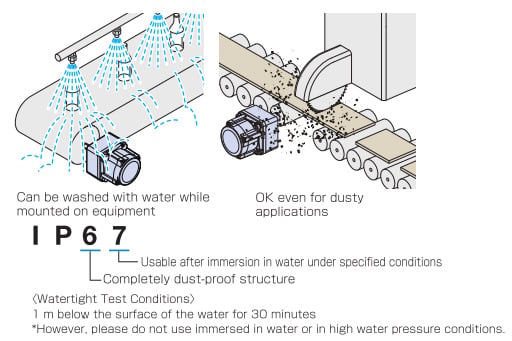

Electric motors drive our world, but they can be susceptible to environmental hazards like dust or water. This article explores IP ratings and codes, what they are, how they're tested, and why they're critical for motor durability and reliable performance.

Read More

Topics:

AC Motors,

Speed Control,

VIDEOS,

BLDC Motors,

Washdown,

Application Examples,

Motion Control Basics,

Conveyors

By adding a gearhead to a motor, a motor becomes a gear motor, and its torque is multiplied by its gear ratio and gear efficiency. However, beyond increasing torque, there are many other advantages to using gear motors.

Read More

Topics:

AC Motors,

Stepper Motors,

Absolute Positioning,

Alphastep Hybrid Control,

BLDC Motors,

Gearheads,

Application Examples,

Rotary Actuators/Index Tables

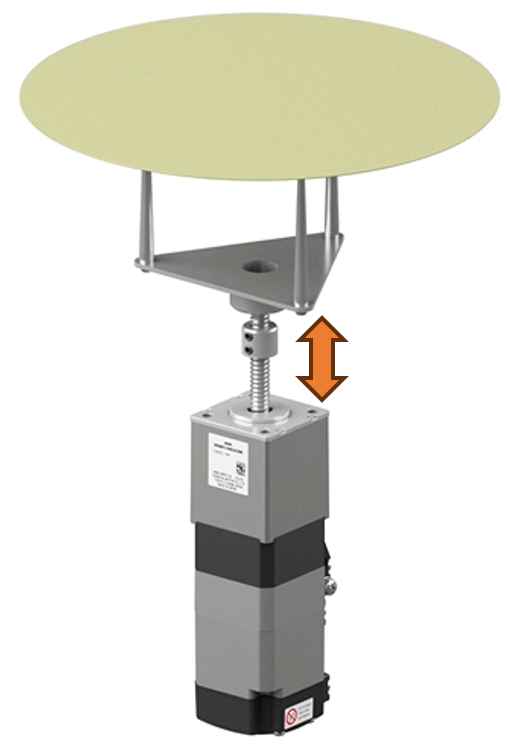

Downtime is a no no for semiconductor fabs. Even a brief interruption can result in significant financial losses and disruptions in production. In this article, we explain how a linear actuator's built-in precision and reliability can simplify and even improve the design of wafer processing machinery, such as a silicon wafer pin lift.

Read More

Topics:

Absolute Positioning,

Alphastep Hybrid Control,

Linear Actuators,

Vertical Lifts,

Application Examples,

Wafer Pin Lifters,

Semiconductors

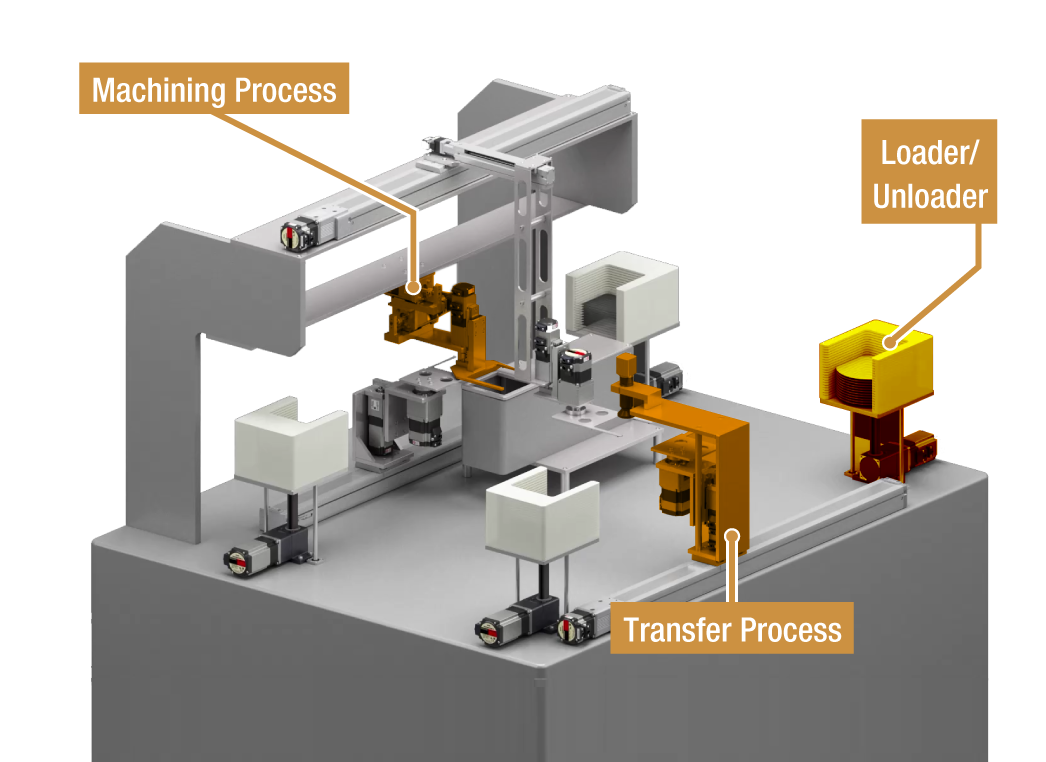

The growing demand for semiconductors, driven by technological advancements like AI, IoT, and robotics, makes it crucial to handle these delicate wafers efficiently and precisely. In this article, we will explain how unified features from a family of motors and actuators can simplify automation for semiconductor wafer manufacturing.

Read More

Topics:

Stepper Motors,

Robotics,

Absolute Positioning,

Alphastep Hybrid Control,

Linear Actuators,

VIDEOS,

Vertical Lifts,

Application Examples,

Wafer Handling,

Semiconductors

In this article, we're diving deeper into two stepper motor types: high-resolution type and encoder type; and how they can be used to improve precision in critical laboratory automation applications like autosamplers.

Read More

Topics:

Stepper Motors,

VIDEOS,

Application Examples,

Encoders,

XYZ/Cartesian/Gantry,

Medical,

Laboratory

In today's fast-paced industrial landscape, the role of conveyors has become more crucial than ever. These systems efficiently move materials, products, and goods for numerous industries, from labeling and packaging to warehousing and distribution. While many types of motors can be used in conveyors, this article highlights a few reasons why brushless motors should be a primary choice for conveyor applications.

Read More

Topics:

Speed Control,

VIDEOS,

BLDC Motors,

Application Examples,

Food & Packaging,

Semiconductors,

Conveyors

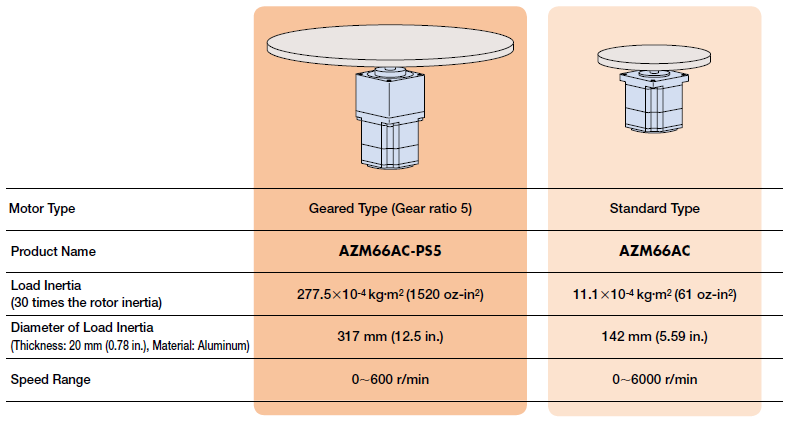

Oriental Motor provides a wide variety of products to meet semiconductor equipment design goals. This post focuses on motor selection for two specific motion axes of a semiconductor manufacturing process called CMP (Chemical Mechanical Polishing) and explains how to save time by using different products from the same family.

Read More

Topics:

Stepper Motors,

Robotics,

Absolute Positioning,

Alphastep Hybrid Control,

VIDEOS,

Gearheads,

Application Examples,

Rotary Actuators/Index Tables,

Chemical Mechanical Polishing,

Semiconductors

This article highlights the advantages of brushless motors and stepper motors for driving a peristaltic pump, which is among the most common motor applications in medical, pharmaceutical, biotech, and diagnostic equipment.

Read More

Topics:

Stepper Motors,

Speed Control,

BLDC Motors,

Pumps,

Application Examples,

Medical

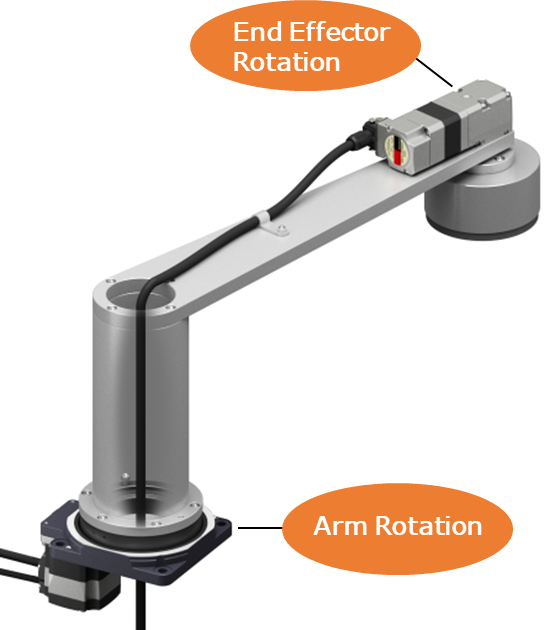

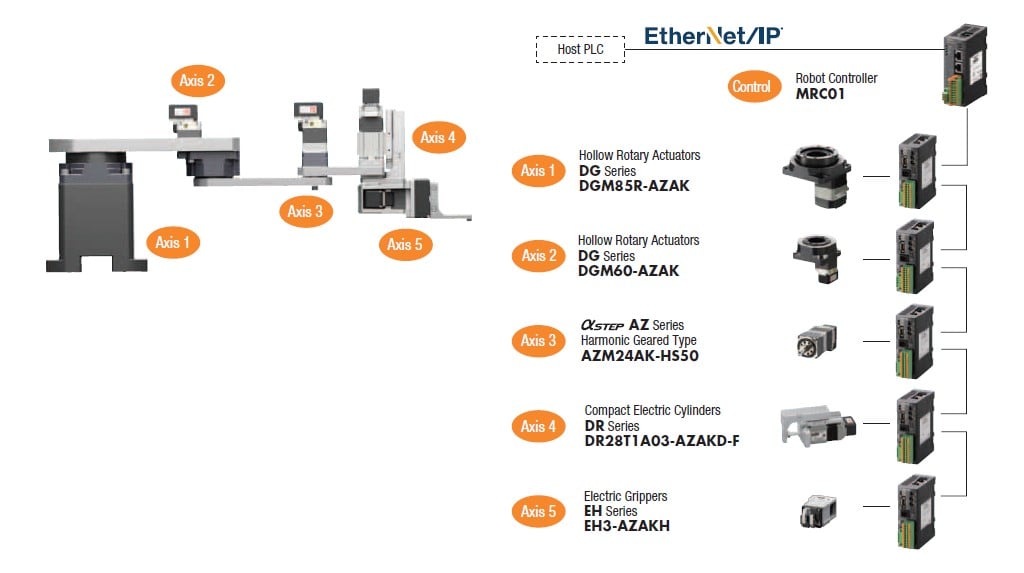

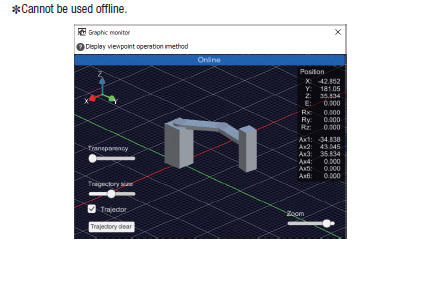

Robotics automation can be easier to build than you think. Here's an example of how a 5-axis SCARA robot can be built in-house with off-the-shelf products.

Read More

Topics:

Stepper Motors,

Robotics,

Absolute Positioning,

Alphastep Hybrid Control,

Linear Actuators,

Motor Sizing,

VIDEOS,

Software,

Network,

Application Examples,

Rotary Actuators/Index Tables

Robots are increasing in demand due to continuing labor shortages and the push for error-less efficiency in manufacturing. In the meantime, other companies are falling behind because they either do not have the capital or engineering know-how to implement robotics automation. While you can buy a robot and pay someone else to program it to do what you want, building and programming your own robot can be easier than you think.

Read More

Topics:

Stepper Motors,

Robotics,

Absolute Positioning,

Alphastep Hybrid Control,

VIDEOS,

Software,

Network,

Application Examples,

New Product Introductions

.jpg)