For applications where torque needs to be limited, an external mechanical torque limiter is typically required in addition to the motor system. When the torque exceeds the limit, the torque limiter will either decouple the load or limit the torque by slipping. An electric motor system's built-in torque limit function can simplify machine designs by eliminating this extra component.

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

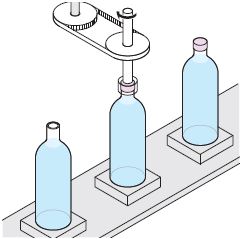

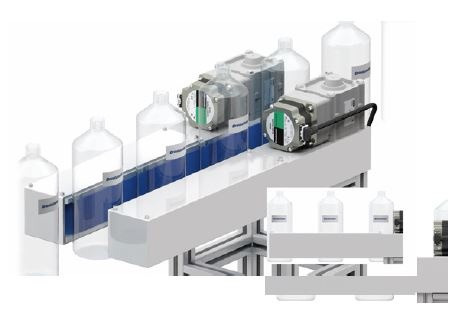

Torque Limit Application Example - Bottle Capping with BLDC Motors

Topics: Torque Limit (Push Motion, Tension Control), Speed Control, VIDEOS, BLDC Motors, Application Examples, Food & Packaging, Bottle Capping

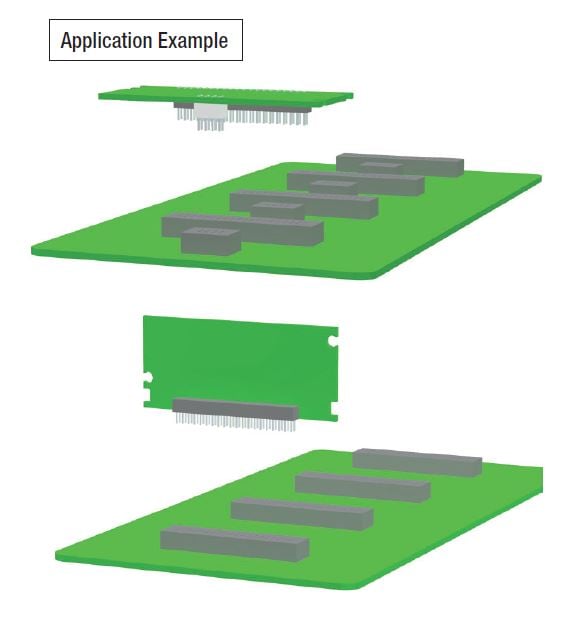

Flexible Mounting Options for Compact Stepper Motor Drivers

A driver is a must-have for any stepper motor. In a stepper motor system, a driver controls how the motor operates based on signals received from the controller. It is responsible for sending current through various phases in a stepper motor and also regulates the motor current (torque) and step resolution. With recent trends of minimizing machine footprint, finding space to install drivers could be challenging.

Standard Stepper Motor System Configuration

Topics: Stepper Motors, VIDEOS, Application Examples, CVD Series

Improve Gripping Operation with Multiple Torque Limit Settings

Robotic grippers are typically used to grip parts for transport. The driving force behind a gripper can be pneumatic, hydraulic, or electric. Which type is best for gripping?

Topics: Torque Limit (Push Motion, Tension Control), Robotics, Speed Control, VIDEOS, BLDC Motors, Application Examples, Medical, Grip Conveyors

Wrap Function: Simplified Position Control for Rotary Indexing in Absolute Coordinates

With recent trends focusing on improving engineering efficiency, many products have been developed to specifically help shorten design cycles for machine automation. Part of improving efficiency is making products easier to use, so additional time and resources can be spent elsewhere. This post describes a product feature that can make index table applications less complex to manage.

Topics: Stepper Motors, Absolute Positioning, Linear Actuators, VIDEOS, Software, Application Examples

Accelerate Design Cycles for Mobile Robots With Standard Features & Functions

In the market of electric motors, there are products designed for general purpose applications, and there are motors designed for specialized applications, such as automated guided vehicles (AGVs) or autonomous mobile robots (AMRs). While standard, general-purpose motors work for most applications such as factory automation, sometimes, it may help accelerate your design cycle by going with a motor system that already offers the features that you are planning to design into your machine. In this post, we will summarize some of these features.

Topics: Robotics, Speed Control, Motor Sizing, BLDC Motors, Gearheads, Application Examples

Improve Stepper Motor Performance Further with 3 Advanced Driver Features

There are many stepper motor manufacturers in the market place, but there are even more stepper motor driver manufacturers. The crowded market place provides many standard product options for customers to build their motion control system just the way they like it.

However, if the best possible performance is desired, it would be difficult to beat a tested combination of a specific motor and driver from the same manufacturer. By combining R&D knowledge from both motors and drivers, unique product features can be developed to improve performance further.

Topics: Stepper Motors, Smooth Drive, VIDEOS, New Product Introductions, CVD Series

Choosing the Right Type of Stepper Motor for Your Application

Stepper motors are popular for their ability to stop accurately as well as their ease of use. Both the amount of rotation and the speed are controlled easily with the same digital square wave pulse signal. Unlike servo motors, stepper motors do not need an encoder to operate. Example applications of stepper motors are CNC machines, index tables, robotics, scanners, and more recently, 3D printers.

Topics: Stepper Motors, Motor Sizing, VIDEOS, Application Examples

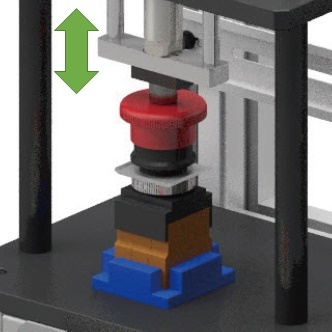

Smart System Performs Reciprocating Motion & Force Sensing Without a PLC or External Sensors

Automation is great for repetitive tasks, such as test fixtures for a process that has to repeated. In this post, we will explain how to perform a reciprocating motion (back and forth cycles) with a product that does not require a PLC or external presence sensors, which can help speed up design cycles.

Topics: Torque Limit (Push Motion, Tension Control), Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples

There are a variety of ways to synchronize the speed of multiple motors. In this blog post, we will explain another advantage of using brushless motors systems, which is its ability to set speeds accurately and be able to synchronize speeds on multiple axes easily . Brushless motors utilize built-in hall-effect sensors to regulate speed. Even if the load, input voltage, or temperature fluctuates, the speed regulation will always be under +/-0.2% or better.

Topics: AC Motors, Speed Control, VIDEOS, BLDC Motors, Washdown, Application Examples, Medical, Food & Packaging, Grip Conveyors, Conveyors

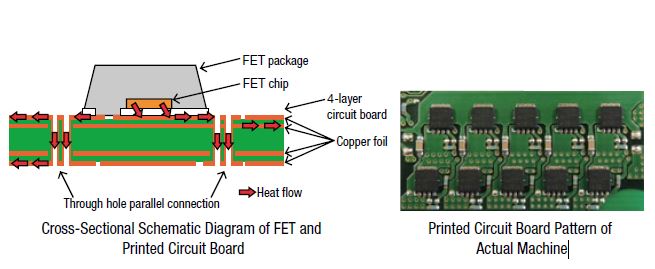

Designing Smaller and Lighter Conveyors With Brushless Motors

With the growing popularity of efficient brushless motors, replacing AC motors with these motors brings several advantages. In this blog post, we will uncover one of the advantages that can benefit lighter and compact equipment designs.

Topics: AC Motors, Speed Control, VIDEOS, BLDC Motors, Washdown, Application Examples, Medical, Food & Packaging, Grip Conveyors, Conveyors