At Oriental Motor, continuous improvements are part of our process. This article takes a deep look at functional updates of our popular BLH Series drivers, how they differentiate from existing drivers, and how they can improve functionality and performance.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Improve BLDC Motor Performance With Updated Drivers

Topics: Torque Limit (Push Motion, Tension Control), Robotics, Speed Control, VIDEOS, BLDC Motors, Software, Bottle Capping, AGV/AMR

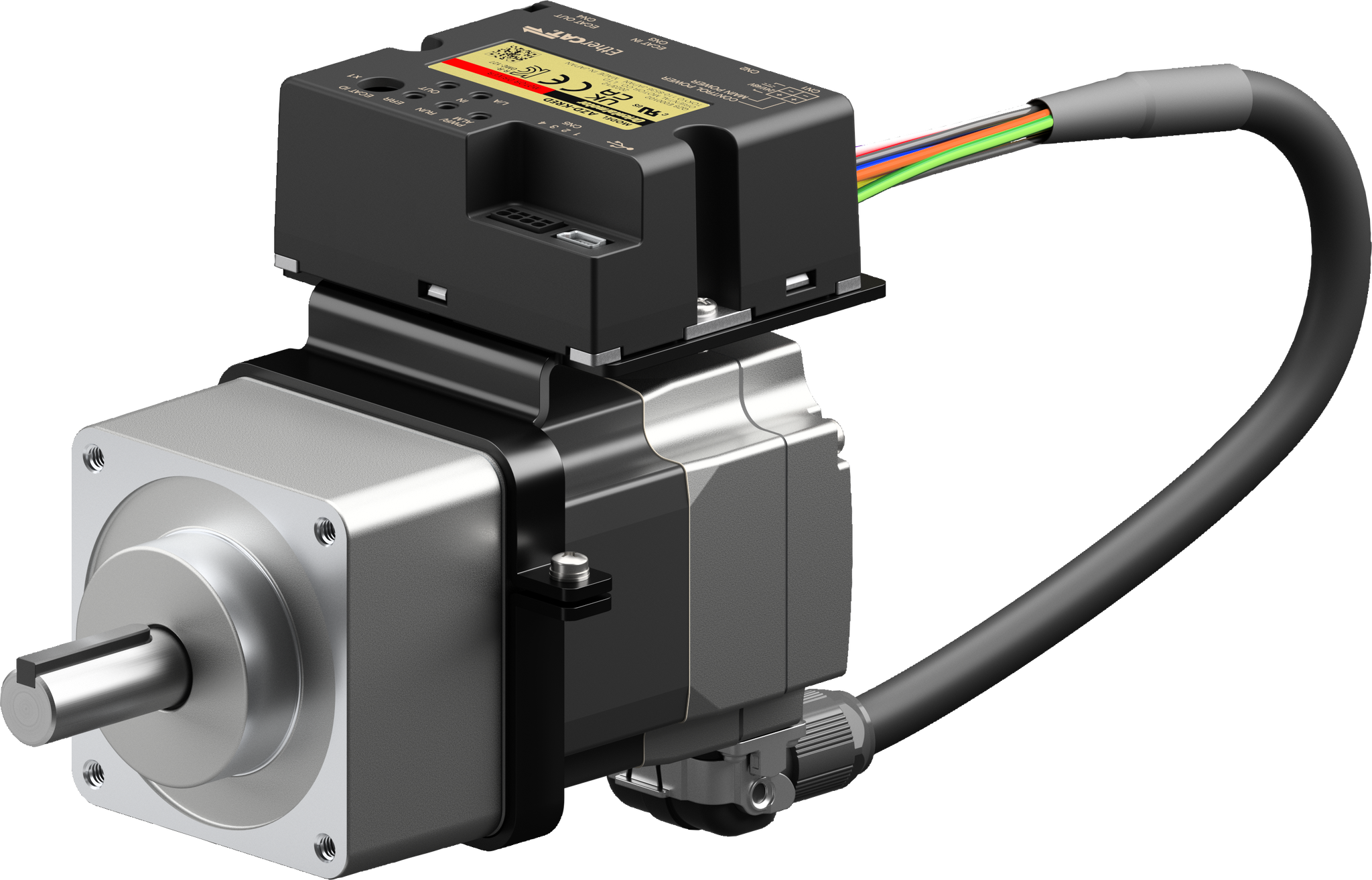

All-in-One Hybrid Step-Servo Solution for Compact Precision Automation

Modern automation increasingly demands higher reliability, faster time-to-build, and easier scalability in a smaller package. If you’ve ever wished you had an easy button for motion control, Oriental Motor’s αSTEP Hybrid Step-Servo AZ Series product family lets you build your own compact, modular motion control solution by choosing off-the-shelf products.

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, New Product Introductions

Boosting Throughput with Omnidirectional Motion: Introducing Full 360° Type SCARA Robots

In high-volume manufacturing, every second matters. Although traditional SCARA robots have been a staple in assembly and material handling, their limited rotational range can often cause delays that can keep them from maximizing throughput.

Topics: Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Application Examples, New Product Introductions

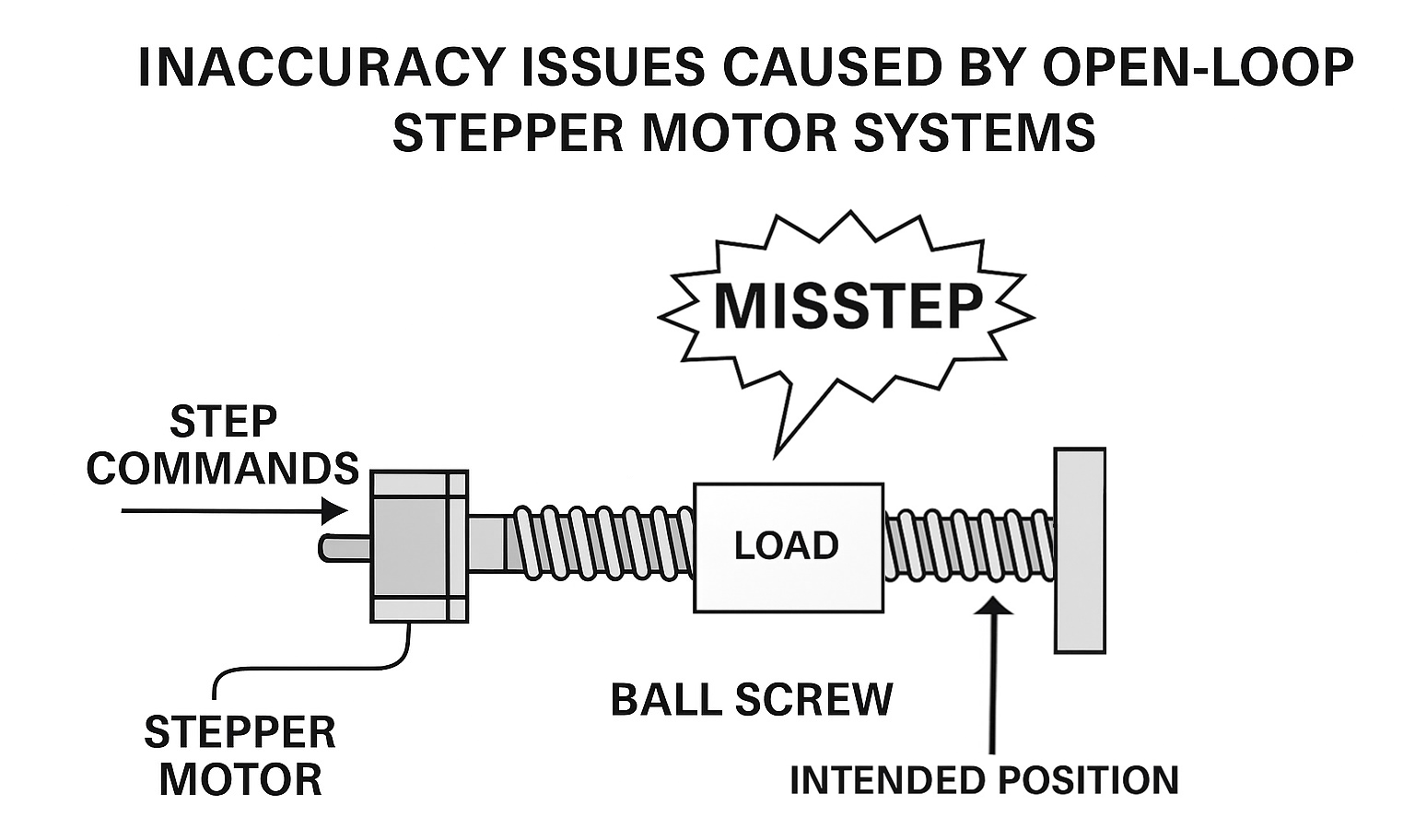

How to Achieve Micron-Level Accuracy with Stepper Motors

In high-precision automation environments like semiconductor manufacturing, even the smallest error can result in costly defects and downtime. What if you could deliver servo-like precision without the complexity or cost of servo motors?

Topics: Stepper Motors, VIDEOS, New Product Introductions, Encoders, CVD Series

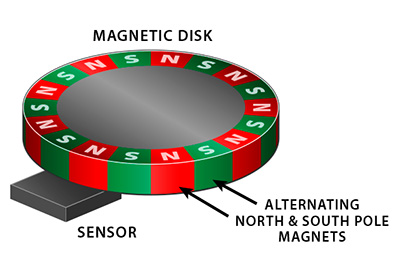

A Closer Look at Oriental Motor's Magnetic Encoders vs Optical Encoders

While optical encoders have long been the standard, magnetic encoders are emerging as a compelling alternative due to their durability, cost-efficiency, and versatility. In this article, we’ll compare the pros and cons of both encoder technologies and explain why Oriental Motor's magnetic encoders deserve a closer look for a wider range of applications.

Topics: Stepper Motors, Servo Motors, Encoders

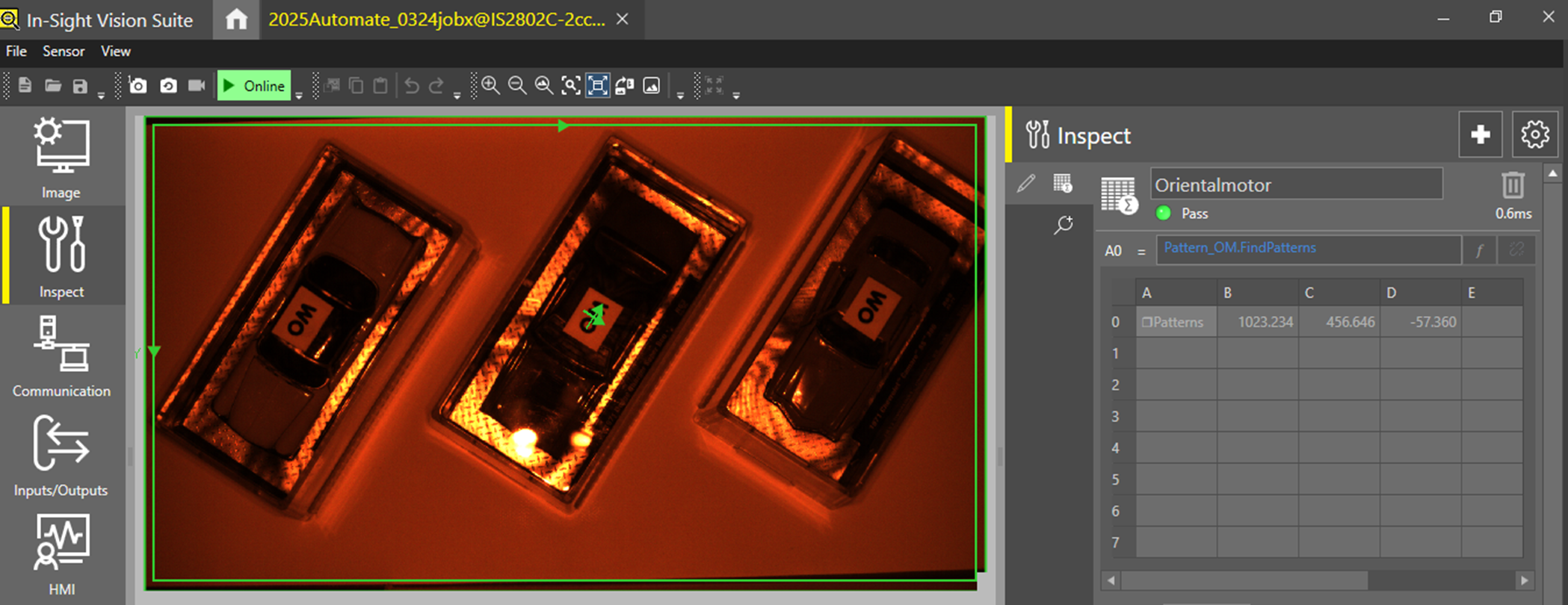

How to Unlock Vision-Based Robot Control With The MRC Studio Software

Building a robot is not easy. Programming a robot can be even more challenging without user-friendly software. In this article, I'll explain a few of the MRC Studio's most useful features and demonstrate how the Robot Vision Calibration function can help reduce costs for your vision-enabled robots.

Topics: Robotics, Software, Application Examples, Case Studies, Product Demos

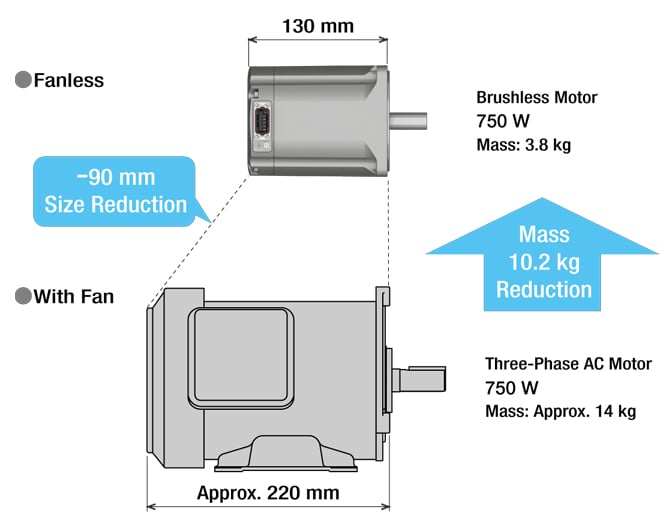

Head-to-Head: 1 HP BLDC Motor vs 1 HP AC Induction Motor

For machine designers who typically specify 3-phase AC induction motors and VFDs to meet variable speed requirements, brushless DC (BLDC) motors can be a cheat code to designing smaller, lighter, and more efficient machines. This article compares our 750 W (1 HP) Brushless DC Motor to an equivalent AC motor in efficiency, size/weight, and performance.

Topics: AC Motors, Speed Control, BLDC Motors, Application Examples, New Product Introductions

Which Cooling Fan Should You Use For Your Industrial Automation Machinery?

In industrial automation, cooling fans are used to cool electronics so that equipment can last longer. However, knowing which type of fan to apply to your machine design can be tricky. In this article, I explain how fans affect the life of electronics and compare the characteristics of the 3 most common types of cooling fans.

Topics: Cooling Fans, Application Examples

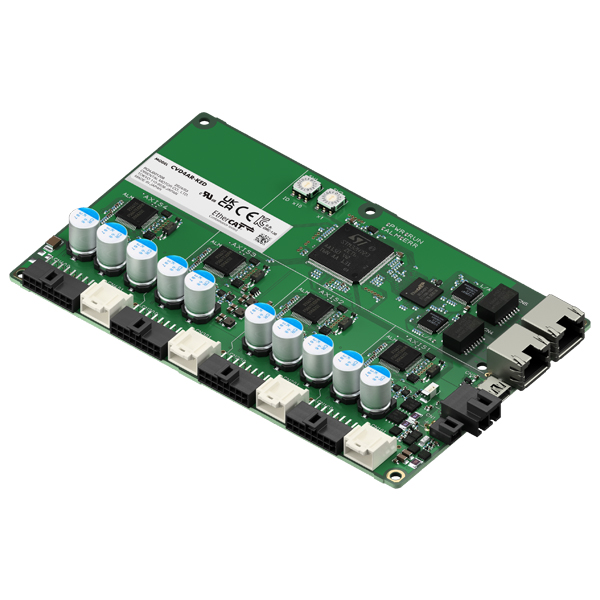

CVD Series Stepper Motor Drivers Explained

CVD Series stepper drivers are the best choice for PKP Series high-torque stepper motors due to their unique abilities to reduce different types of motor vibrations and optimize performance.

Topics: Stepper Motors, Smooth Drive, VIDEOS, CVD Series

How a Network-Compatible Multi-Axis Driver Can Simplify Design and Reduce Costs for Automated Chip Inspection

A network-compatible multi-axis driver can save space and reduce costs by combining multiple stepper motor drive circuits in a single product and minimizing the number of cables necessary for motion control.

Topics: Stepper Motors, VIDEOS, Application Examples, New Product Introductions, Semiconductors, CVD Series