Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

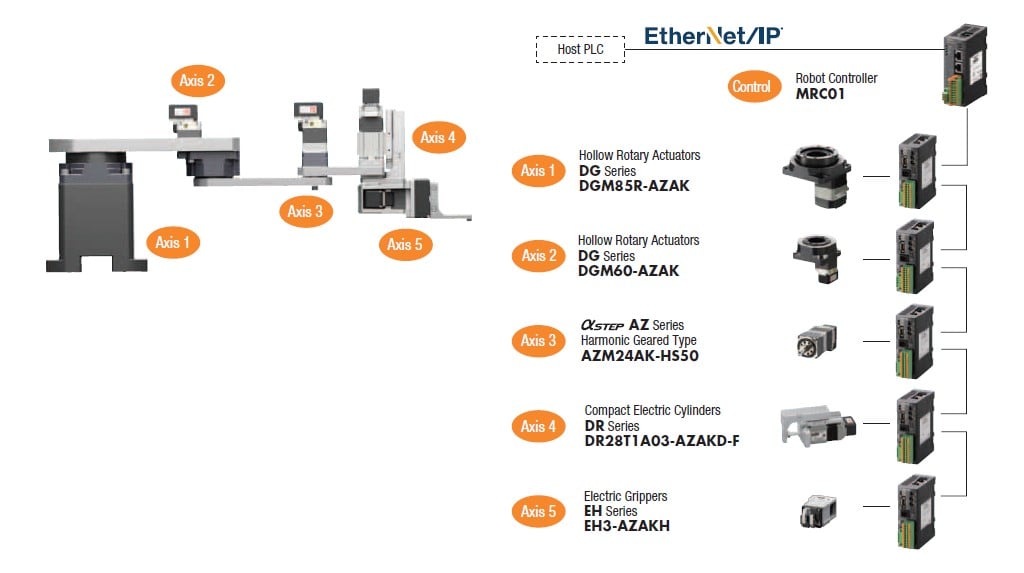

How to Build a SCARA Robot with Off-The-Shelf Products

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Motor Sizing, VIDEOS, Software, Network, Application Examples, Rotary Actuators/Index Tables

Dedicated Robot Controller and Programming Software Makes Robotics Easier

Robots are increasing in demand due to continuing labor shortages and the push for error-less efficiency in manufacturing. In the meantime, other companies are falling behind because they either do not have the capital or engineering know-how to implement robotics automation. While you can buy a robot and pay someone else to program it to do what you want, building and programming your own robot can be easier than you think.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Software, Network, Application Examples, New Product Introductions

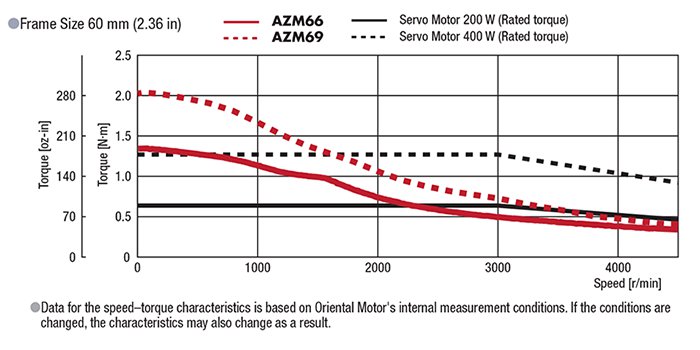

Is There an Option Between Stepper Motors and Servo Motors?

Servo motor systems are expensive but great for demanding applications that require high speed, peak torque, or feedback. Stepper motors are cost-effective but do not offer the peace of mind of feedback. For designs that do not need the bells and whistles of servo motor systems, there is another option.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Servo Motors, Network

Case Study: SCARA and Cartesian/Gantry Robots for Automated Assembly

In this post, we introduce a real-world SCARA and cartesian/gantry robot example of in-house automation built using our AlphaStep AZ Series family of motors, actuators, drivers, and our 4-axis robot controller.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Software, Rotary Actuators/Index Tables, XYZ/Cartesian/Gantry, Case Studies

Modular automation is the next phase of factory automation where a production line can be separated into mobile modules and can be quickly reconfigured for different purposes. This article explains the benefits of modular automation and shows how smaller, lighter, and battery-driven motors can help.

Topics: Stepper Motors, Robotics, Alphastep Hybrid Control, Linear Actuators, Speed Control, VIDEOS, BLDC Motors, Application Examples

Video Explainer: How the BLV Series R Type Can Improve AGV/AMR Design and Performance

The BLV Series R Type brushless DC motor and compact driver not only reduces the size and weight of the original BLV Series driver but offer an upgrade to the motor as well. This blog post uses videos to explain the features offered by the BLV Series R Type and how they can improve AGV/AMR design and performance.

Topics: Robotics, Smooth Drive, Speed Control, VIDEOS, BLDC Motors, Software, Network

The BLV Series is one of two DC-input brushless motor speed control systems we offer. While a brushless motor with hall-effect sensor feedback provides constant torque, wide speed range, and speed regulation, the BLV driver offers unique functions designed for mobile robots, such as low battery operation and ramp operation.

Topics: Robotics, Speed Control, BLDC Motors, Software, Network, Troubleshooting

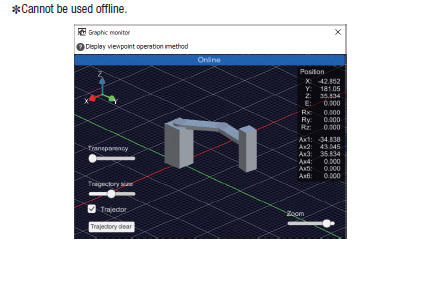

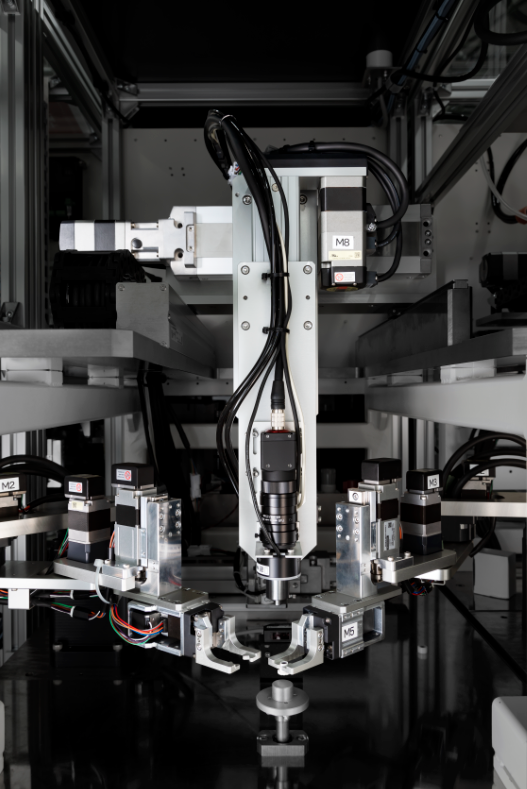

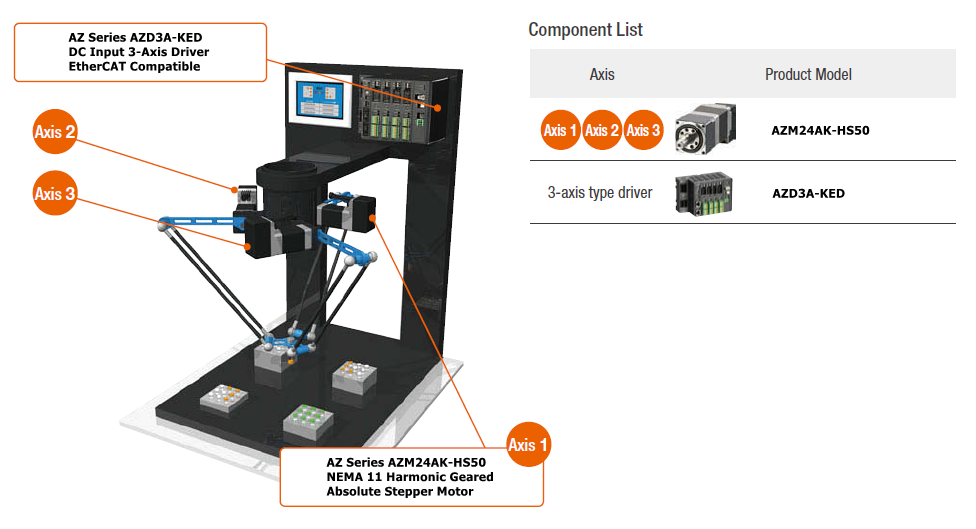

3-Axis Parallel Robot with AlphaStep Absolute Stepper Motors

Remember the days when we used to go to in-person events, such as trade shows? Robot demos have always generated a lot of foot traffic in booths. What's better to illustrate the synchronism of closed-loop stepper motors than 3 motors working together to create one specific motion?

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Gearheads, Network, Application Examples

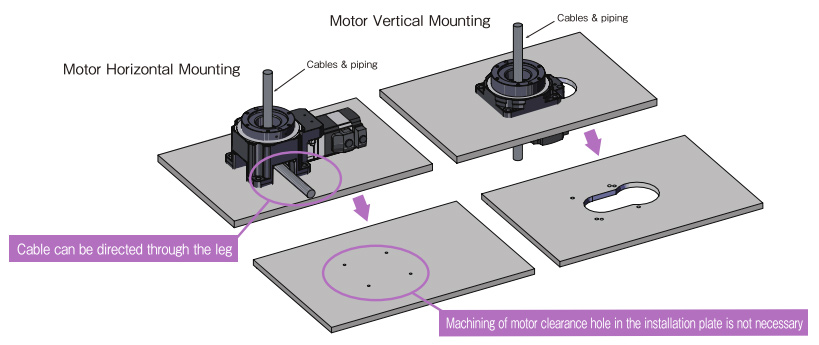

Flexible Configurations For Hollow Rotary Actuators

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Gearheads, Rotary Actuators/Index Tables

A gripper is typically an end effector that is installed at the end of a robotic arm or on a cartesian robot and can be used to grip parts in order to transfer them from one location to another. However, there's more to it than just closing the jaws to pinch a part.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Application Examples