated first.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Motion Control Basics

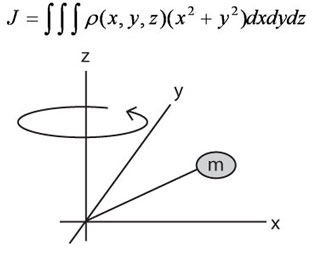

Motor Sizing Basics Part 2: How to Calculate Load Inertia

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics

Motor Sizing Basics Part 1: How to Calculate Load Torque

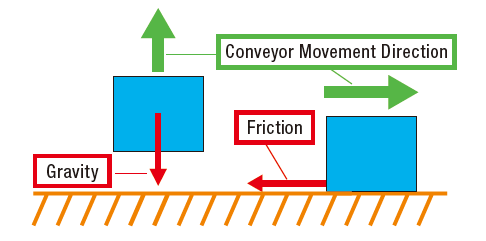

Proper sizing of a motor requires that 3 criteria must be met: torque, load inertia, and speed. For the first part of this Motor Sizing Basics series, I will be explaining what load torque is, how to calculate it for specific application examples, and how it fits into the torque requirement for the application.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Rotary Actuators/Index Tables, Motion Control Basics, Conveyors

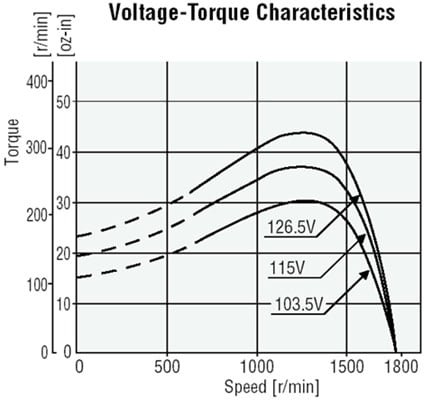

Eliminate Motor Speed Fluctuations Caused By Input Voltage or Load Variance

An AC motor can be simple to use, but its speed changes according to the size of the load or amount of voltage supplied. For an application where keeping a uniform speed is important, there is another type of motor that can improve performance.

Topics: AC Motors, Speed Control, VIDEOS, BLDC Motors, Application Examples

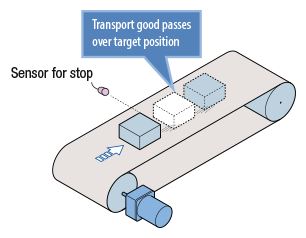

Are you using motors for a start/stop conveyor or similar application? While AC motors are a common choice for conveyors, there is a unique speed control motor solution available that could improve stop accuracy as well as reduce footprint and cost of machine designs.

Topics: AC Motors, Stepper Motors, Speed Control, VIDEOS, Application Examples, Conveyors

What motors do you use for pumps? For variable speed pump applications that typically use 3-phase AC induction motors with variable frequency drives (VFDs), there is another type of motor that can transfer fluids more consistently and help reduce footprint.

Topics: AC Motors, Speed Control, VIDEOS, BLDC Motors, Pumps, Application Examples, Medical

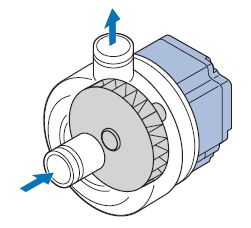

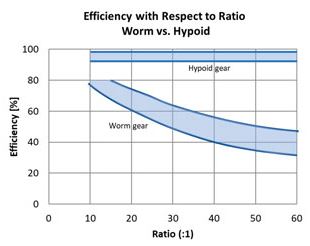

Right Angle Gearheads: Why are Hypoid Gears Better Than Worm Gears?

As efficiency becomes increasingly important, another type of gear is being adopted for right-angle gearheads over the common worm gears.

Topics: AC Motors, Speed Control, BLDC Motors, Gearheads

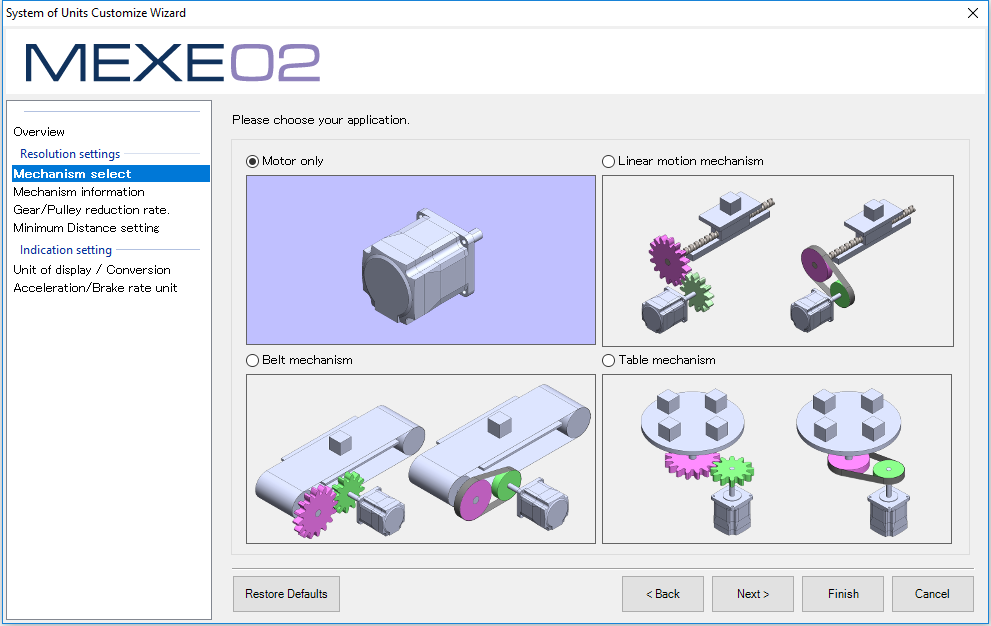

Introduction to the MEXE02 Universal Motion Control Support Software

The MEXE02 support software is a universal motion control and monitor software used with multiple products from Oriental Motor, such as the AZ Series, RK2 Series, BLE2 Series, and BX2 Series. This article is useful for first-time users to gain a quick understanding of the software and what it can do.

Topics: Stepper Motors, Linear Actuators, Speed Control, VIDEOS, BLDC Motors, Software, Servo Motors