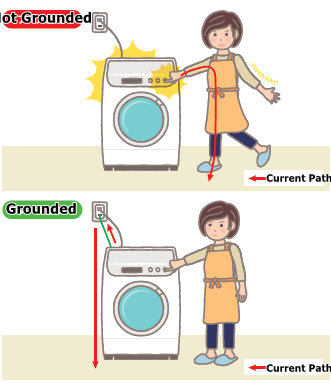

Proper grounding is necessary for electrical devices for different reasons, but why do we do it?

Welcome to Oriental Motor's "Engineering Notes" Blog:

Products and technology are only valuable when coupled with skilled people and services to support them. Since 1978, ORIENTAL MOTOR U.S.A. CORP. has been building a service and support system to better serve customers. It is our goal to provide the best product and service from the design phase, through the sale and beyond.

Our blog will feature:

- Introduction to new products and technologies

- Motion control basics and application examples

- Tips for motor selection, programming, and troubleshooting

Grounding Basics: What are the Differences Between PE and FG?

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, BLDC Motors, Servo Motors, Cooling Fans, Motion Control Basics

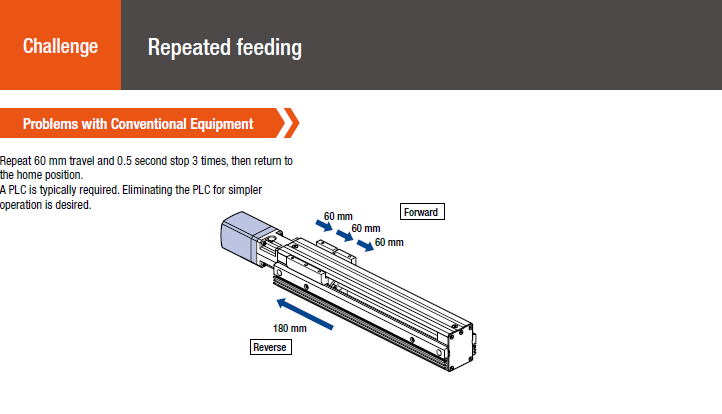

Motion Programming Example: Loop Function For Repeated Motion

No matter how many functions a product offers, without an intuitive, easy-to-use software, those functions can be difficult to implement.

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Software, Application Examples, Motion Control Basics

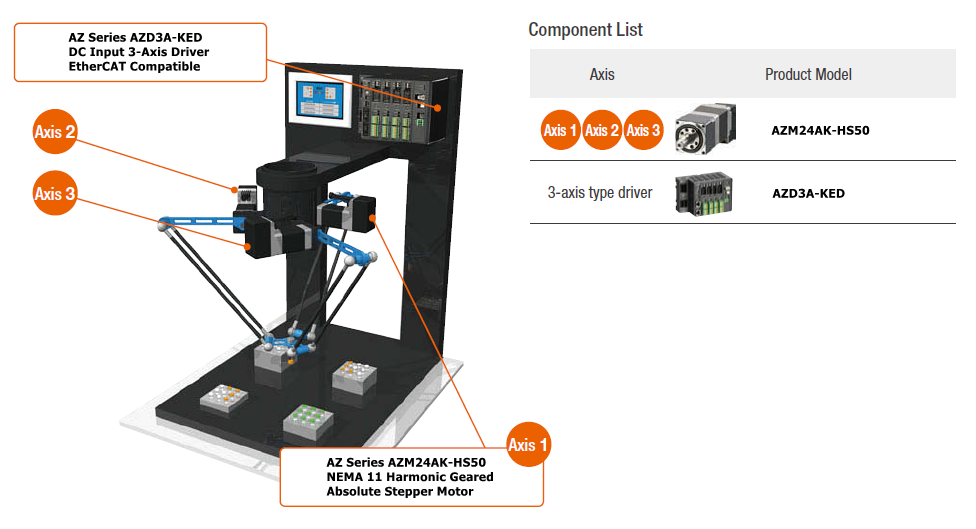

3-Axis Parallel Robot with AlphaStep Absolute Stepper Motors

Remember the days when we used to go to in-person events, such as trade shows? Robot demos have always generated a lot of foot traffic in booths. What's better to illustrate the synchronism of closed-loop stepper motors than 3 motors working together to create one specific motion?

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, VIDEOS, Gearheads, Network, Application Examples

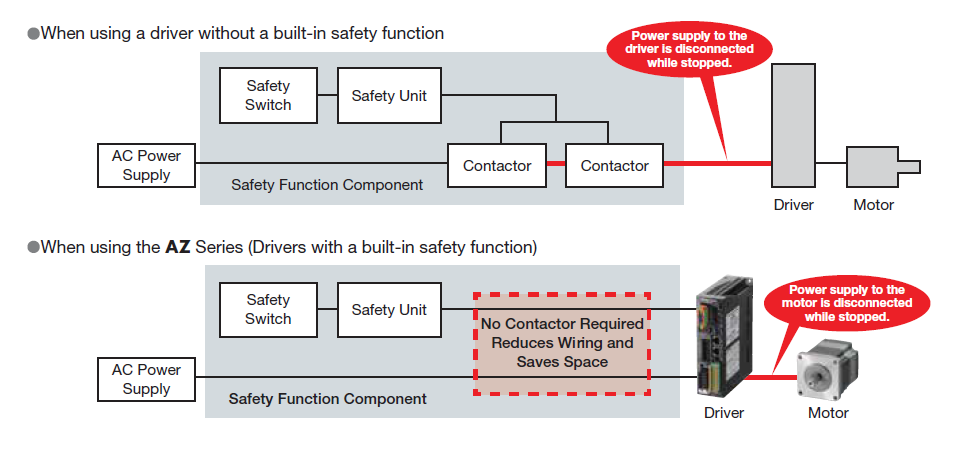

STO, or "Safe Torque Off", is a dedicated, built-in safety circuit function that makes safety easier to manage for motion devices, such as an industrial robot. It is part of the overall safety system designed to prevent injuries or damage.

Topics: Stepper Motors, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators

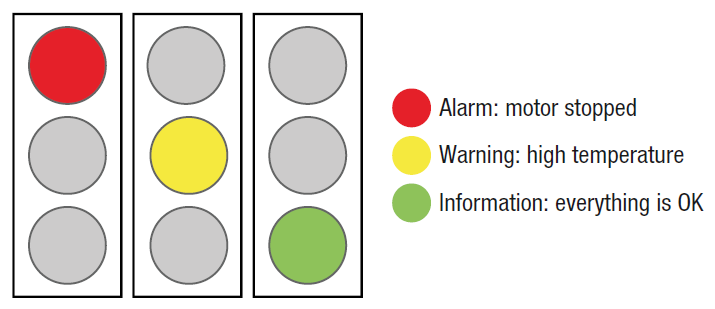

For automated factories, motor failures mean lost production and lost revenue. Being able to identify the specific issue in advance and its location is critical to maintaining production efficiency. To be successful, extra sensors must be added to detect abnormalities. There may be an easier way.

Topics: Stepper Motors, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Network, Application Examples, Troubleshooting

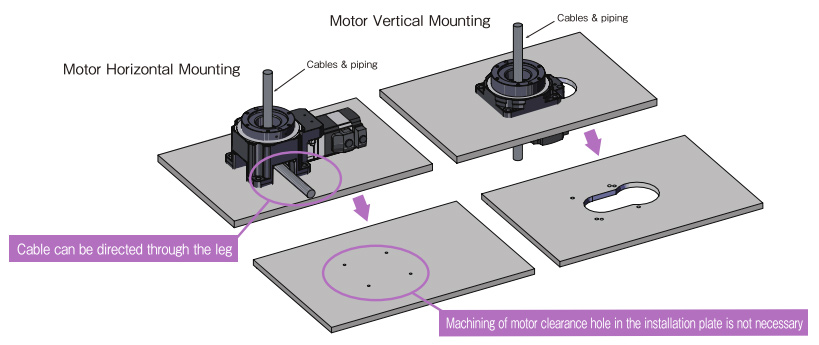

Flexible Configurations For Hollow Rotary Actuators

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, Gearheads, Rotary Actuators/Index Tables

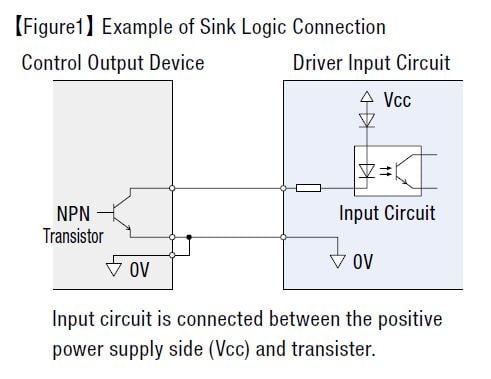

Control Basics: The Difference Between Sink and Source Logic

For someone who has never had experience wiring I/O for motion control, it can be scary the first time. If devices are not wired correctly, it can cause a range of issues from a motor simply not doing what's expected to irreversible product damage. I still get that nervous feeling before I press the START button on a demo. Murphy's Law, anyone?

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, BLDC Motors, Servo Motors, Motion Control Basics

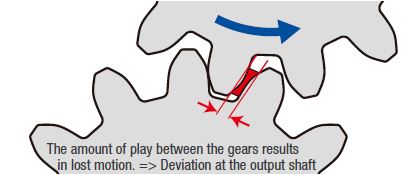

The significance of position control accuracy of motors varies depending on the application. For an AGV in a farm with DC motor-driven wheels, position control accuracy is probably not as crucial as a surgical robot where incisions are controlled by servo motors or stepper motors.

Topics: Stepper Motors, Alphastep Hybrid Control, Gearheads, Servo Motors, Motion Control Basics

A gripper is typically an end effector that is installed at the end of a robotic arm or on a cartesian robot and can be used to grip parts in order to transfer them from one location to another. However, there's more to it than just closing the jaws to pinch a part.

Topics: Stepper Motors, Robotics, Absolute Positioning, Alphastep Hybrid Control, Linear Actuators, VIDEOS, Application Examples

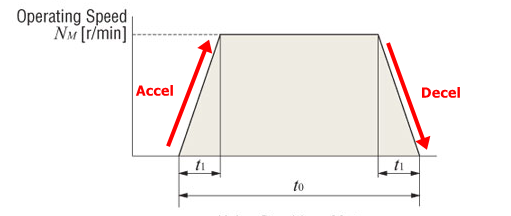

Motor Sizing Basics Part 3: How to Calculate Speed, Acceleration Torque, and RMS Torque

Now that we understand the calculations behind load torque and load inertia, we're a little closer to motor selection. You might be wondering why I separated load torque and acceleration torque calculations. That's because in order to calculate for acceleration torque, load inertia and speed must be calculated first.

Topics: AC Motors, Stepper Motors, Alphastep Hybrid Control, Linear Actuators, Speed Control, Motor Sizing, BLDC Motors, Servo Motors, Motion Control Basics