Modular automation is the next phase of factory automation where a production line can be separated into mobile modules and can be quickly reconfigured for different purposes. This article explains the benefits of modular automation and shows how smaller, lighter, and battery-driven motors can help.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Topics: Stepper Motors, Robotics, Alphastep Hybrid Control, Linear Actuators, Speed Control, VIDEOS, BLDC Motors, Application Examples

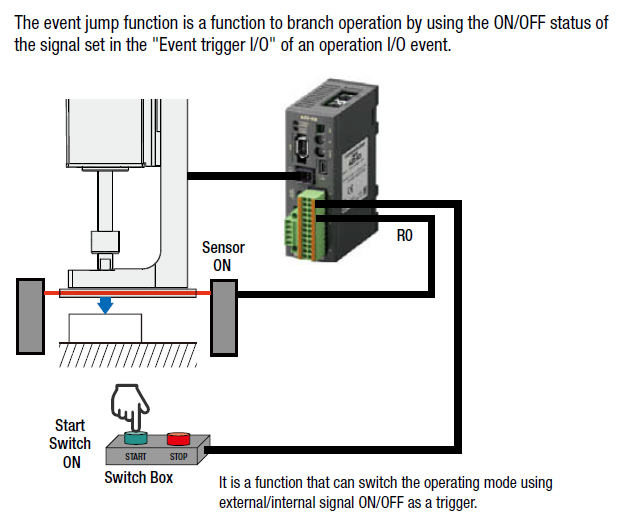

Motion Programming Example: Timed Pressing Operation

In this blog post, I will explain how to easily program a timed pressing operation with our MEXE02 universal product support software. This example works for any products included in the AlphaStep AZ Series family, which also includes other series that use the same technology and software.

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples, Motion Control Basics

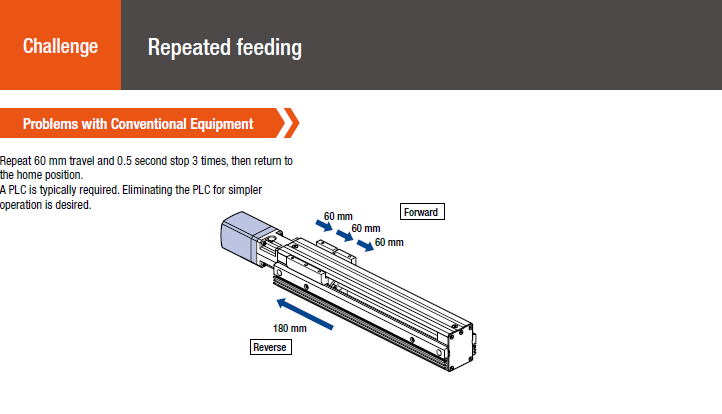

Motion Programming Example: Loop Function For Repeated Motion

No matter how many functions a product offers, without an intuitive, easy-to-use software, those functions can be difficult to implement.

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples, Motion Control Basics

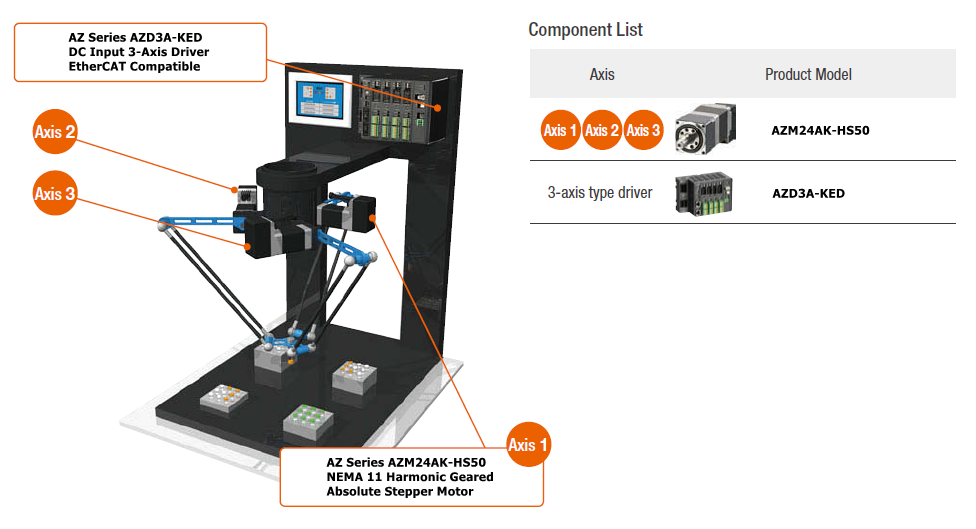

3-Axis Parallel Robot with AlphaStep Absolute Stepper Motors

Remember the days when we used to go to in-person events, such as trade shows? Robot demos have always generated a lot of foot traffic in booths. What's better to illustrate the synchronism of closed-loop stepper motors than 3 motors working together to create one specific motion?

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Gearheads, Network, Application Examples

Minimizing the Effect of Load Fluctuations for Mixers

The viscosity change in liquids can vary the torque required for mixing. For AC asynchronous motors such as AC induction motors, the rated speed is affected by load torque fluctuations, which may cause inconsistency in the final product. Is there a better motor for the job?

Topics: Speed Control, VIDEOS, BLDC Motors, Gearheads, Washdown, Application Examples

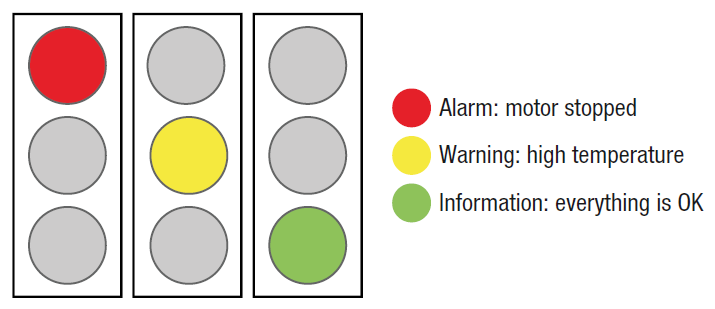

For automated factories, motor failures mean lost production and lost revenue. Being able to identify the specific issue in advance and its location is critical to maintaining production efficiency. To be successful, extra sensors must be added to detect abnormalities. There may be an easier way.

Topics: Stepper Motors, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Network, Application Examples, Troubleshooting

A gripper is typically an end effector that is installed at the end of a robotic arm or on a cartesian robot and can be used to grip parts in order to transfer them from one location to another. However, there's more to it than just closing the jaws to pinch a part.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Application Examples

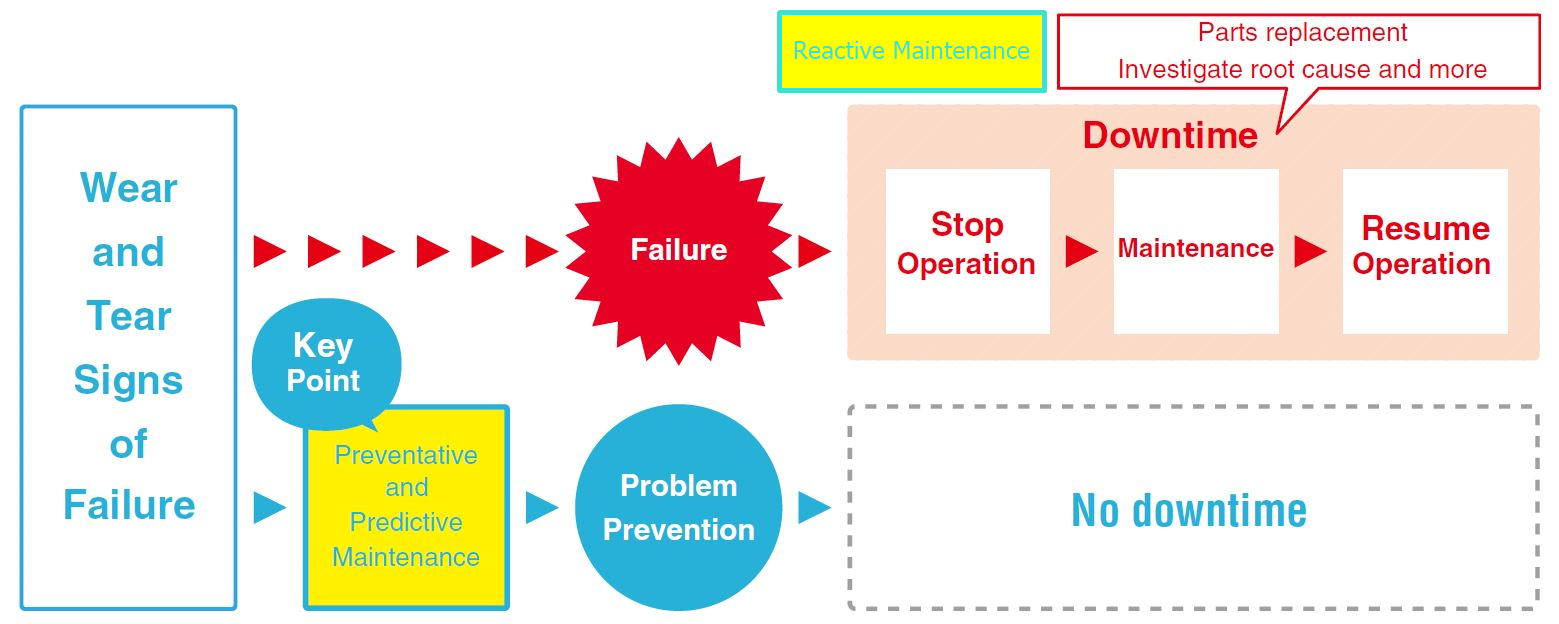

Reactive vs Preventive vs Predictive Maintenance: Why Predictive Maintenance is Better

Along with the advancement of industrial technology, maintenance methods of motion control components of a machine, such as motors, drives, and sensors, have also evolved.

Most of us still use the traditional "reactive" maintenancemethod in many aspects of life, such as replacing a dishwasher in your kitchen. People don't buy a dishwasher until theirs doesn't work anymore. Well, for factories that rely on consistent uptime for production, this wasn't the best strategy. Realizing the need for improvement, maintenance personnel started to estimate life and replace motion control components before they failed. This is called the "preventive" maintenancemethod, which also wasn't a perfect strategy for cost. More recently, with the advancement of IIoT (Industrial Internet of Things) technologies and real-time availability of status data, another method was made possible - the "predictive" maintenance method.

Topics: Stepper Motors, Linear Actuators, VIDEOS, Network, Application Examples

Robot adoption is increasing in many industries due to global efforts in reducing long term costs, maintaining quality, and freeing up time for humans to do "human" tasks. For example, by using a robot to clean floors or restock shelves in a supermarket, human employees can spend more time helping or selling to their customers. A company can either tap into this robotic trend by buying ready-made robots, or by making their own with less cost.

If engineering resources are limited, selecting the right components can reduce the difficulty and time for building a robot.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Motor Sizing, VIDEOS, Gearheads, Software, Application Examples

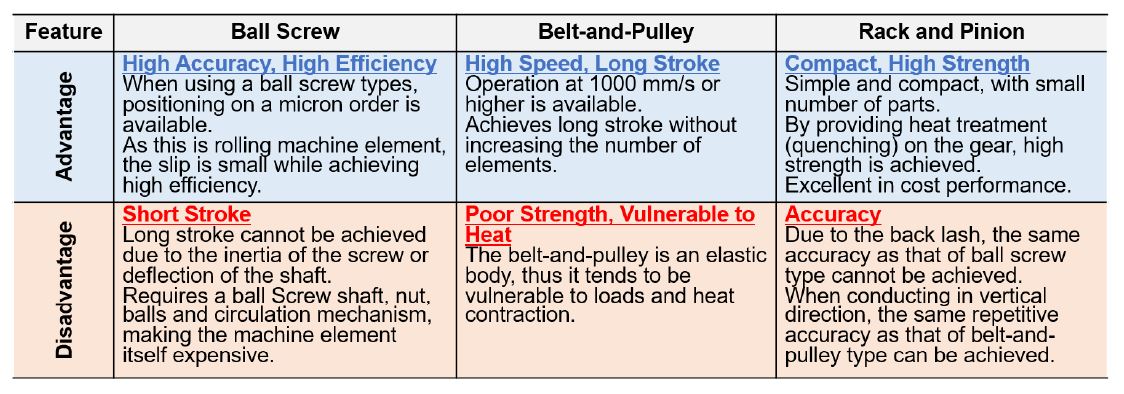

Benefits of an Absolute Rack and Pinion System Compared to Other Linear Motion Mechanisms

There are many mechanisms that convert rotary motion of an electric motor to linear motion, such as belt/chain drives, screw drives, rack & pinion drives and even CAM drives. Each mechanism offers advantages and disadvantages. Choosing the right technology can help increase load, speed, travel distance, or positioning accuracy.

Topics: Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Vertical Lifts, Application Examples